Waterflow-driven water outlet device

A technology of water flow drive and water outlet device, which is applied in the direction of spraying device, spraying device, etc., which can solve the problems of easy slanting of water spray, inability to move the descaling plate normally, and inability to clean scale, etc., to achieve uniform distribution of water spray and excellent shower experience , good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

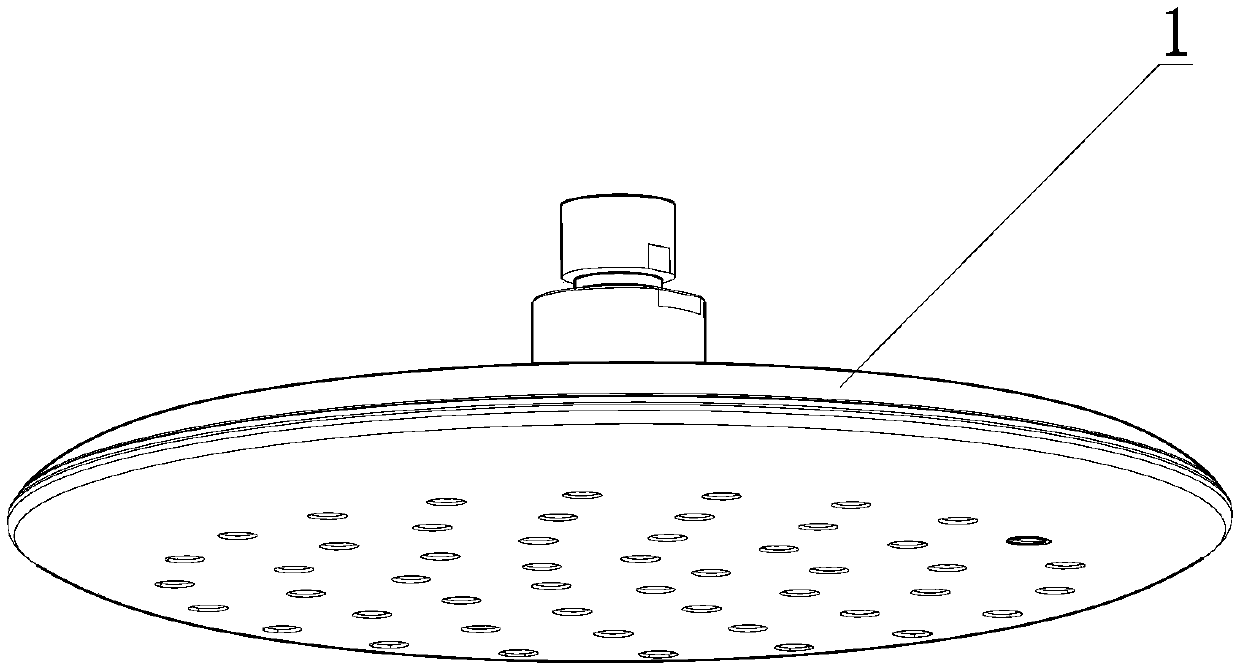

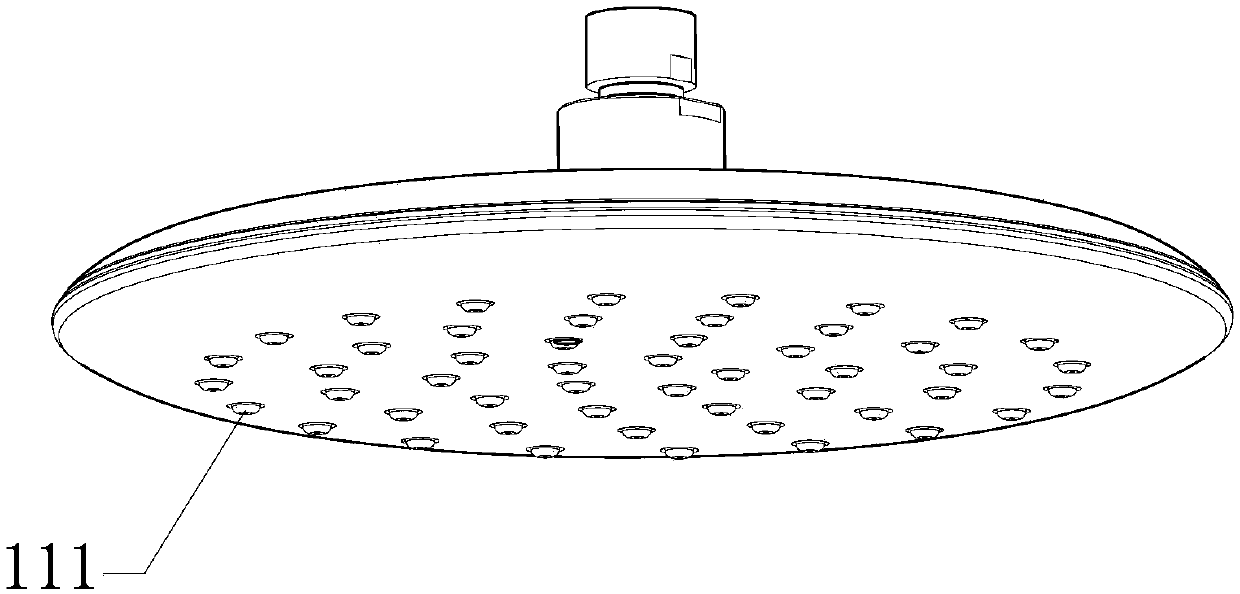

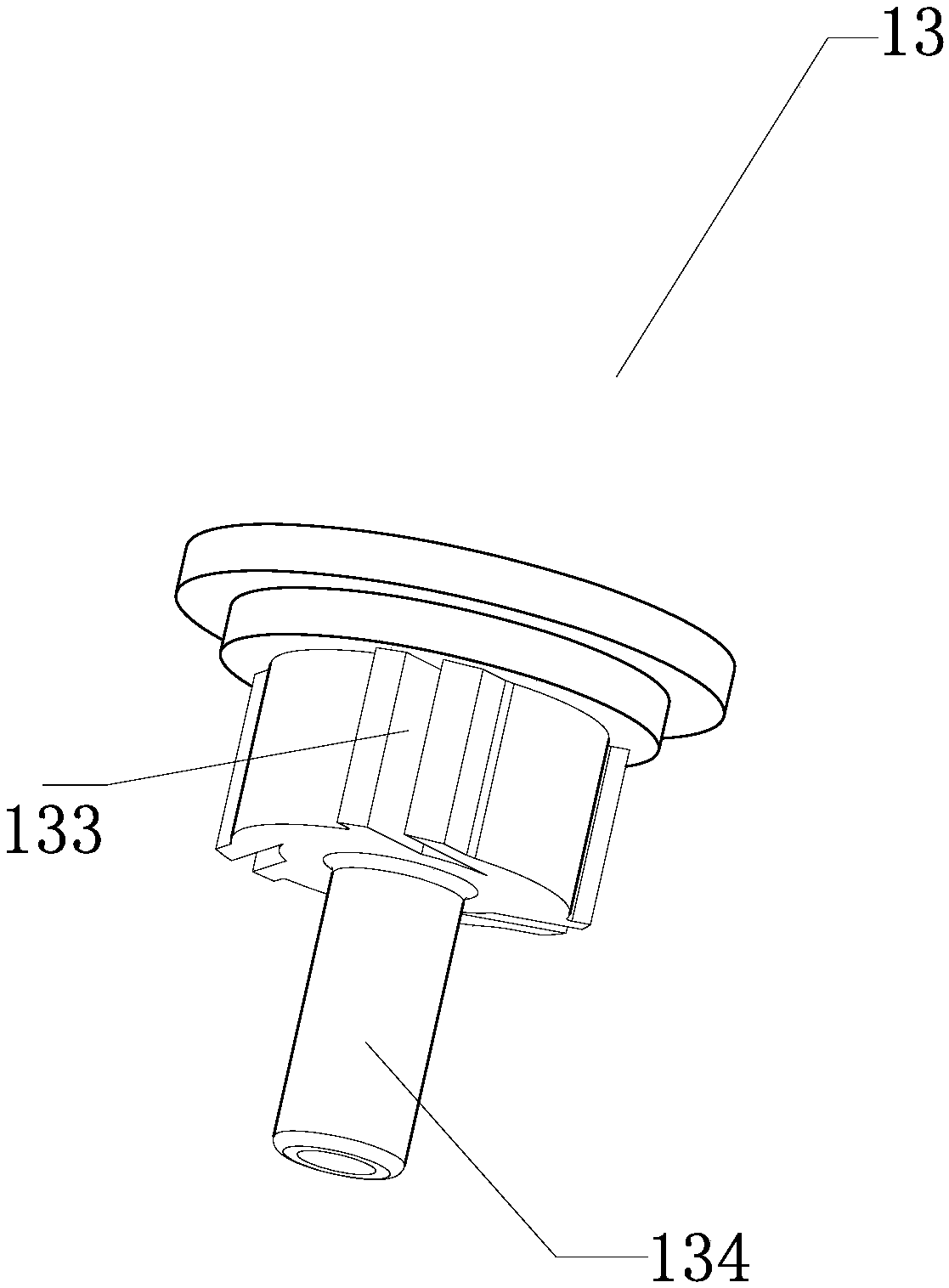

[0031] refer to Figure 1-7 , a water outlet device driven by water flow. In this embodiment, the water outlet device is preferably but not limited to a shower. The shower comprises: a body 1 , a descaling needle plate 2 placed in a cover assembly 11 , and a rotating member 3 driven by water flow to rotate around the axial direction; the cover assembly 11 is located inside the body 1 as a whole. In this embodiment, the oscillating plate is preferably designed as the descaling needle plate 2. In fact, it can also be designed as a simple oscillating plate without descaling effect. Compared with the descaling needle plate, the simple oscillating plate does not have descaling. function, but it also has the effect of changing the water splash.

[0032] The descaling needle plate 2 and the face cover assembly 11 are arranged coaxially and interlockingly along the axial direction, and the descaling needle plate 2 has a plurality of thimbles 21 as spoilers, and the water outlet hole ...

Embodiment 2

[0045] refer to Figure 8 , the difference between this embodiment and embodiment 1 is: in embodiment 1, the descaling needle plate 2 and the face cover assembly 11 are coaxially arranged, and in embodiment 2, the descaling needle plate 2 and the face cover assembly 11 are not coaxially placed , the same technical effect of the present invention can be realized. The structure of other parts is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com