Heat flux sensor and preparation method thereof

A technology of heat flow sensor and thermal resistance layer, which is applied in the field of heat flow sensor and its preparation, can solve the problems of difficult design of thin-film thermocouples, easy introduction of errors, complicated process, etc., and achieve the effects of facilitating measurement, reducing interference, and reducing overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

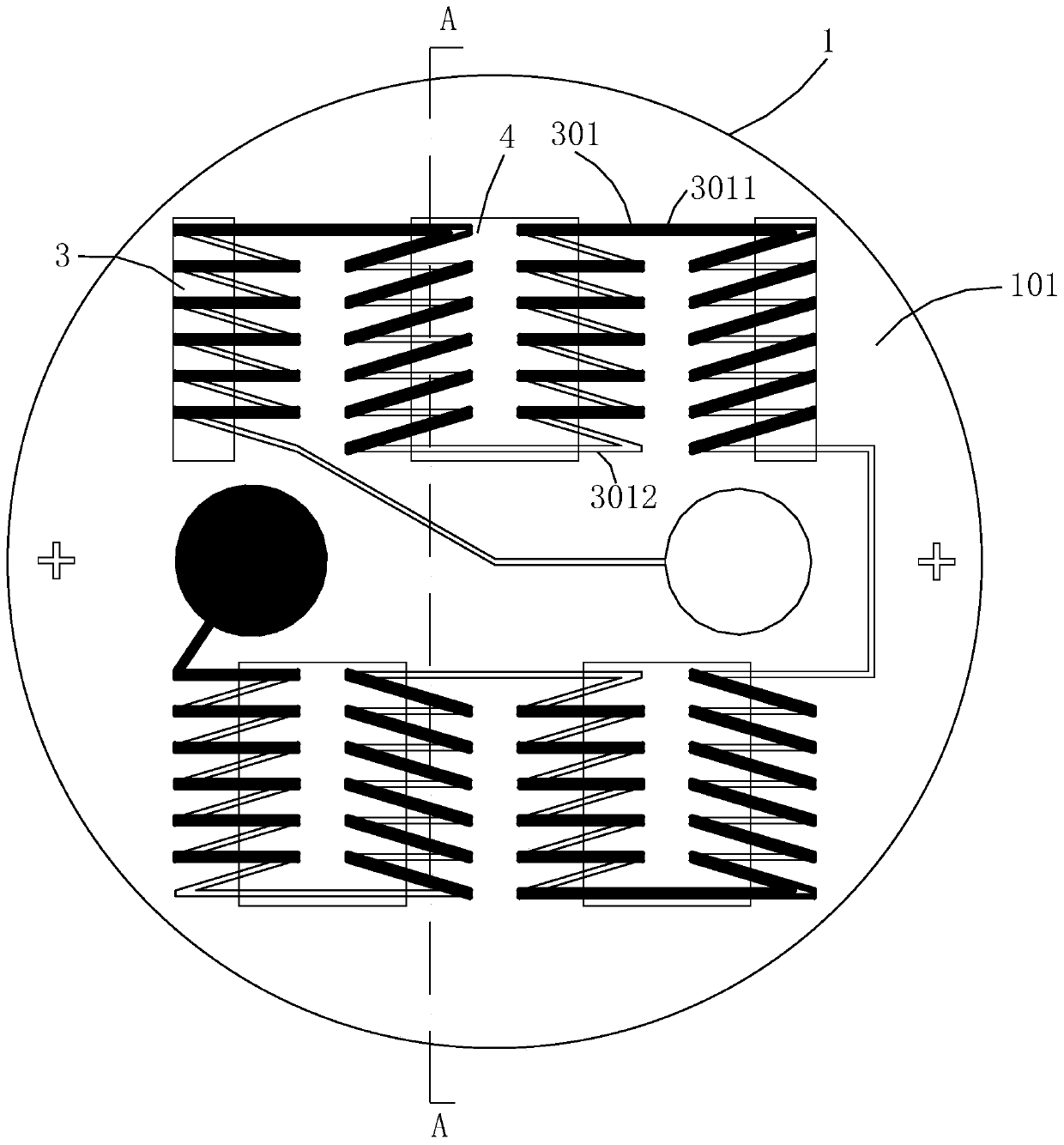

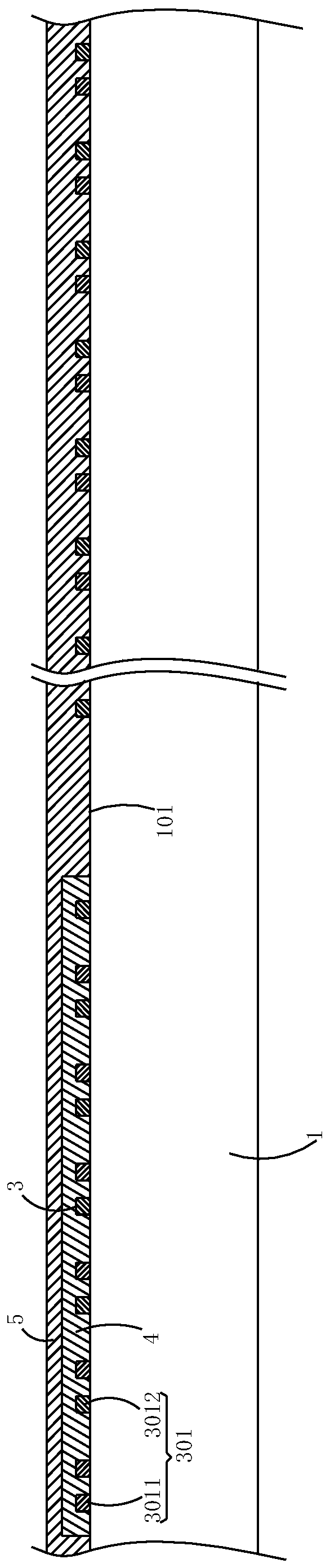

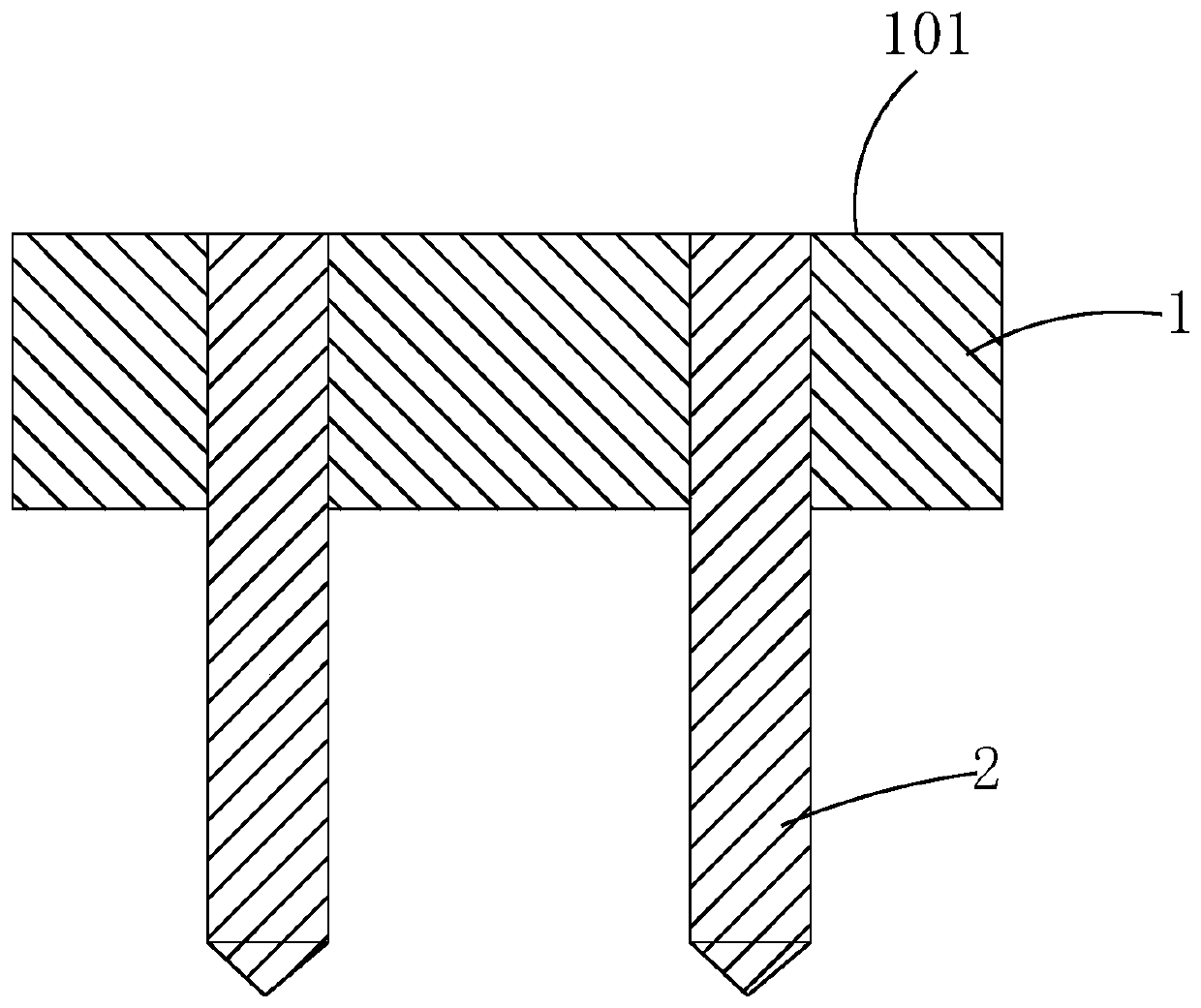

[0030] Such as figure 1 As shown, the heat flow sensor of this embodiment is suitable for the test environment of a pulsed hypersonic wind tunnel, and includes an electrode 2 and a probe 1 with electrical insulation properties. The probe 1 and the electrode 2 are integrally sintered; the electrode 2 One end of the probe 1 is embedded into the probe 1 and one end is flush with the measuring surface 101 of the probe 1. The side of the probe 1 that is flush with the electrode 2 is the measuring surface 101; directly deposited on the measuring surface 101 of the probe 1 is Thermopile 3, the two ends of thermopile 3 (as figure 1 shown by the two circles in ) are respectively deposited on the end faces of the electrodes 2; the thermopile 3 includes a plurality of thermocouple units 301 connected in series in sequence, and the thermocouple units 301 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com