Large-aperture schlieren system suitable for test section of wind tunnel

A wind tunnel test, large-caliber technology, applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve the problems of schlieren system sensitivity and background illumination uniformity decrease, high cost, etc. Decreased background illumination uniformity, addressing security risks, addressing costly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

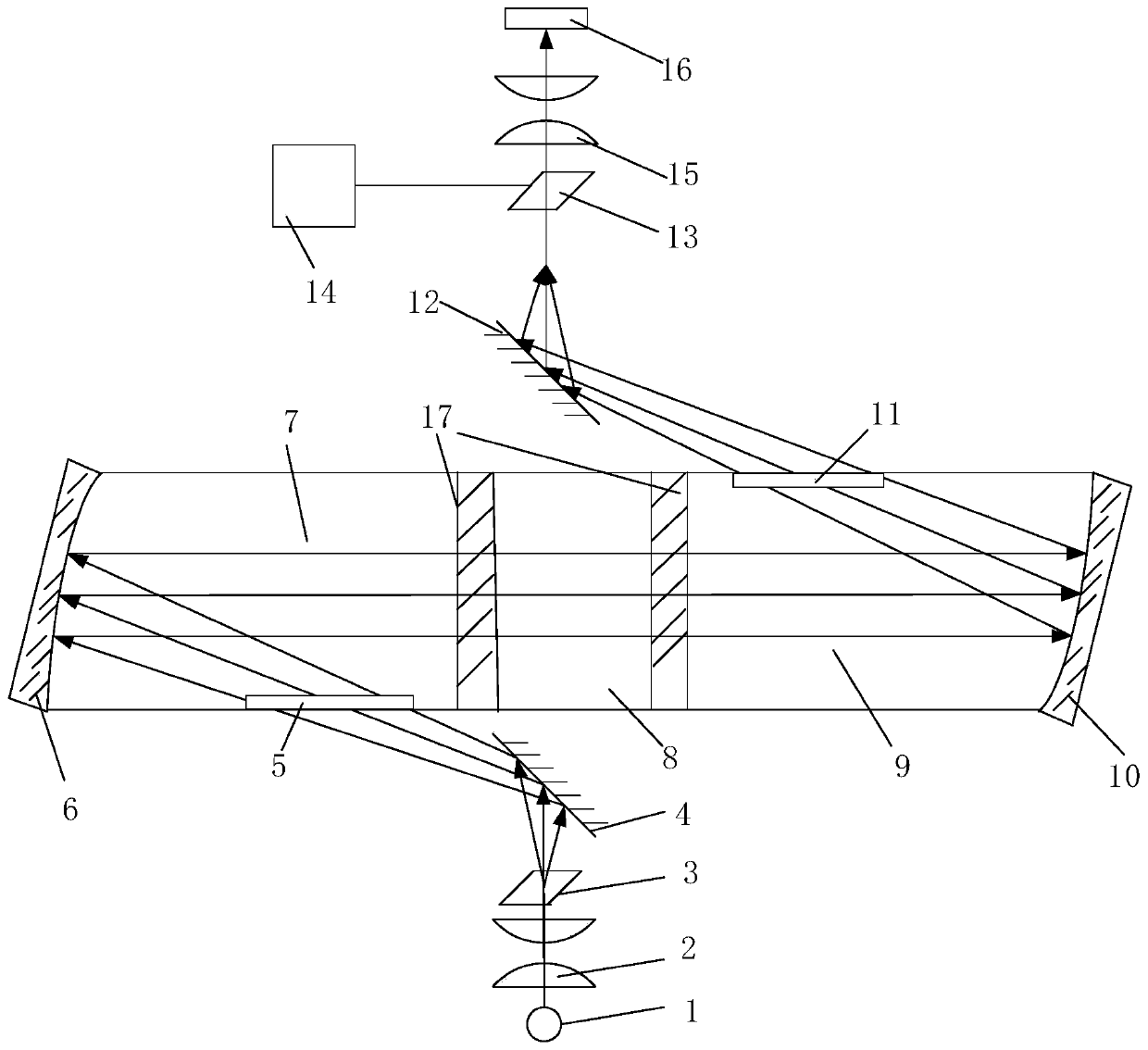

[0022] Such as figure 1 As shown, the present invention provides a large-diameter schlieren system suitable for the wind tunnel test section, including a light source system, a sealed front observation window 5, a collimating main reflector 6, a sealed front schlieren lens barrel 7, a test cabin 8, After sealing the schlieren lens barrel 9, the schlieren main reflector 10, the sealing rear observation window 11 and the imaging system. The sealed front observation window 5, the collimating main reflector 6, and the sealed front schlieren lens barrel 7 constitute a schlieren system.

[0023] The light source system includes an ultra-high-brightness LED lamp 1, a condenser lens group 2, a slit 3, and a first plane reflector 4, and the slit is a "mouth"-shaped slit. The ultra-high brightness LED lamp 1 should have a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com