H-shaped steel-concrete composite beam sub-stress adjusting device and adjusting method thereof

A technology of I-shaped steel and adjustment method, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of affecting the internal force state of the structure, weak structural rigidity, installation accuracy error, etc., so as to improve the service life of the structure and improve the stress of the structure. state, the effect of enhancing crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

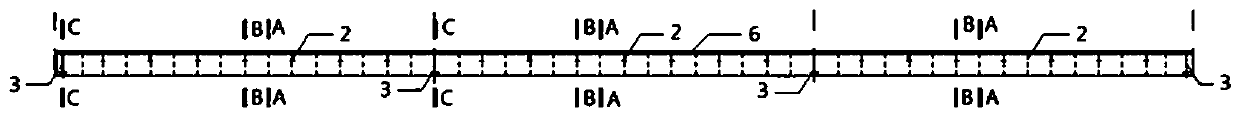

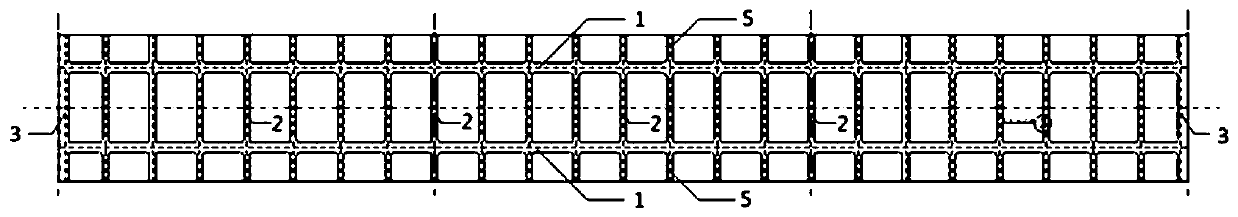

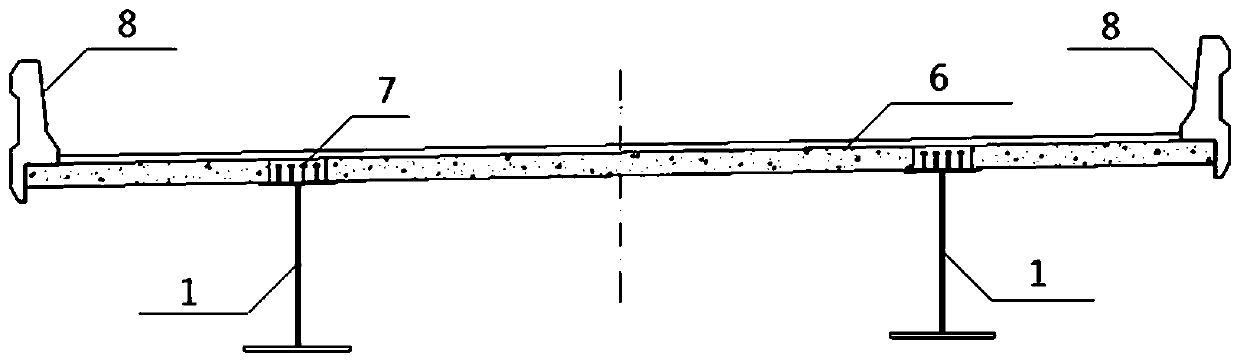

[0043] Figure 1~4It is the overall elevation, plan and cross-sectional view of the three-span continuous composite beam. The composite beam is composed of a steel main beam, a concrete bridge deck 6, and shear nails 7. The steel main beam consists of two I-shaped main beams 1 and small and medium-span beams 2. The fulcrum beam 3 and the cantilever beam 5 are composed. The steel main beam is connected with the concrete bridge deck 6 through shear nails 7 to form a combined structure.

[0044] The steel main girder of the composite beam is manufactured in the factory and connected by full welding on site. Since the main steel girder adopts an I-shaped opening section, during the installation of the steel structure, due to the fact that it has not yet formed a combined structure with concrete, the structural rigidity is weak, coupled with the influence of boundary conditions such as installation accuracy errors and differential settlement of the brackets during the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com