Roof-purpose multi-color room-temperature waterproof material and construction process thereof

A technology of waterproof materials and construction techniques, applied in the direction of roof insulation materials, building roofs, roof coverings, etc., can solve the problems of unclean base surface, high risk factor of high-altitude operations, and difficult to determine water leakage points, etc., to achieve reduction of cement Concrete protective layer, low overall project cost, and convenient post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

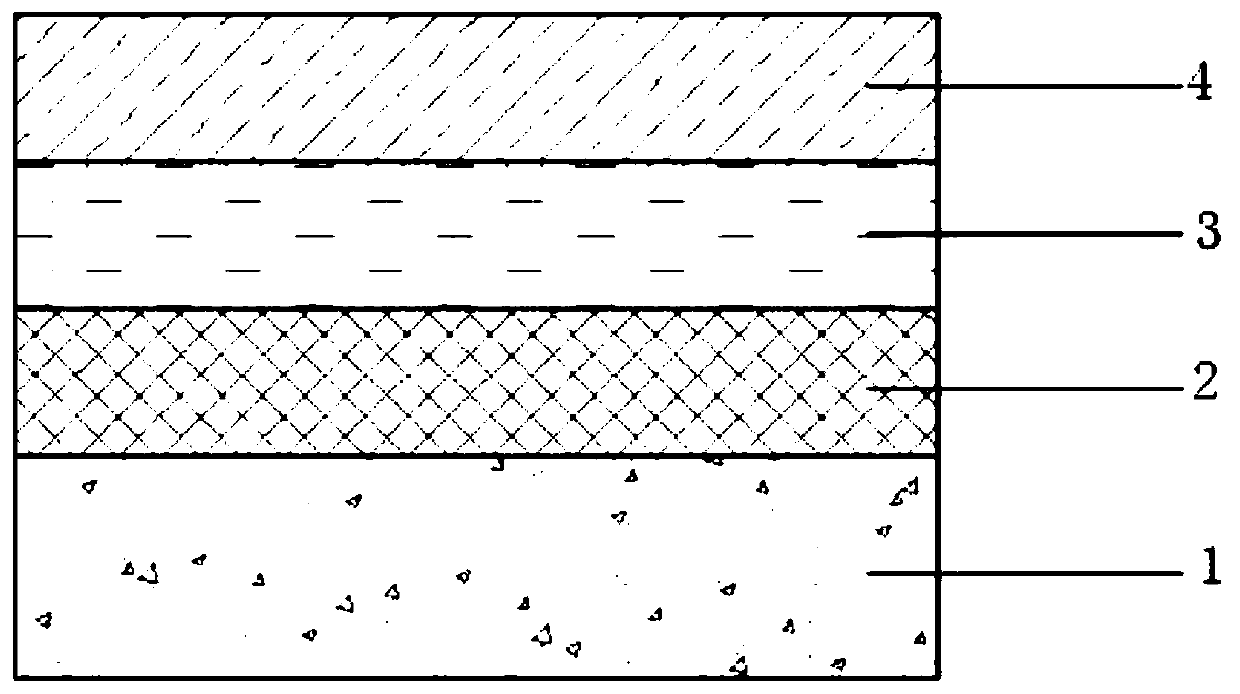

[0032] Such as figure 1 As shown, a multi-color room temperature waterproof material and construction technology for the roof, including a cement-based solidified layer 1, the top of the cement-based solidified layer 1 is roll-coated with a waterproof bonding bottom layer 2, and the waterproof bonding bottom layer 2 is scratch-coated with waterproof and wear-resistant Surface layer 3, roll-coat weather-resistant color protection layer 4 on the waterproof and wear-resistant surface layer 3.

[0033] The waterproof and wear-resistant surface layer mainly includes the following components in parts by weight: waterproof asphalt mixed mortar prepared by mixing 4 parts of composite modified emulsified decolorized asphalt, 10 parts of high stiffness mixed additive and 0.5 part of water.

[0034] The bonding strength of the composite modified emulsified decolorized asphalt is greater than 1Mpa, the softening point is less than 78°C, the 5-degree ductility is greater than 80cm, and the...

specific Embodiment 2

[0046] Such as figure 1 As shown, a multi-color room-temperature waterproof material and construction technology for the roof, including a cement-based surface solidified layer 1, the top of the cement-based surface solidified layer 1 is roll-coated with a waterproof bonding bottom layer 2, and the waterproof bonding bottom layer 2 is scratch-coated waterproof and wear-resistant Surface layer 3, roll-coat weather-resistant color protection layer 4 on the waterproof and wear-resistant surface layer 3.

[0047] The waterproof and wear-resistant surface layer mainly includes the following components in parts by weight: waterproof asphalt mixed mortar prepared by mixing 8 parts of composite modified emulsified decolorized asphalt, 14 parts of high-stiffness mixed additives and 1.5 parts of water.

[0048] The bonding strength of the composite modified emulsified decolorized asphalt is greater than 1Mpa, the softening point is less than 78°C, the 5-degree ductility is greater than ...

specific Embodiment 3

[0060] Such as figure 1 As shown, a multi-color room-temperature waterproof material and construction technology for the roof, including a cement-based surface solidified layer 1, the top of the cement-based surface solidified layer 1 is roll-coated with a waterproof bonding bottom layer 2, and the waterproof bonding bottom layer 2 is scratch-coated waterproof and wear-resistant Surface layer 3, roll-coat weather-resistant color protection layer 4 on the waterproof and wear-resistant surface layer 3.

[0061] The waterproof and wear-resistant surface layer mainly includes the following components in parts by weight: waterproof asphalt mixed mortar prepared by mixing 6 parts of composite modified emulsified decolorized asphalt, 12 parts of high stiffness mixed additives and 1 part of water.

[0062] The bonding strength of the composite modified emulsified decolorized asphalt is greater than 1Mpa, the softening point is less than 78°C, the 5-degree ductility is greater than 80c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com