A zinc-based composite coating with rapid repair ability and its preparation method and application

A composite coating, zinc-based technology, used in transportation and packaging, metal processing equipment, pressure inorganic powder coating, etc., can solve problems such as poor self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of Zn-0.1wt% rGo / Al coating

[0035] 1. Prepare rGo / Al powder with a concentration of 0.1wt% by in-situ reduction method, and the preparation steps are as follows:

[0036] (1) According to the concentration of 0.2mg graphene oxide / 1mlDI water, take 20mg graphene oxide and ultrasonically disperse in 100mlDI water, prepare the graphene oxide dispersion liquid that pH is 4.0;

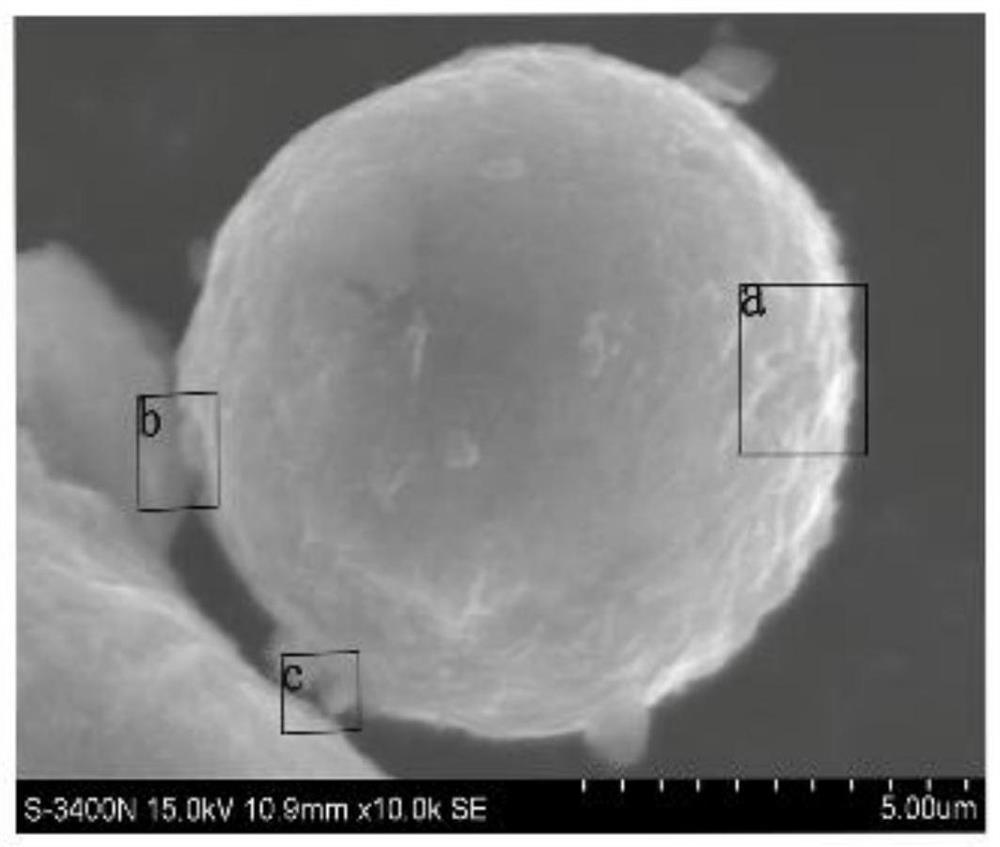

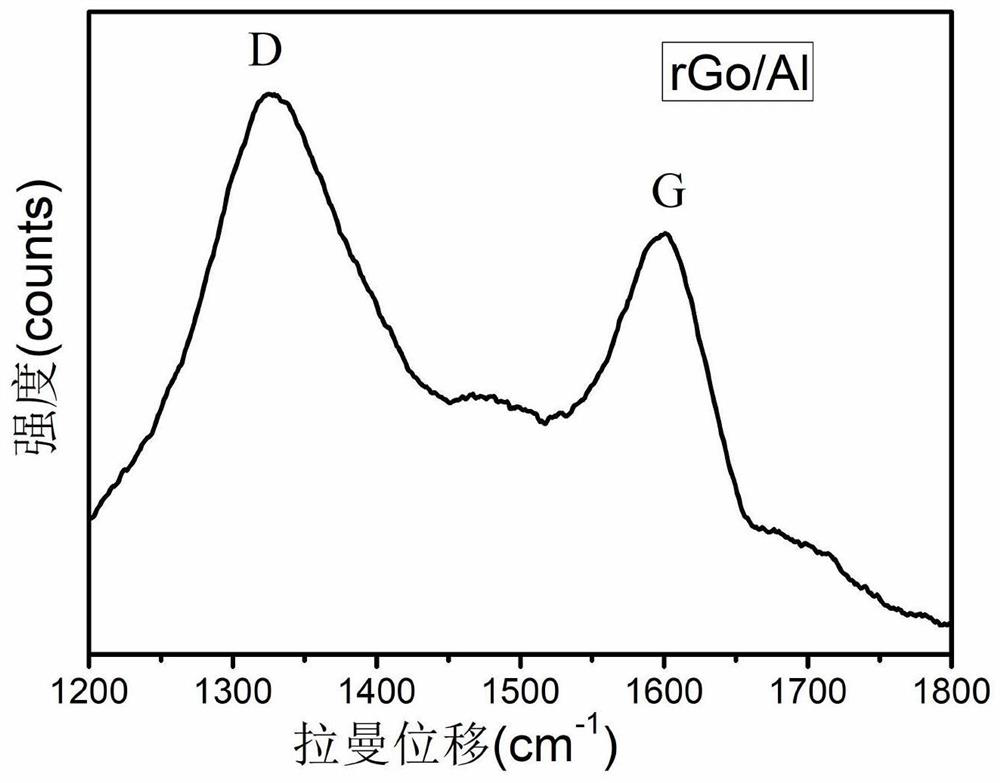

[0037] (2) In the graphene oxide dispersion in (1), add 20 g of spherical aluminum powder with a particle size of 10 to 30 μm, stir until the solution is clear, filter the solution, and obtain a reduced graphene oxide-coated aluminum with a concentration of 0.1 wt%. pink;

[0038] (3) Transfer the reduced graphene oxide-coated aluminum powder obtained in (2) to the ethanol solution, and magnetically stir for 3 minutes;

[0039] (4) Filter the reduced graphene oxide-coated aluminum powder washed with ethanol in (3) and then vacuum-dry it at 50° C. for 8 hours to obtain dry re...

Embodiment 2

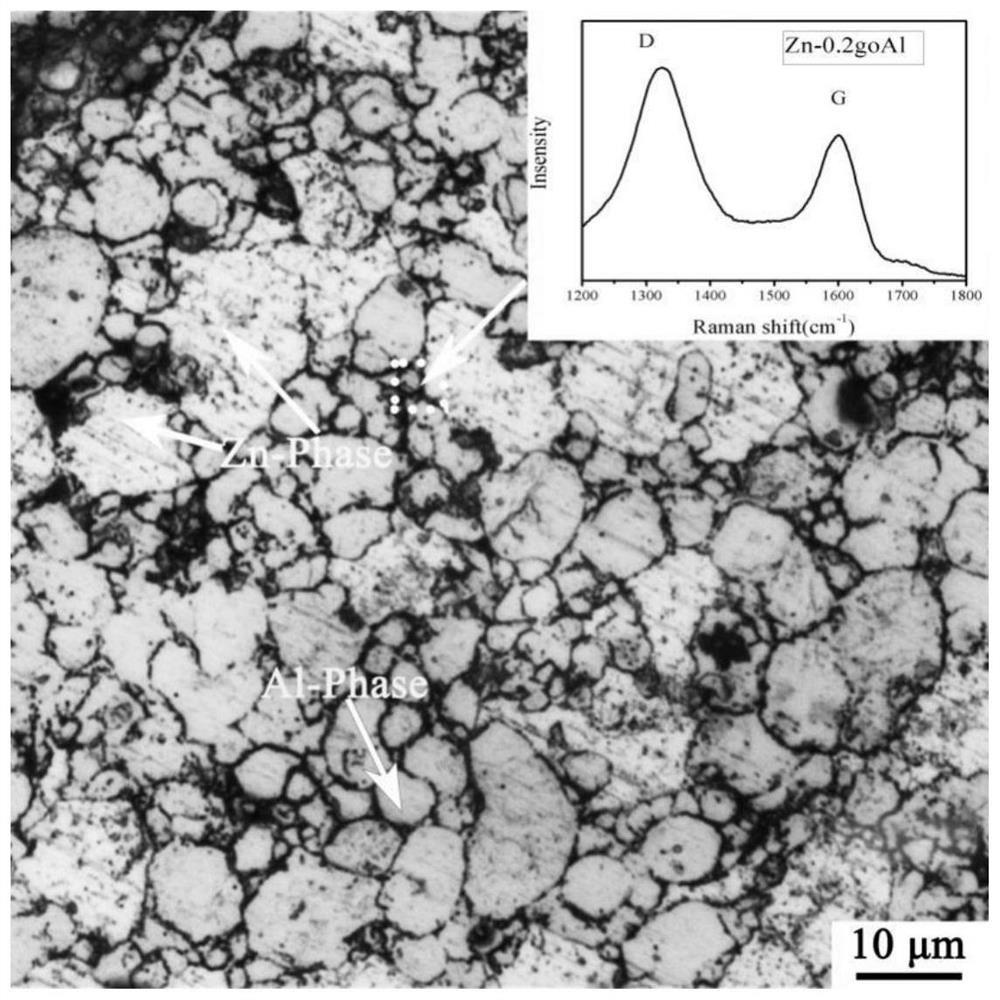

[0043] Example 2 Preparation of Zn-0.2wt% rGo / Al coating

[0044] 1. Prepare rGo / Al powder with a concentration of 0.2wt% by in-situ reduction method, and the preparation steps are as follows:

[0045] (1) According to the concentration of 0.2mg graphene oxide / 1mlDI water, 40mg graphene oxide is ultrasonically dispersed in 200mlDI water, and the pH of the prepared dispersion is 4.0 graphene oxide dispersion;

[0046] (2) In the graphene oxide dispersion in (1), add 20 g of spherical aluminum powder with a particle size of 10 to 30 μm, stir until the solution is clear, filter the solution, and obtain a reduced graphene oxide coating with a concentration of 0.2 wt%. aluminum powder;

[0047] (3) Transfer the reduced graphene oxide-coated aluminum powder obtained in (2) to the ethanol solution, and magnetically stir for 3 minutes;

[0048] (4) Filter the reduced graphene oxide-coated aluminum powder washed with ethanol in (3), and vacuum-dry at 50° C. for 8 hours to obtain dry ...

Embodiment 3

[0053] Example 3 Preparation of Zn-0.3wt% rGo / Al coating

[0054] 1. Prepare rGo / Al powder with a concentration of 0.3wt% by in-situ reduction method, and the preparation steps are as follows:

[0055] (1) According to the concentration of 0.2mg graphene oxide / 1mlDI water, 60mg graphene oxide is ultrasonically dispersed in 300mlDI water, and the pH of the prepared dispersion is 4.0 graphene oxide dispersion;

[0056] (2) In the graphene oxide dispersion in (1), add 20 g of spherical aluminum powder with a particle size of 10 to 30 μm, stir until the solution is clear, filter the solution, and obtain a concentration of 0.3 wt% reduced graphene oxide coated aluminum pink;

[0057] (3) Transfer the reduced graphene oxide-coated aluminum powder obtained in (2) to the ethanol solution, and magnetically stir for 3 minutes;

[0058] (4) Filter the reduced graphene oxide-coated aluminum powder washed with ethanol in (3), and vacuum-dry at 50° C. for 8 hours to obtain dry reduced gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com