Antibacterial foaming sole and preparation method thereof

A technology for insoles and raw materials, applied in the field of antibacterial foamed soles and their preparation, can solve the problems of poor elasticity, poor antibacterial effect, and irritating taste, and achieve the effects of preventing foot odor, good antibacterial effect, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

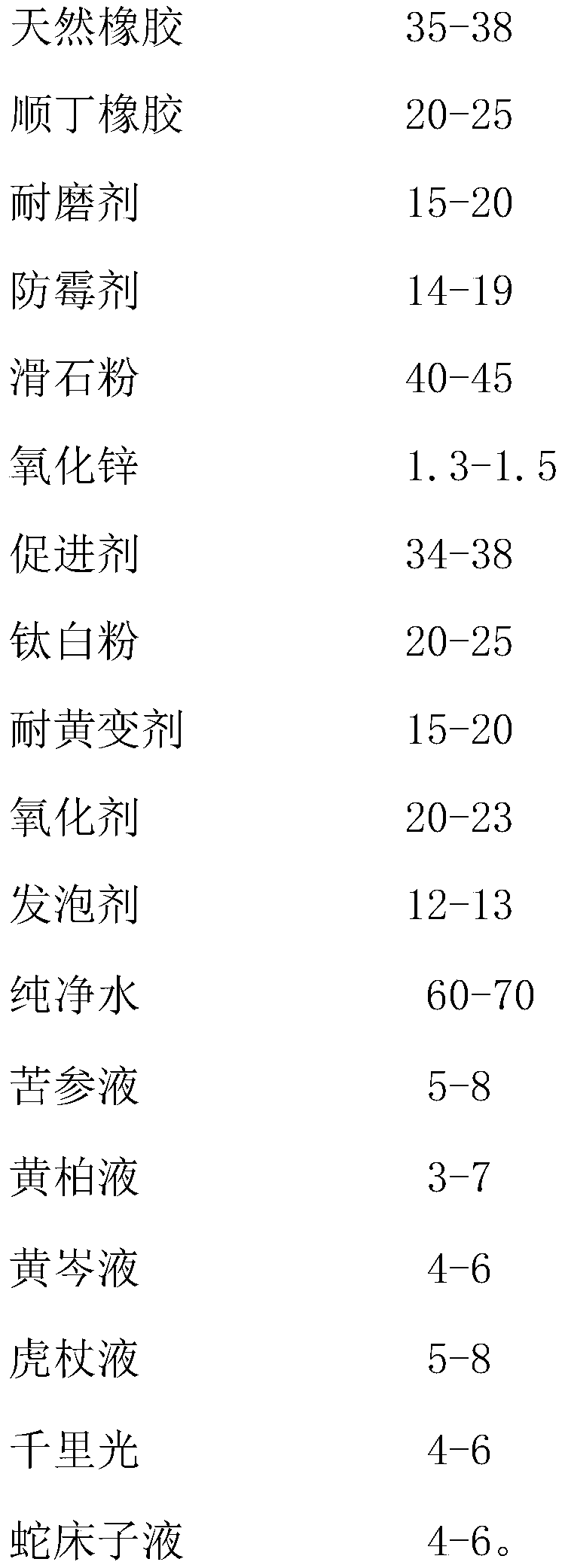

[0024] A kind of antibacterial foaming sole, comprises each raw material of following parts by weight:

[0025]

[0026] A preparation method for antibacterial foamed soles, comprising the following processing steps:

[0027] (1) Prepare raw materials: weigh each of the above-mentioned raw materials according to the proportioning ratio;

[0028] (2) Pretreatment main ingredients: mix natural rubber, butadiene rubber, wear-resistant agent, anti-fungal agent, talcum powder, zinc oxide, accelerator, titanium dioxide, anti-yellowing agent, oxidant, foaming agent, and stir evenly ;

[0029] (3) Banbury mixing: Put the main ingredients mixed evenly in step (2) into the internal mixer preheated to 180°C-185°C, add pure water, Sophora flavescens liquid, Cortex Phellodendri liquid, Scutellaria chinensis liquid, Polygonum cuspidatum liquid , Senecio, and Cnidium liquid, the speed of the internal mixer is controlled at 80-100r / min, and the mixer is mixed until it is in a molten stat...

Embodiment 2

[0038] A kind of antibacterial foaming shoe sole, comprises outsole and the midsole that is arranged on the outsole, and described outsole is made up of each raw material of following parts by weight:

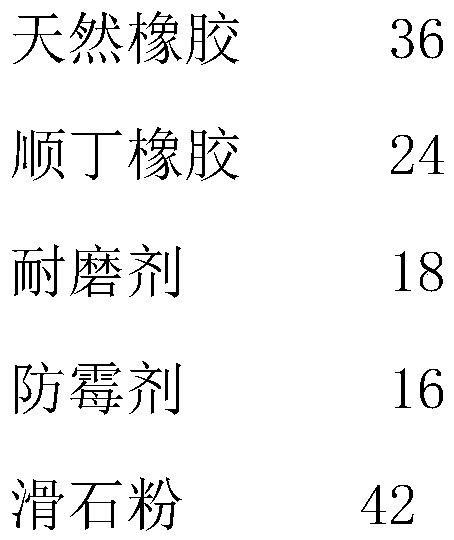

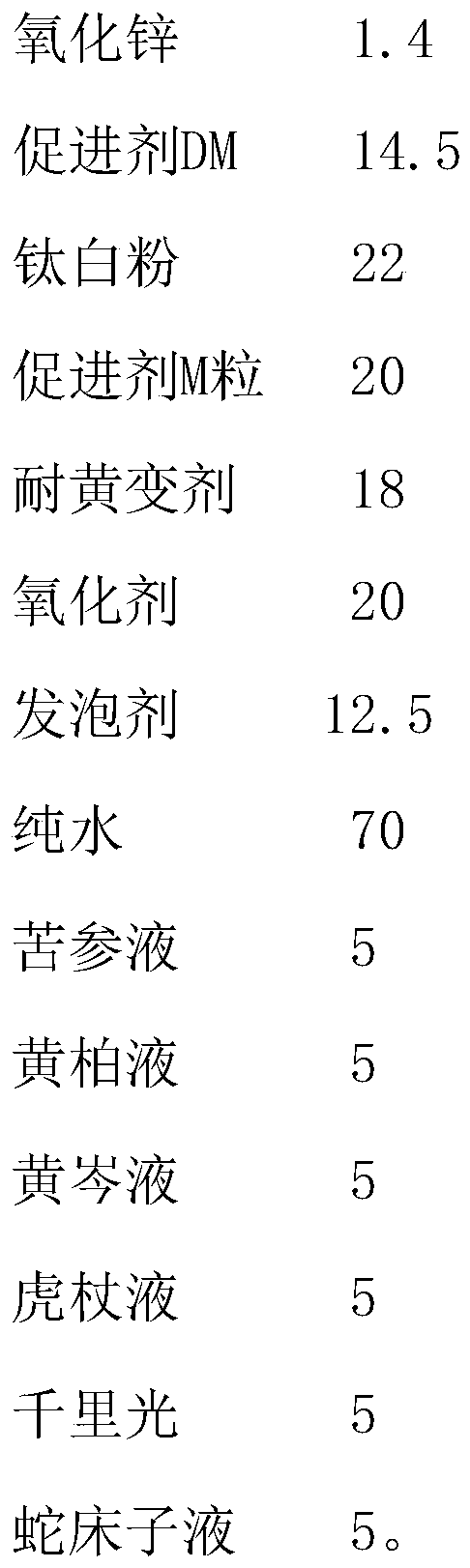

[0039] Natural rubber 36, butadiene rubber 24, wear-resistant agent 18, anti-mold agent 16, talcum powder 42, zinc oxide 1.4, accelerator DM14.5, titanium dioxide 22, accelerator M particles 20, anti-yellowing agent 18,

[0040] Oxidant 20, foaming agent 12.5, white pigment 10 parts by weight, pure water 70, Sophora flavescens liquid 5, Phellodendron cortex liquid 5, Scutellaria chinensis liquid 5, Polygonum cuspidatum liquid 5, Senecio 5, Cnidium fruit liquid 5.

[0041] The formula of the midsole is slightly different from that of the outsole. The pigment is yellow pigment, which is also 10 parts by weight, and the other formulas are consistent with the outsole.

[0042] Refer to Example 1 for the preparation method, and the difference from Example 1 is: after adding the raw ...

Embodiment 3

[0044] A kind of antibacterial foaming sole, is made up of each raw material of following parts by weight:

[0045] Natural rubber 38, butadiene rubber 25, wear-resistant agent 20, anti-mold agent 19, talc powder 45, zinc oxide 1.5, accelerator 38, titanium dioxide 25, anti-yellowing agent 20, oxidant 23, foaming agent 13, pure Water 70, Sophora flavescens liquid 8, Phellodendron chinensis liquid 7, Scutellaria chinensis liquid 6, Polygonum cuspidatum liquid 8, Senecio 4-6, Cnidium seed liquid 4-6.

[0046] Its preparation method is consistent with Example 1.

[0047] Wherein, the sole of the present invention can also be directly integrally formed with a multi-layer sole structure, and the color of each layer of sole can be designed according to the needs of customers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com