Test device for simulating marine environment dynamic and static combined concrete loading

A technology of combined loading and marine environment, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the durability erosion mechanism, process and results of concrete structures that do not match the actual situation, lack of concrete structures Durability test methods, accelerated durability degradation of concrete structures and other issues, to achieve the effect of simple structure, high degree of automation, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

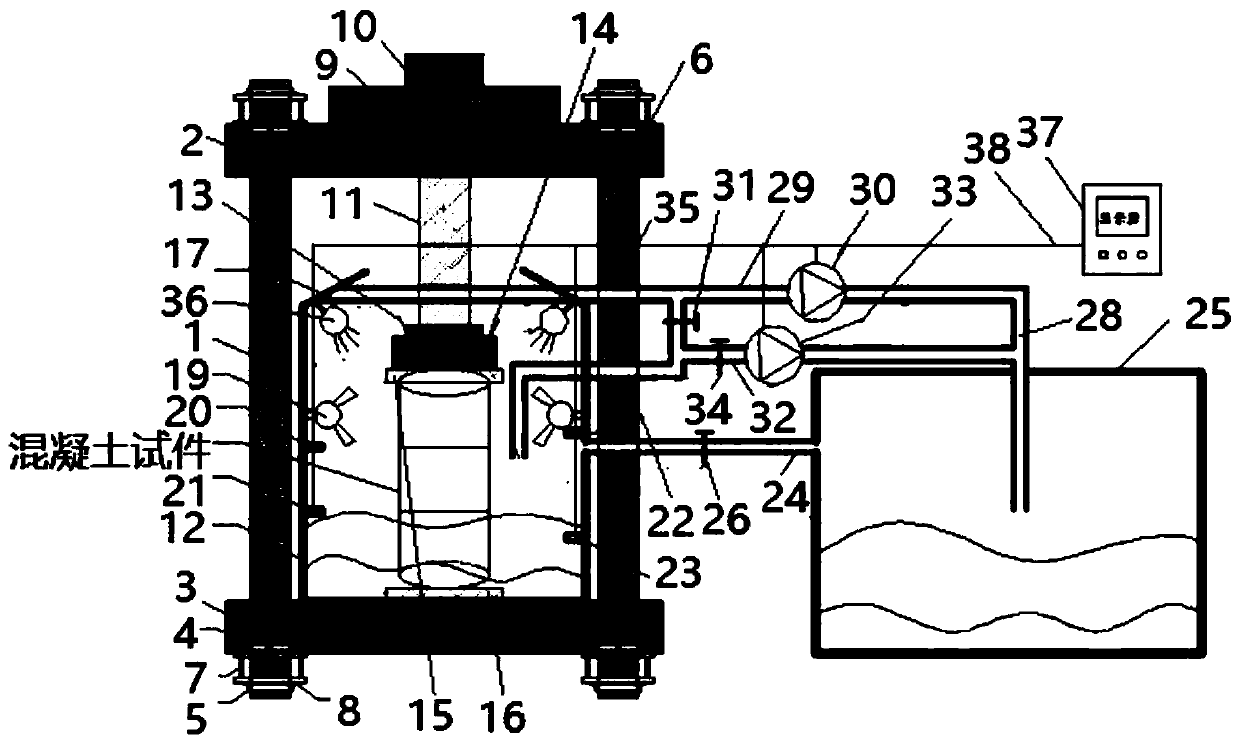

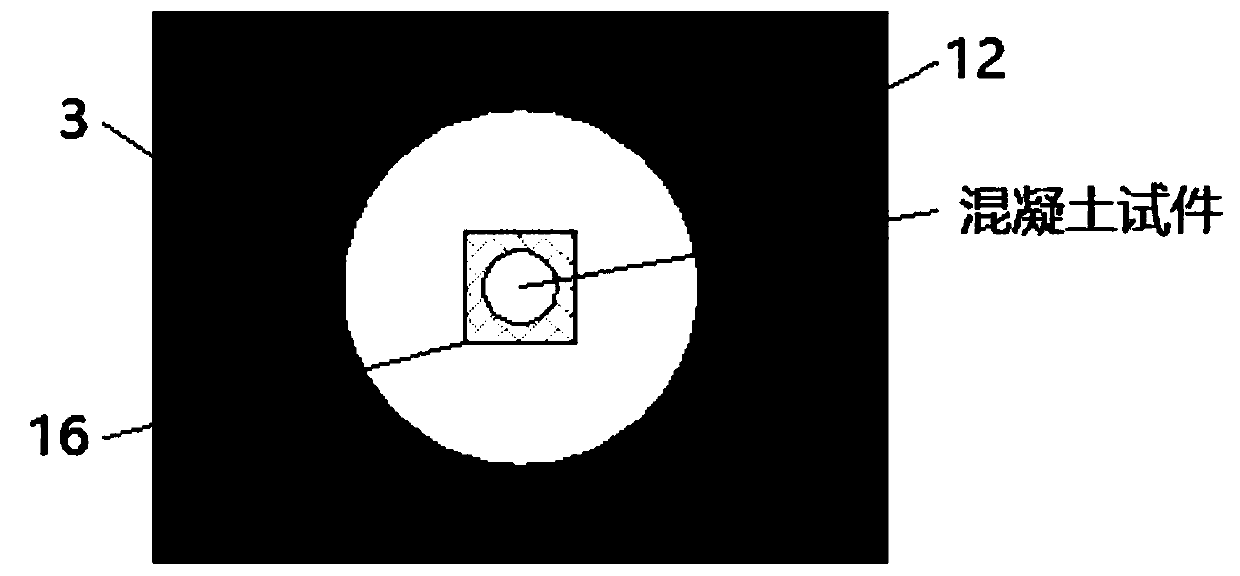

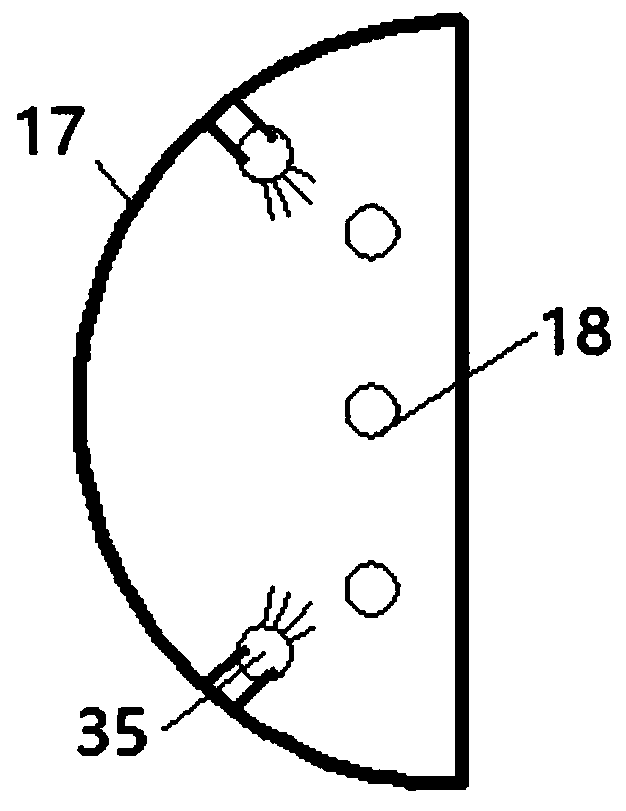

[0021] The main structure of the experimental device for simulating marine environment dynamic and static joint loading concrete involved in this embodiment includes a column 1, an upper horizontal plate 2, a lower horizontal plate 3, bolts 4, screw caps 5, a support frame 7, a backing plate 8, and a force transmission plate 9. Piston 10, screw 11, test box 12, pressure sensor 13, jack 14, upper plate 15, lower plate 16, test box cover 17, test box vent 18, ceiling fan 19, upper water level sensor 20, lower water level sensor 21 , temperature and humidity sensor 22, temperature sensor 23, connecting water pipe 24, liquid storage tank 25, communication valve 26, liquid storage tank vent hole 27, pipe frame 28, water inlet pump 30, water inlet valve 31, water outlet pipe 32, water outlet pump 33. Outlet valve 34, spray water pipe 35, spray head 36, control box 37 and wire 38; four columns 1, upper horizontal plate 2 and lower horizontal plate 3 are connected to form frame 6 by bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com