A kind of high moisturizing elastic base wet-process spunlace mask base fabric and its production process

An elastic base and base fabric technology, applied in the field of medical beauty, can solve the problems of low transfer rate of nutrient solution, small elasticity, heavy environmental pollution, etc., to ensure skin fit, reduce energy consumption, and increase liquid retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

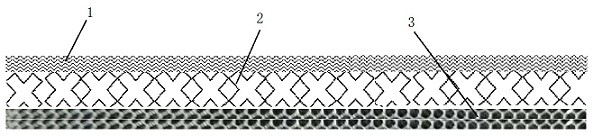

[0030] Such as figure 1 A high moisturizing elastic base wet-process spunlace mask base cloth is shown, the mask base cloth is composed of upper, middle and lower layers, wherein the upper layer is kapok / PP suction and release control layer 1, and the middle layer is wood pulp / sticky A high moisture-retaining filling layer 2 composed of glue, and a lower layer of nylon elastic base cloth lining 3.

[0031] In this example, in the kapok / PP suction and release control layer 1, the kapok fiber mass fraction is 30-60%, the PP fiber mass fraction is 40-70%, and the prepared kapok / PP suction and release control layer has a density of 10% -20g / m 2 ;

[0032] In this example, the kapok / PP absorption and release control layer 1, the length of kapok fiber and PP fiber is 8-12mm, the fineness of kapok fiber is 0.8-1.5D, the fineness of kapok fiber is 0.8-1.5D, and the fineness of PP fiber is 0.8-1.5D. 1.5-2D;

[0033] In this example, in the wood pulp / viscose high moisturizing layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com