Automatic shearing system, automatic shearing method and automatic production line for steel grid plate as well as manufacturing method

A steel grating and shearing head technology, applied in the field of steel grating automatic shearing system, can solve the problems of lack of automatic feeding mechanism, low production efficiency, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

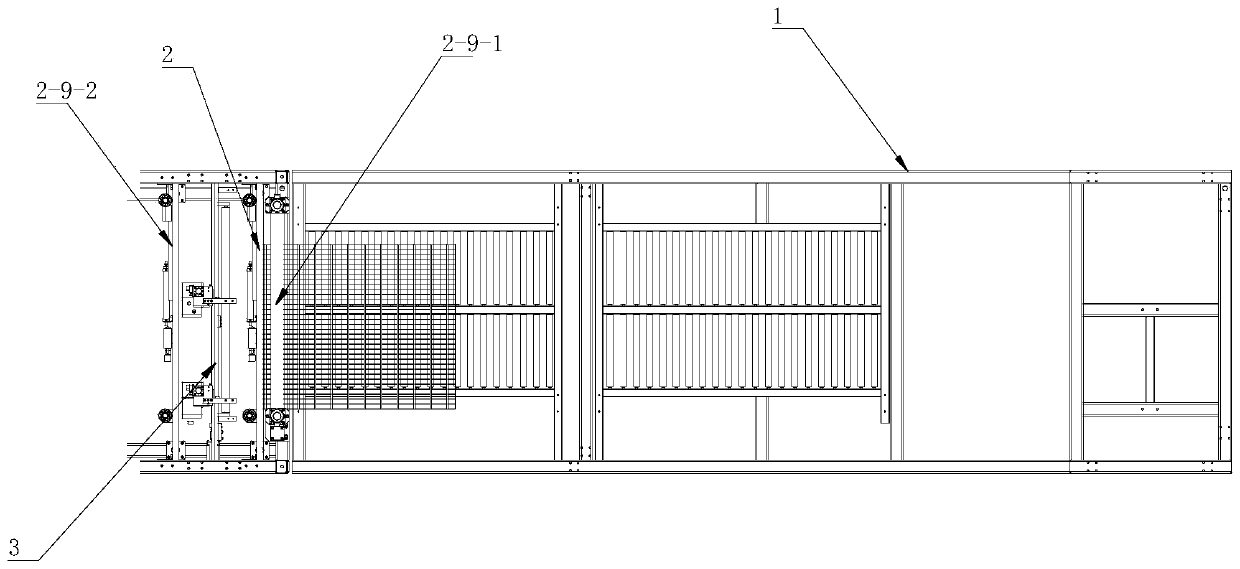

[0098] An automatic steel grating shearing system, comprising a base 1 on which a feeding mechanism 2 and a shearing device 3 are installed,

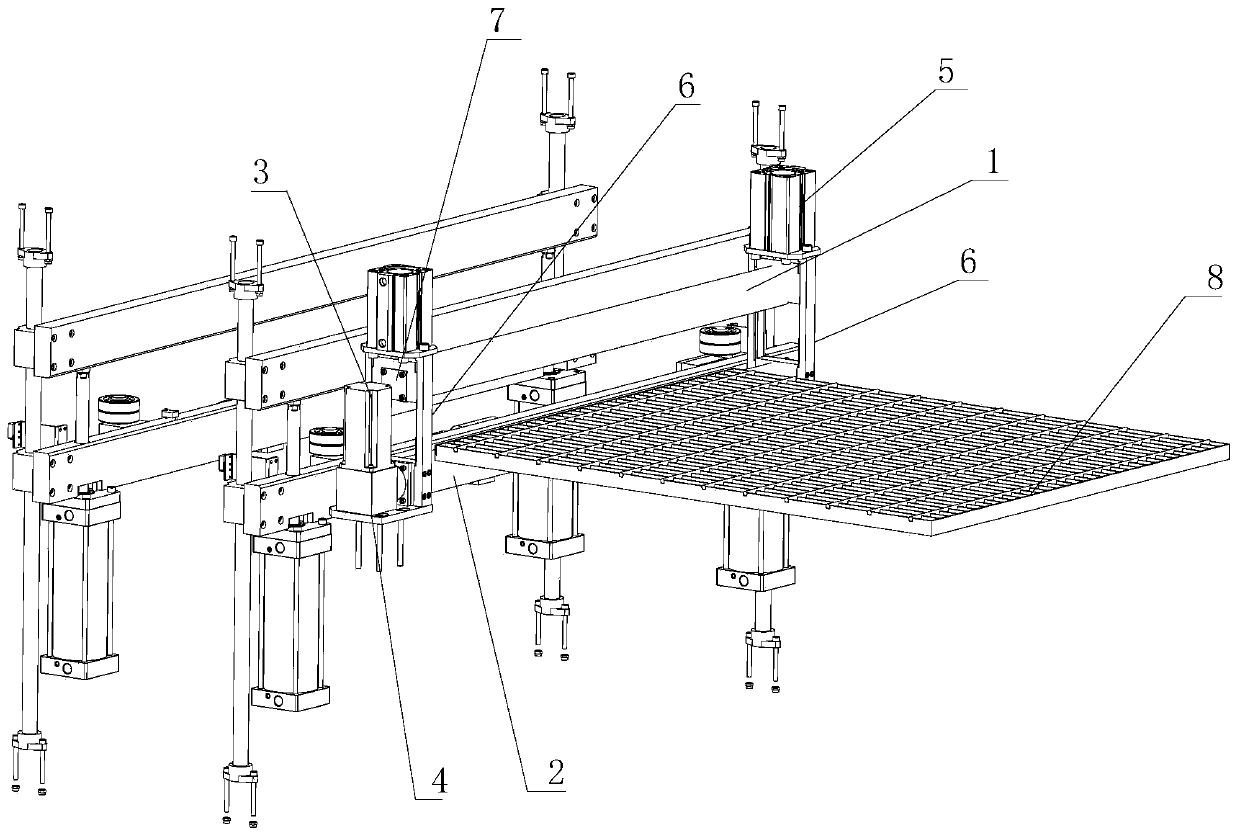

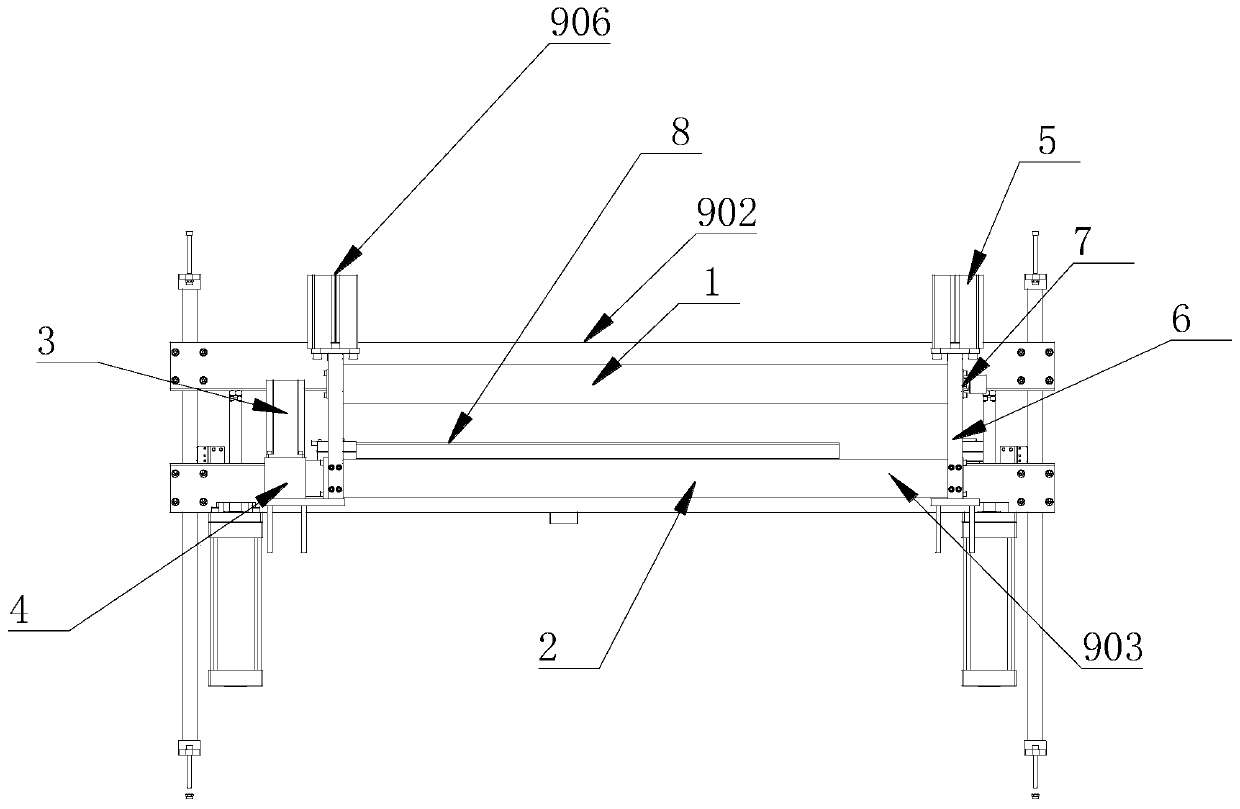

[0099] Among them, refer to figure 2 and image 3 As shown, the feeding mechanism 2 includes an upper drum 2-1 and a lower drum 2-2. The lower drum 2-2 is driven to rotate by the first power device, and the upper drum 2-1 is arranged on the lower drum 2-2. 2. The upper part is driven by the second power device to move up and down to loosen or compress the workpiece 2-8 between the upper roller 2-1 and the lower roller 2-2.

[0100] continue to refer figure 2 and image 3 As shown, the first power device includes a drive motor 2-3 and a reducer 2-4, and the drive motor is connected to the lower drum 2-2 through the reducer 2-4 to drive the lower drum 2-2 rotate.

[0101] continue to refer figure 2 and image 3 As shown, the second power device includes a pressing cylinder 2-5, and the pressing cylinder 2-5 is connected to the u...

Embodiment 2

[0127] refer to Figure 10 As shown, an automatic steel grating production line includes the steel grating automatic shearing system as described in Embodiment 1, and an edge-sealing welding mechanism 4 is also installed on the base 1, and the edge-sealing welding mechanism 4 includes an edge sealing welding clamping mechanism 5 for fixing steel grating workpieces;

[0128] Preferably, on the base 1 , a workpiece transmission mechanism 5 is installed between the edge sealing welding mechanism 4 and the shearing device 3 .

[0129] In the specific implementation, after the steel grating workpiece (the workpiece that has been welded with flat steel) is cut, it enters the edge-sealing welding mechanism for edge-sealing welding, and finally processed into a finished steel grating. The perfectly coordinated production line has the advantages of high processing quality, high efficiency, and low cost for line replacement.

Embodiment 3

[0131] Based on the automatic steel grating shearing system described in Embodiment 1, this embodiment provides an automatic steel grating shearing method, including the following steps:

[0132] Step 1: Feeding: the steel grating workpiece enters between the upper roller and the lower roller, the pressing cylinder drives the upper roller to press the steel grating workpiece tightly, and the lower roller rotates to realize feeding;

[0133] Step 2: Measuring the transportation distance: use the travel sensor device to measure the transportation distance of the steel grating workpiece;

[0134] Step 3: Clamping: Determine whether the steel grating workpiece has entered the area where the clamping mechanism is located by the distance detected by the stroke sensor device. After entering the area, it is controlled by the controller:

[0135] The lower drum stops rotating and feeding,

[0136] The upper compression bar presses down to fit the lower compression bar to limit the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com