Stainless steel pipe holing device

A drilling equipment, stainless steel technology, applied in the direction of drilling / drilling equipment, metal processing equipment, boring / drilling, etc., can solve the problems of large debris, laborious collection, working environment pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

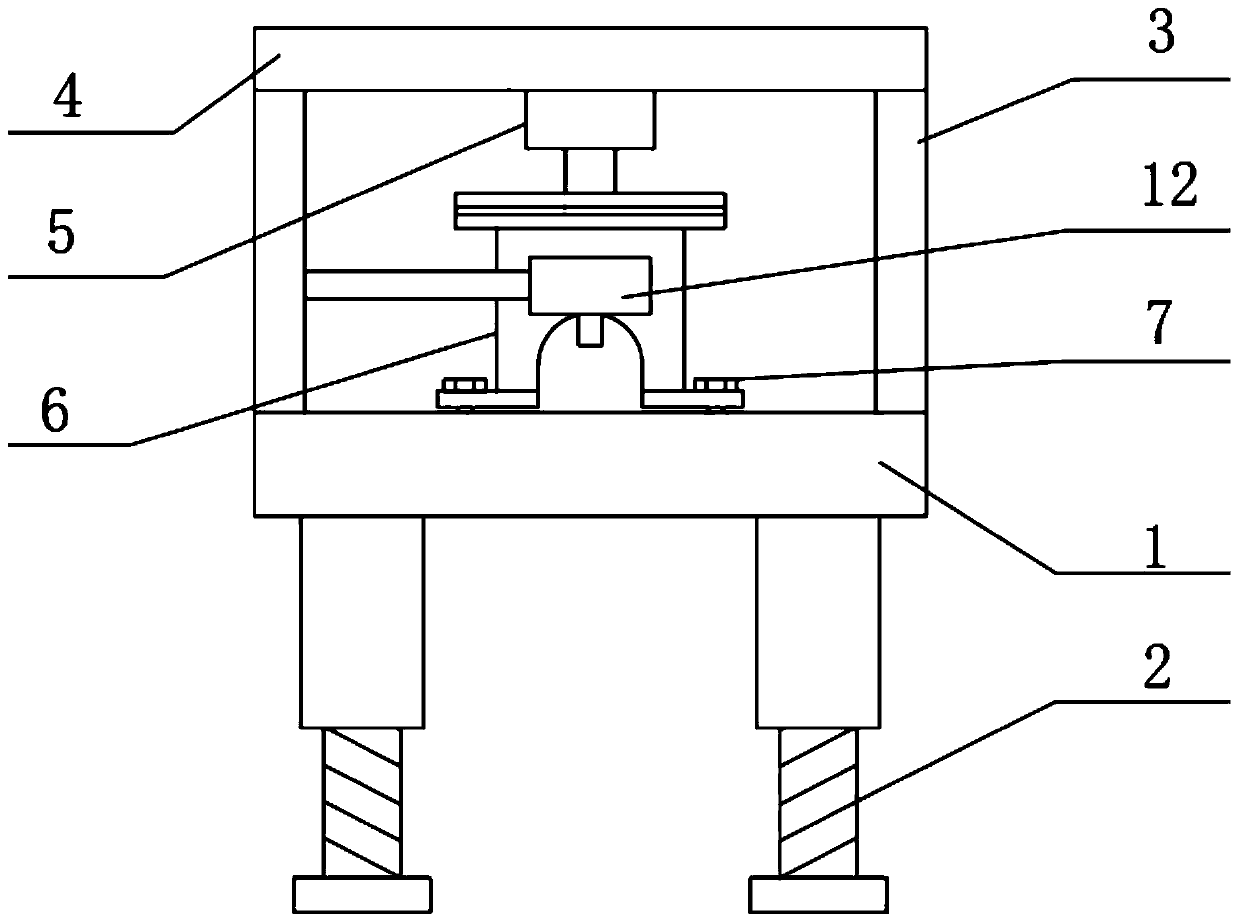

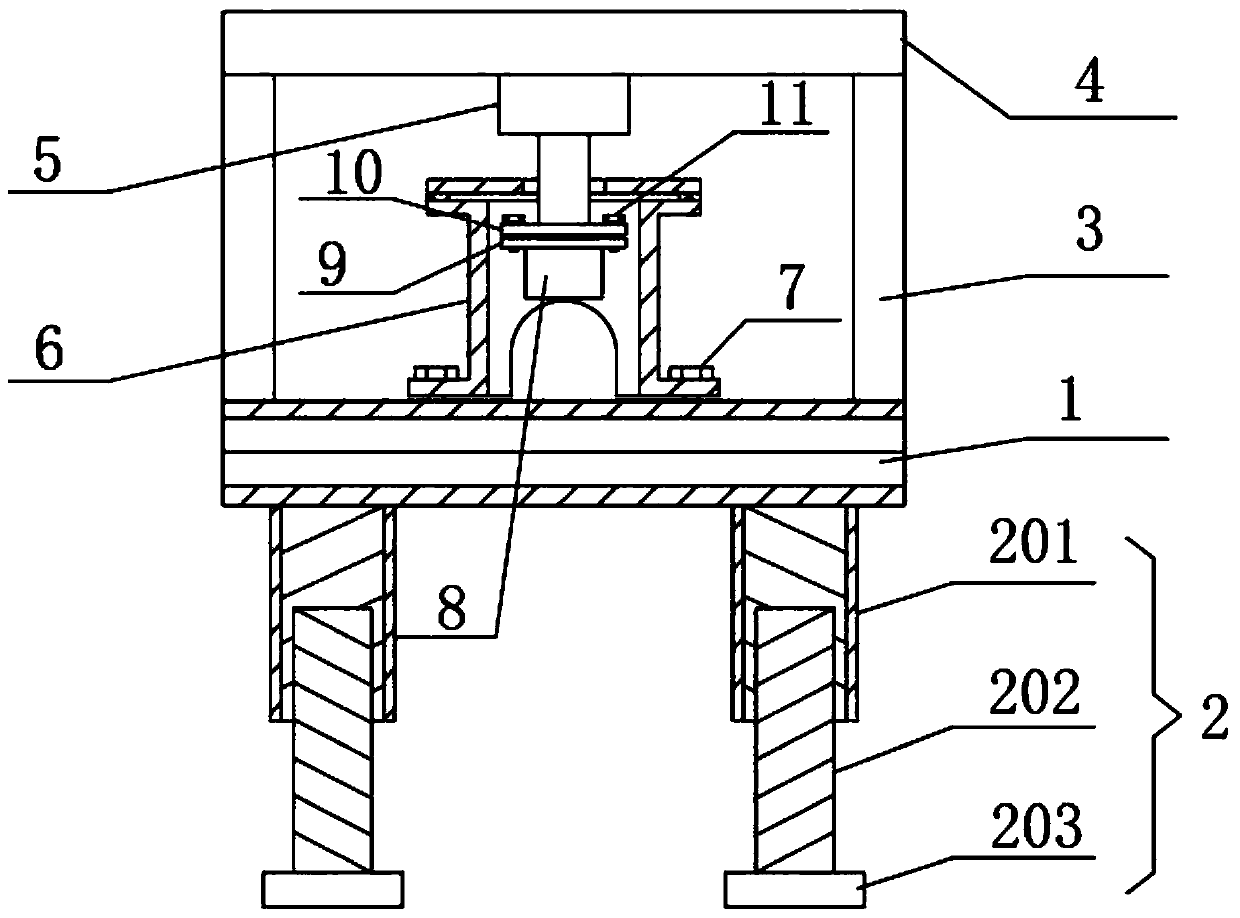

[0026] like Figure 1-6 As shown, a stainless steel pipe fitting drilling equipment includes a support body 1, the lower end of the support body 1 is connected with a support leg 2, the upper end of the support body 1 is connected with the same top plate 4 through two side plates 3, and the lower end surface of the top plate 4 A hydraulic telescopic rod 5 is connected, and a steel pipe limiting device 6 is arranged directly below the hydraulic telescopic rod 5, and the steel pipe limiting device 6 is located between the two side plates 3;

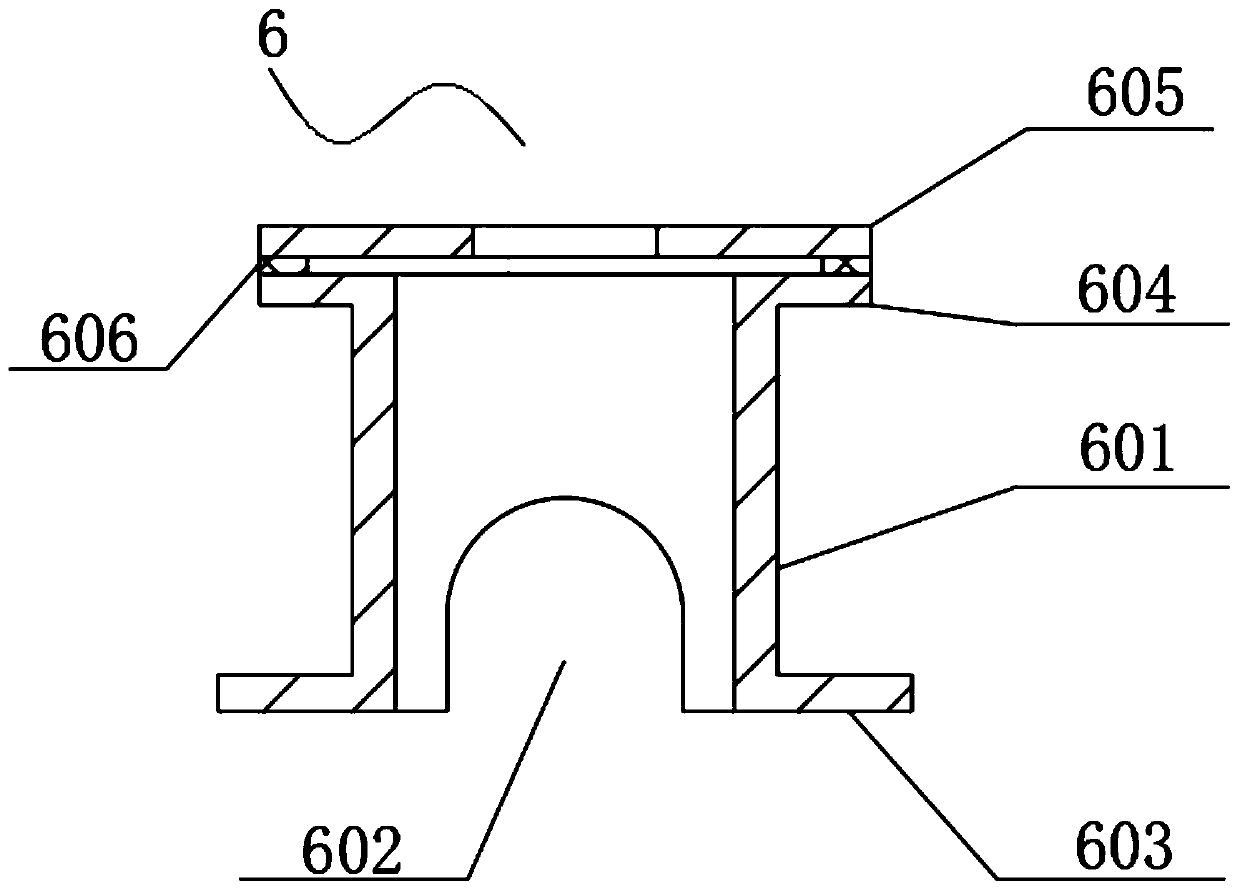

[0027] The steel pipe limiting device 6 includes a limiting sleeve 601, the lower end of the limiting sleeve 601 is provided with a limiting hole 602, and the lower end of the limiting sleeve 601 is provided with a lower flange 603, which is movable in the through hole provided on the lower flange 603. The first locking screw 7 is plugged in, and the first locking screw 7 is threadedly connected with the threaded hole provided on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com