Processing device of nonwoven fabric

A processing device, non-woven fabric technology, applied in the direction of the device for coating liquid on the surface, pre-treatment surface, coating, etc., to achieve the effect of high elongation elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

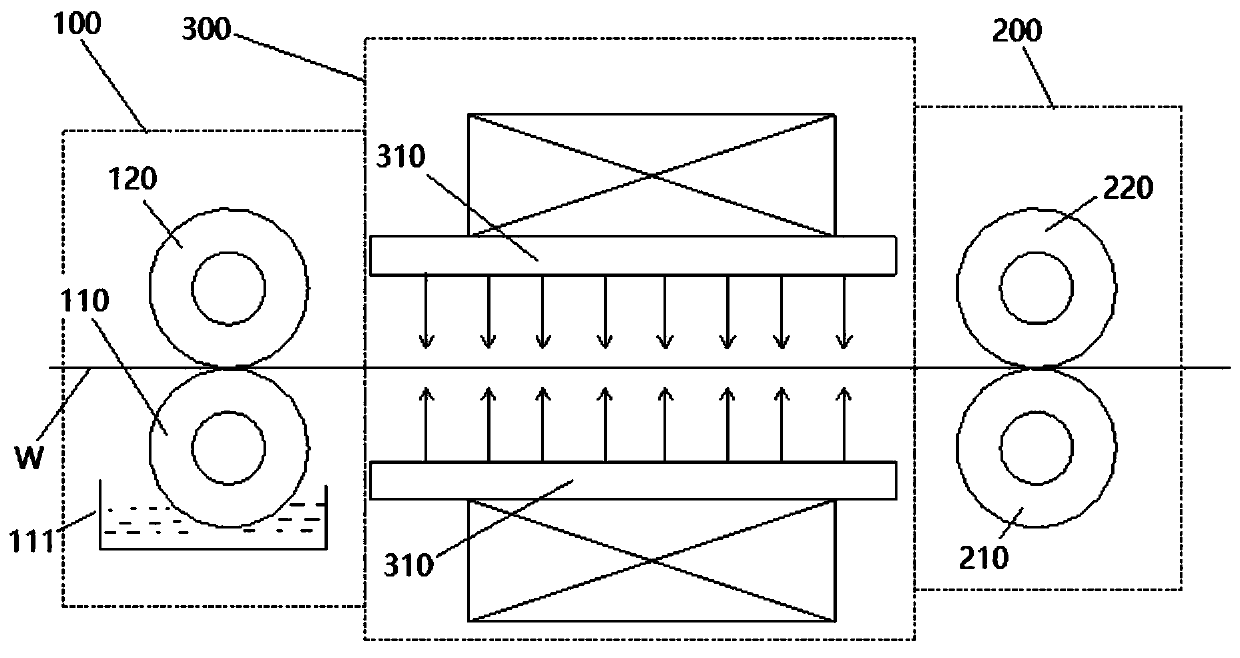

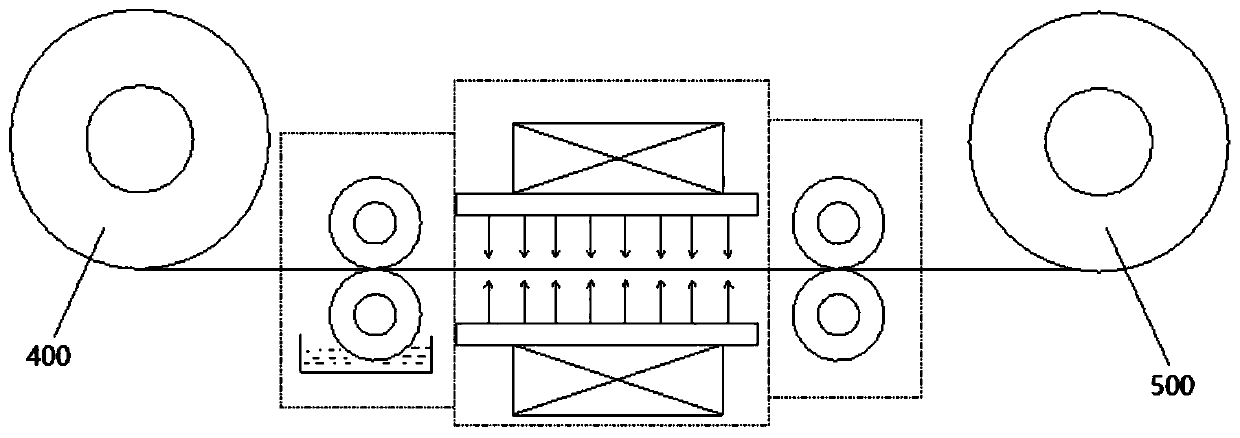

[0036] See figure 1, the present invention provides a non-woven fabric processing device comprising: a gluing mechanism 100, a sizing mechanism 200 and a wind pressure baking mechanism 300; , the spacing between the gluing roller 110 and the pressure roller 120 roll wall is suitable for the thickness of the nonwoven fabric; As shown in the figure): a glue groove 111 is arranged below the glue-coating roller 110, and the minimum distance between the wall of the glue-coating roller 110 and the bottom of the glue groove 111 is less than the groove depth of the glue groove 111; The sizing mechanism 200 includes: a driving roller 210 and a driven roller 220 arranged in parallel to the roller shaft; the distance between the driving roller 210 and the driven roller 220 is adapted to the thickness of the nonwoven fabric; the driving roller The roller shaft of 210 is parallel with the roller shaft of described gluing roller 110; Described active roller 210 is provided with the second ...

Embodiment 2

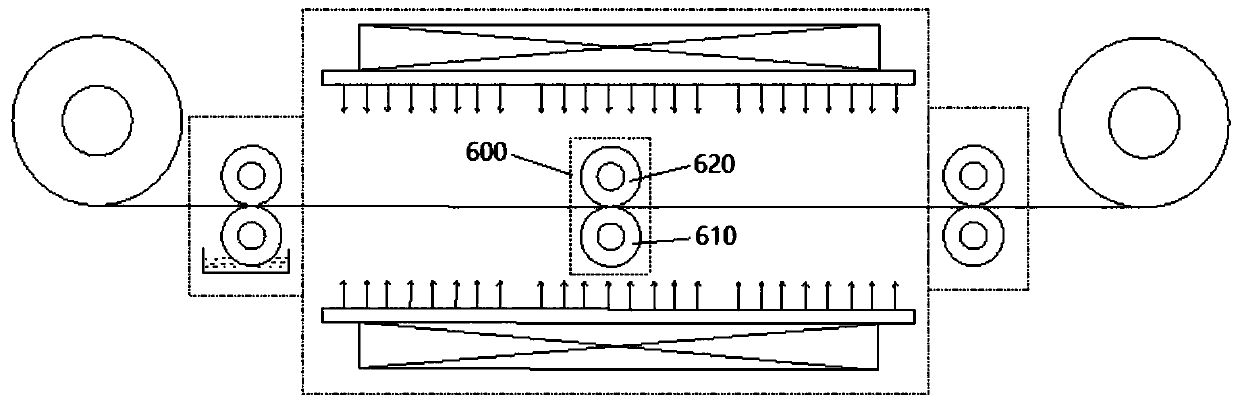

[0046] Such as image 3 As shown, in this embodiment, on the basis of the above-mentioned embodiments, a traction mechanism 600 is also provided between the gluing mechanism and the shaping mechanism; the traction mechanism 600 includes: a driving traction roller 610 and a driven traction roller 620; The distance between the active traction roller and the wall of the driven traction roller is adapted to the thickness of the nonwoven fabric; the active traction roller is provided with a fourth drive device; the speed of the active traction roller traction nonwoven fabric is between the set Between the drawing speed of the non-woven fabric drawn by the gluing mechanism and the sizing mechanism.

[0047] Preferably, see Figure 4 , in one of the preferred technical solutions of the present application, it also includes a casing G; the gluing mechanism, traction mechanism, shaping mechanism and air pressure baking mechanism are sealed in the casing.

[0048] Preferably, as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com