Highly matched and breathable insole and manufacturing method thereof

A manufacturing method and insole technology, applied to insoles, footwear, footwear, etc., can solve the problems of affecting service life, easy to break, poor air permeability, etc., and achieve the effects of preventing breakage, improving flexibility, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

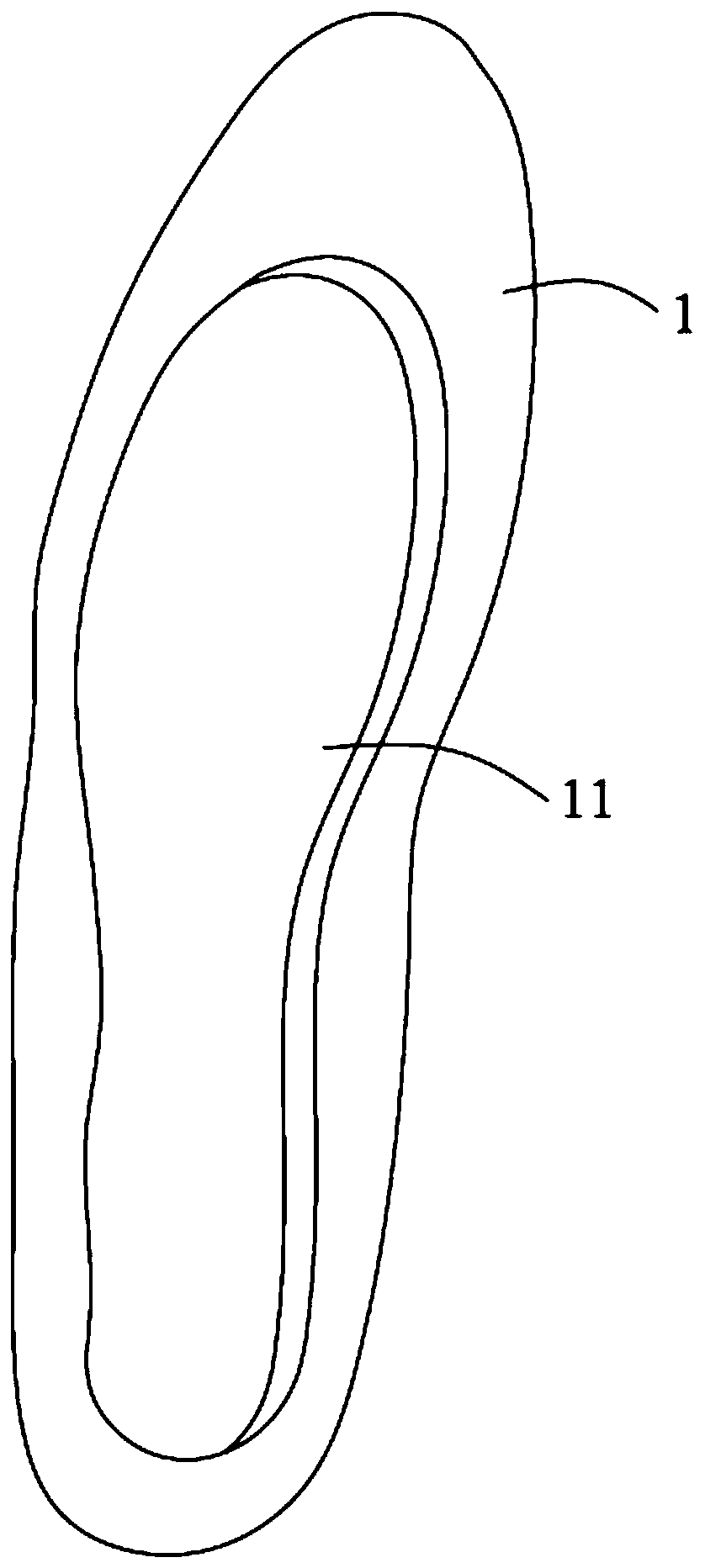

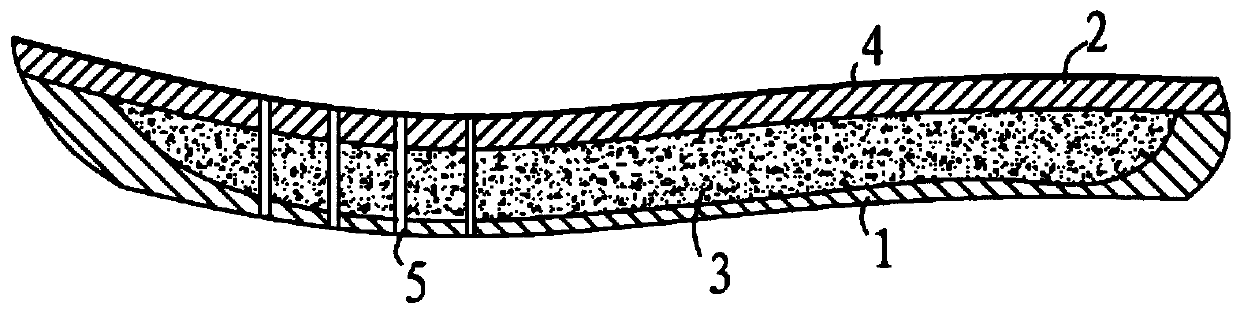

[0034] refer to figure 1 and figure 2 . A highly fitting and breathable insole, comprising a shoe mold layer 1, an upper mold layer 2 and a filling layer 3, the shoe mold layer 1 is provided with an accommodating cavity 11, the filling layer 3 is arranged at the accommodating cavity 11, the shoe mold layer 1 The edge of the shoe is fixed to the edge of the upper mold layer 2, the filling layer 3 is located between the shoe mold layer 1 and the upper mold layer 2, and the shapes of the filling layer 3 and the upper mold layer 2 are consistent with the shape of the sole of the user. In actual use, both the shoe mold layer 1 and the upper mold layer 2 can be integrally injection-molded with plastic; the shoe mold layer 1 is provided with an accommodating cavity 11 to facilitate the placement and filling of the filling layer 3 .

[0035] The filling layer 3 includes cork chips and hot melt adhesive, the weight ratio of cork chips to hot melt adhesive is 1:2-4; the particle size...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, and the difference is that a method for making a highly consistent and breathable insole is provided, including the following steps:

[0056] S01', uniformly mixing cork chips and hot melt adhesive according to the weight ratio of 1:2 to 4, and spreading them into a thickness corresponding to the accommodation cavity;

[0057] S02'. After heating the above materials, the heating temperature is 50-100°C, so that the hot melt glue melts and infiltrates between the cork chips, and forms a shape that matches the curvature of the soles of the human feet. Partially cut to obtain the insole; the molding is pressed and formed by a molding die, and can be punched and cut;

[0058] S03', put the above-mentioned insole into the accommodating cavity on the shoe mold layer;

[0059] S04', fixing the upper mold layer and the shoe mold layer;

[0060] S05', heating the fixed upper mold layer and the shoe mold layer again, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com