Experiment platform of non-contact measurement axial-symmetric fluid thin film morphology

A fluid thin film, non-contact technology, applied in the direction of fluid dynamics test, measuring device, machine/structural component test, etc., can solve the problems of detection element disturbance, short service life, original flow field affecting measurement accuracy, etc., to achieve The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

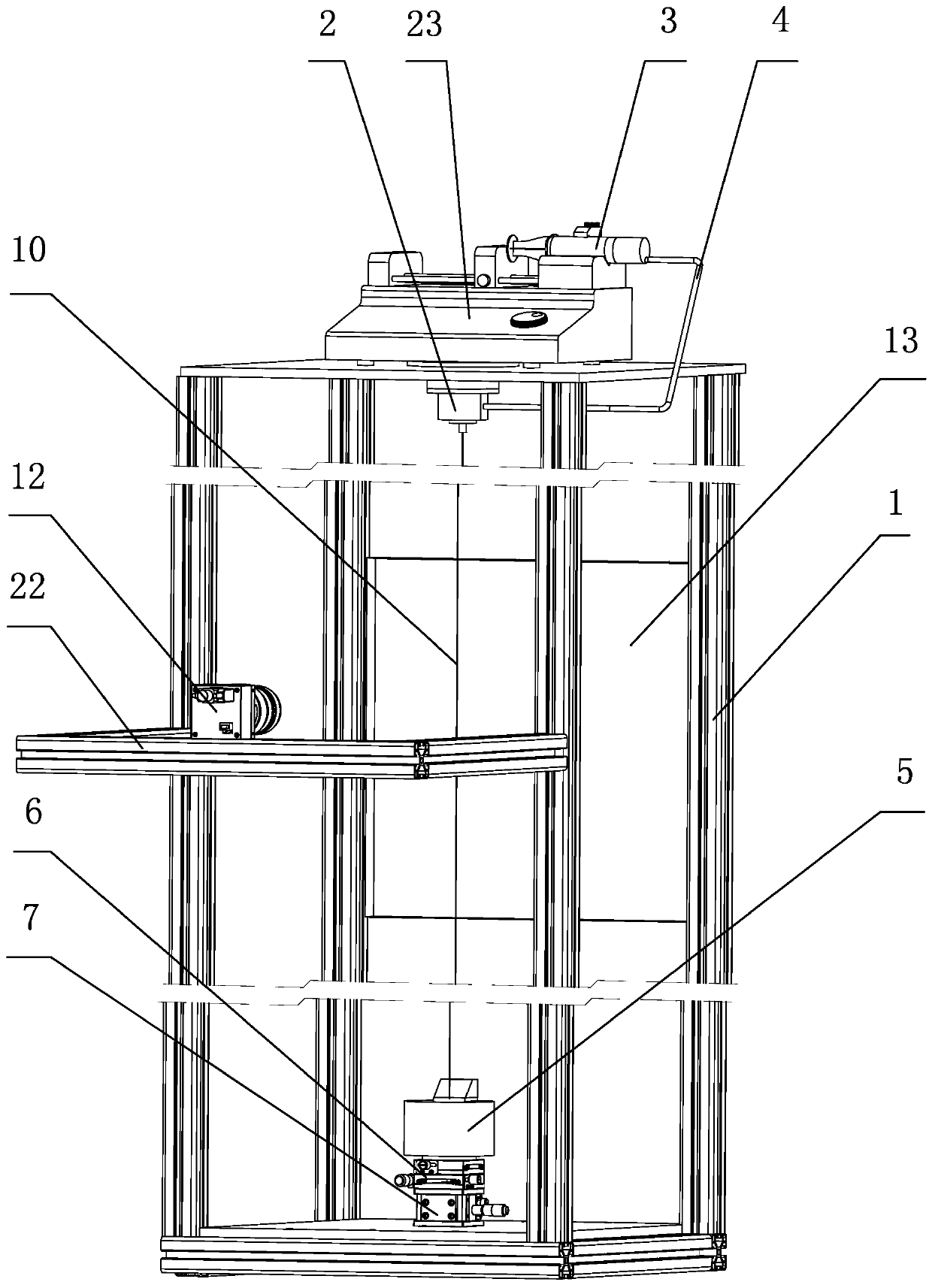

[0027] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

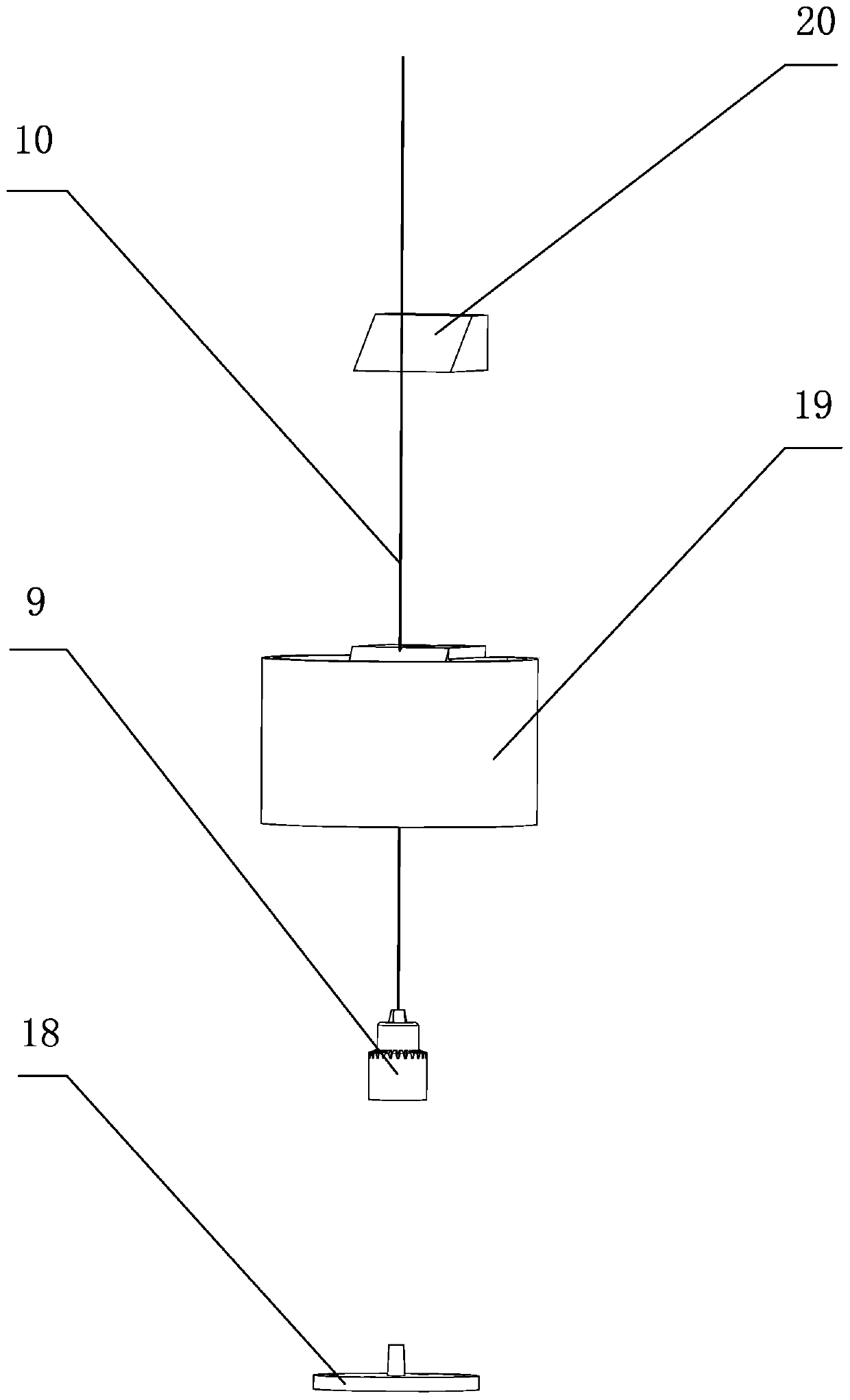

[0028] The experimental platform for non-contact measurement of axisymmetric fluid film form of the present invention includes a fluid flow control device, a fluid film preparation device, an image acquisition device and a fluid collection device based on a frame 1, and the frame 1 is a vertical square frame , the upper port of the frame 1 is provided with a top platen, the lower port is provided with a bottom platen, and the front side of the frame 1 is provided with a lifting frame 22 that can move up and down, such as figure 1 shown.

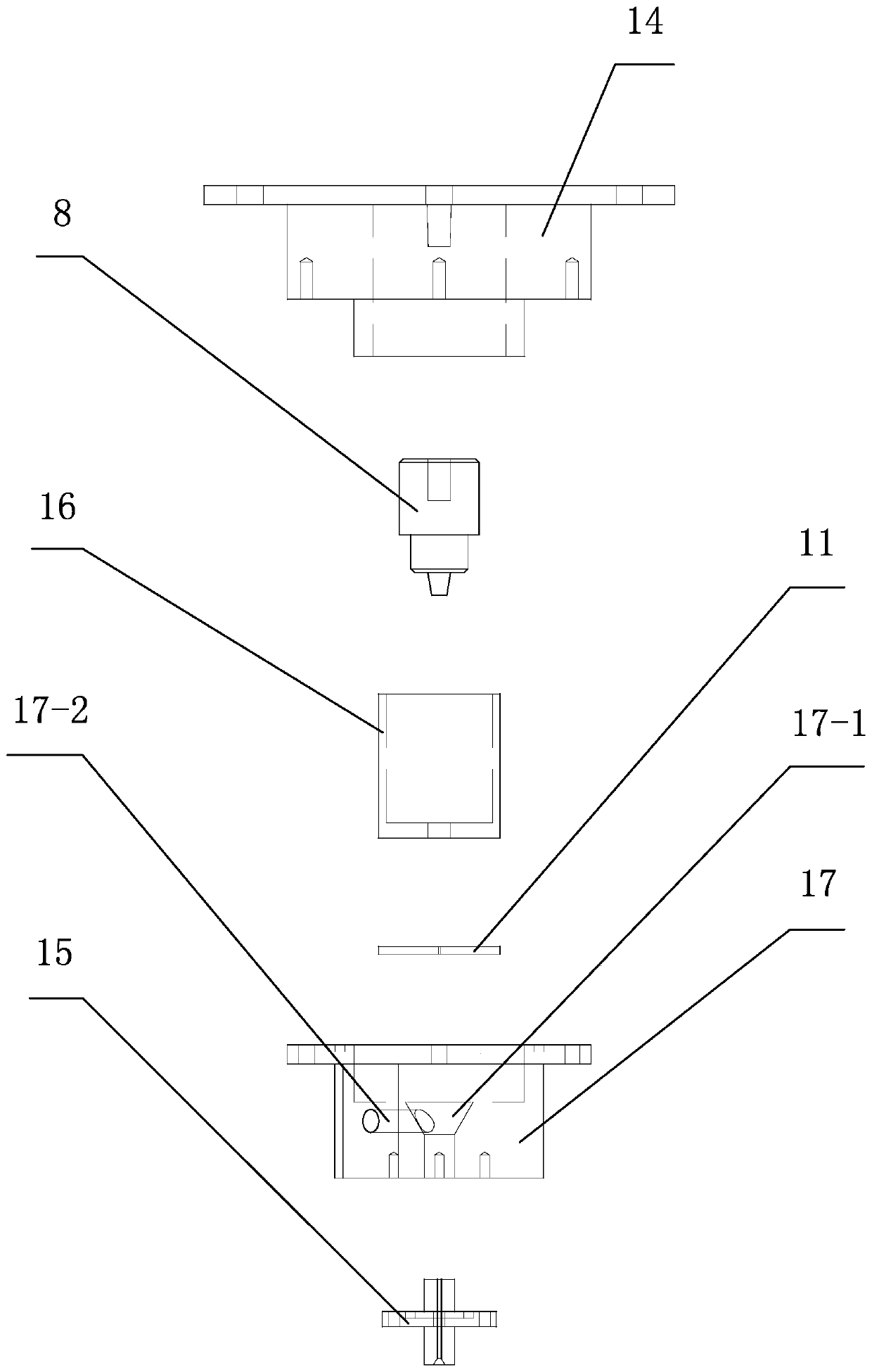

[0029] The fluid flow control device includes a flow diverter 2, and the flow diverter 2 includes a sandwich upper seat 14, an upper centering chuck 8, an isolation sleeve 16, a drainage lower seat 17 and a drainage head 15, and the sandwich upper seat 14 is installed on the At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com