Steel strip pipe cutting machine with grinding and deslagging functions

A steel strip tube and cutting machine technology, which is applied in the direction of manufacturing tools, maintenance and safety accessories, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

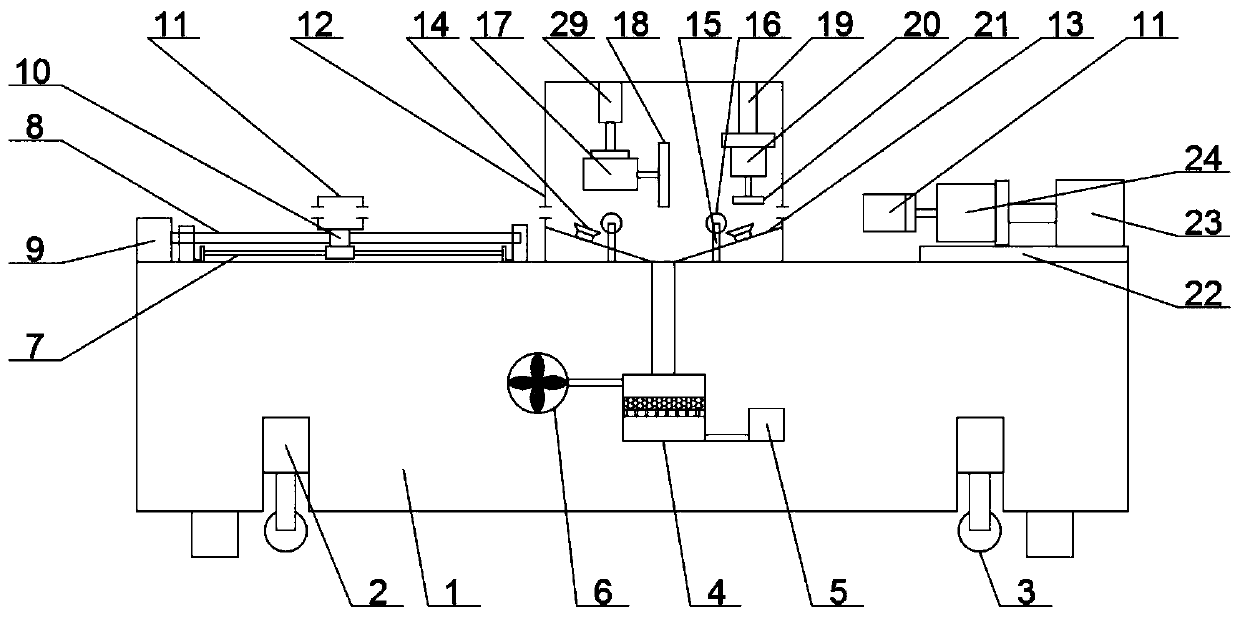

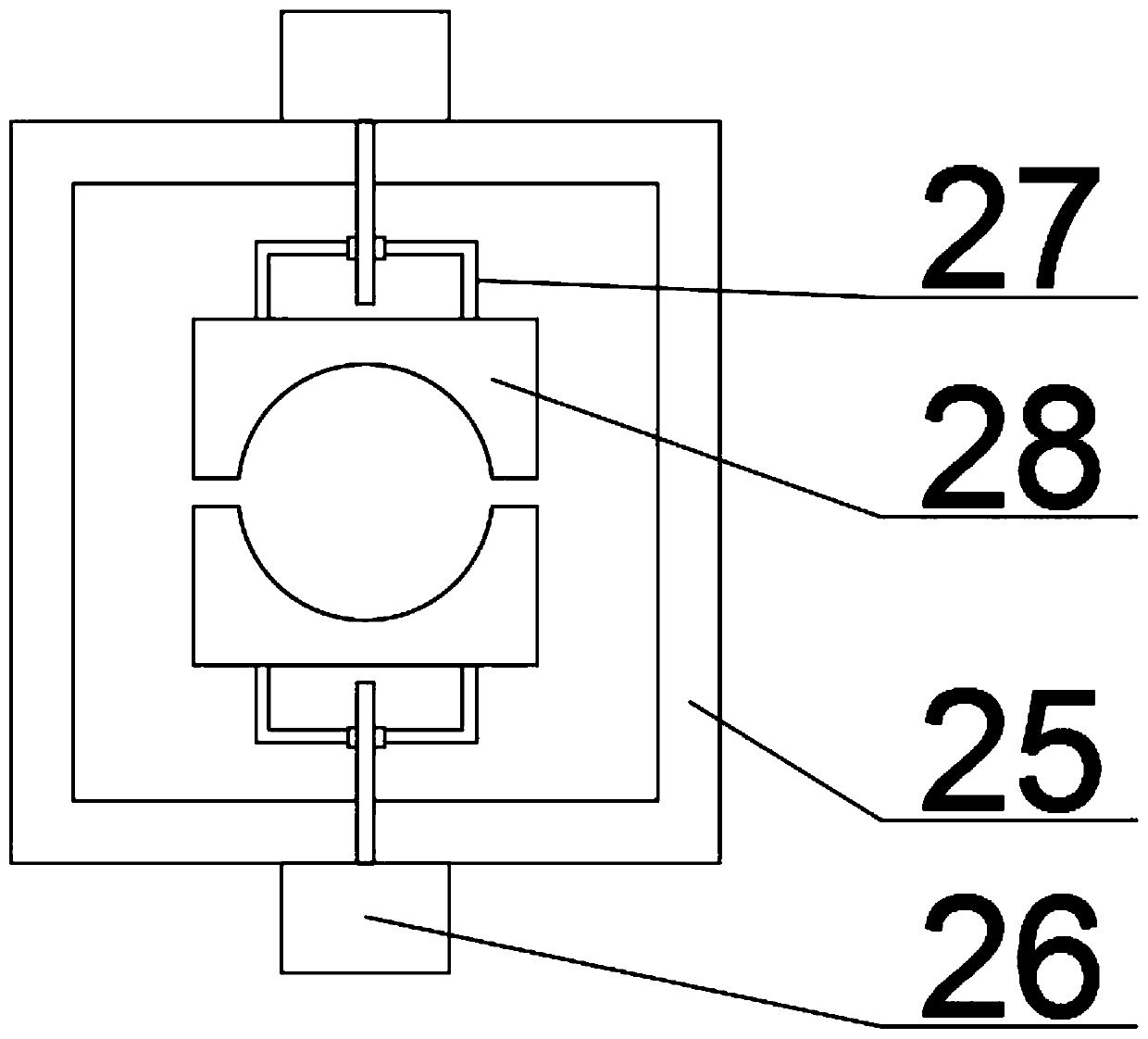

[0022]A steel pipe cutting machine with grinding and slag removal functions, comprising a base 1, the bottom of the base 1 is provided with legs, the bottom of the base 1 is also provided with four grooves, and the center of the bottom surface of the four grooves is The connecting lines form a rectangle, the groove is provided with a lifting hydraulic cylinder 2, the bottom end of the telescopic rod of the lifting hydraulic cylinder 2 is provided with a universal wheel 3, and the base 1 is provided with a waste residue box 4, and the waste residue box 4. A sieve is provided on an inner slope. The rear side of the sieve is higher than the front side of the sieve and the front side of the waste slag box is provided with a slag discharge box door. The bottom surface of the sieve is provided with a vibrating motor. A delivery pump 5 and a fan 6 are provided, the fan 6 communicates with the top end of one side of the waste residue box 4 through a ventilation pipe, the input end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com