Method and device for manufacturing gallium arsenide polycrystals

A manufacturing method and technology of gallium arsenide, applied in the field of polycrystalline synthesis, can solve the problems of short service life of boron nitride boat and high breakage rate of the nozzle of quartz tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

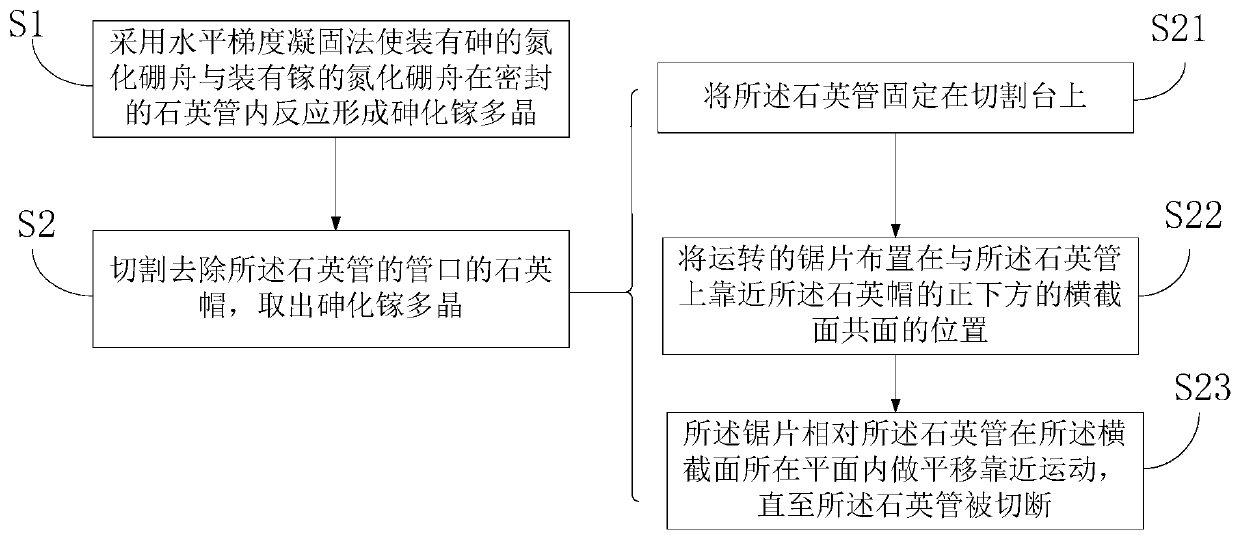

Method used

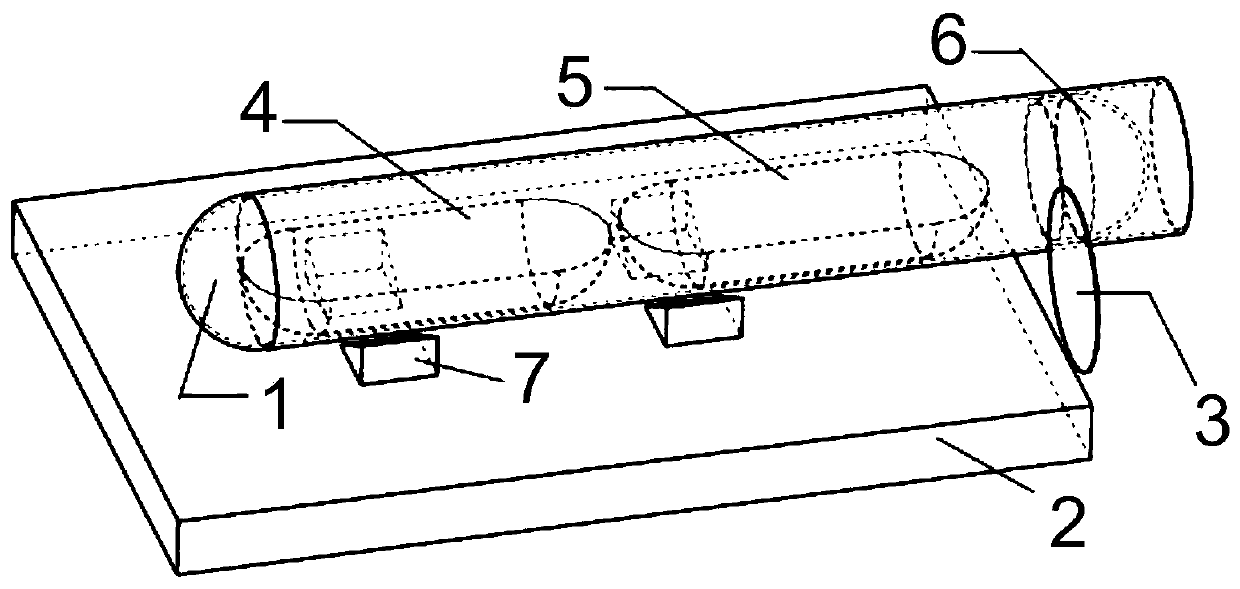

Image

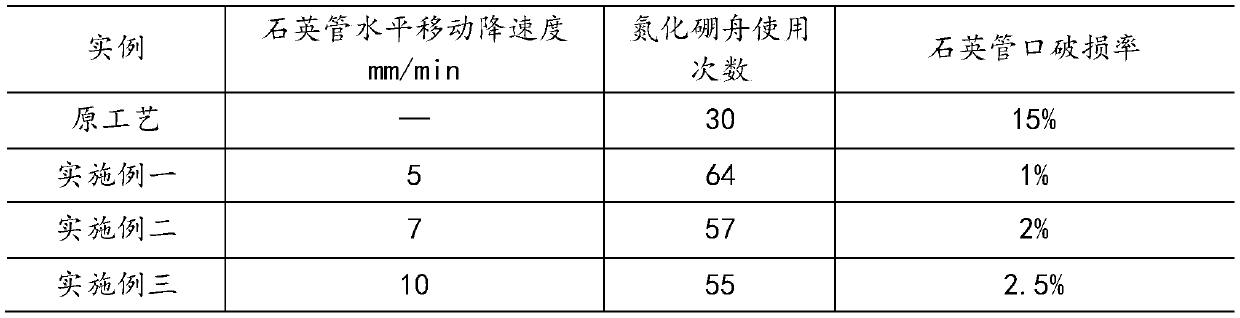

Examples

Embodiment 1

[0055] (1) Loading: Put 6N arsenic and 6N gallium in a boron nitride boat, then put them into a quartz tube, and put a quartz cap at the mouth of the quartz tube.

[0056] (2) Quartz tube seal welding: weld the quartz tube and the quartz cap with a hydrogen-oxygen flame to connect the two together.

[0057] (3) Furnace loading: put the quartz tube containing arsenic and gallium into the synthesis furnace, insert Tc in the corresponding position, and plug asbestos at both ends of the synthesis furnace.

[0058] (4) Heating the melting material: after baking the material, close the vacuum valve, heat up, and make the arsenic vapor and gallium synthesize gallium arsenide polycrystalline liquid at high temperature.

[0059] (5) Polycrystalline synthetic growth: the temperature curve is controlled by the program, so that the temperature of the quartz tube filled with arsenic and gallium is gradually reduced from the beginning to the end, so that the synthesized gallium arsenide liq...

Embodiment 2

[0064] (1) Loading: Put 6N arsenic and 6N gallium in a boron nitride boat, then put them into a quartz tube, and put a quartz cap at the mouth of the quartz tube.

[0065] (2) Quartz tube seal welding: weld the quartz tube and the quartz cap with a hydrogen-oxygen flame to connect the two together.

[0066] (3) Furnace loading: Put the quartz tube containing arsenic and gallium into the synthesis furnace, insert Tc at the corresponding position, and plug asbestos at both ends of the synthesis path.

[0067] (4) Heating the melting material: after baking the material, close the vacuum valve, heat up, and make the arsenic vapor and gallium synthesize gallium arsenide polycrystalline liquid at high temperature.

[0068] (5) Polycrystalline synthetic growth: the temperature curve is controlled by the program, so that the temperature of the quartz tube filled with arsenic and gallium is gradually decreased from the beginning to the end, so that the synthesized gallium arsenide liqu...

Embodiment 3

[0073] (1) Loading: Put 6N arsenic and 6N gallium in a boron nitride boat, then put them into a quartz tube, and put a quartz cap at the mouth of the quartz tube.

[0074] (2) Quartz tube seal welding: weld the quartz tube and the quartz cap with a hydrogen-oxygen flame to connect the two together.

[0075] (3) Furnace loading: Put the quartz tube containing arsenic and gallium into the synthesis furnace, insert Tc at the corresponding position, and plug asbestos at both ends of the synthesis path.

[0076] (4) Heating the melting material: after baking the material, close the vacuum valve, heat up, and make the arsenic vapor and gallium synthesize gallium arsenide polycrystalline liquid at high temperature.

[0077] (5) Polycrystalline synthetic growth: the temperature curve is controlled by the program, so that the temperature of the quartz tube filled with arsenic and gallium is gradually decreased from the beginning to the end, so that the synthesized gallium arsenide liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com