Axle gear box of material transport cart

A technology for axle gearboxes and transport vehicles, which is applied to gear transmissions, gear lubrication/cooling, belts/chains/gears, etc. It can solve the problems of technology being restricted by people and high cost, and achieve compact space structure, light weight, and low manufacturing cost. The effect of cycle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

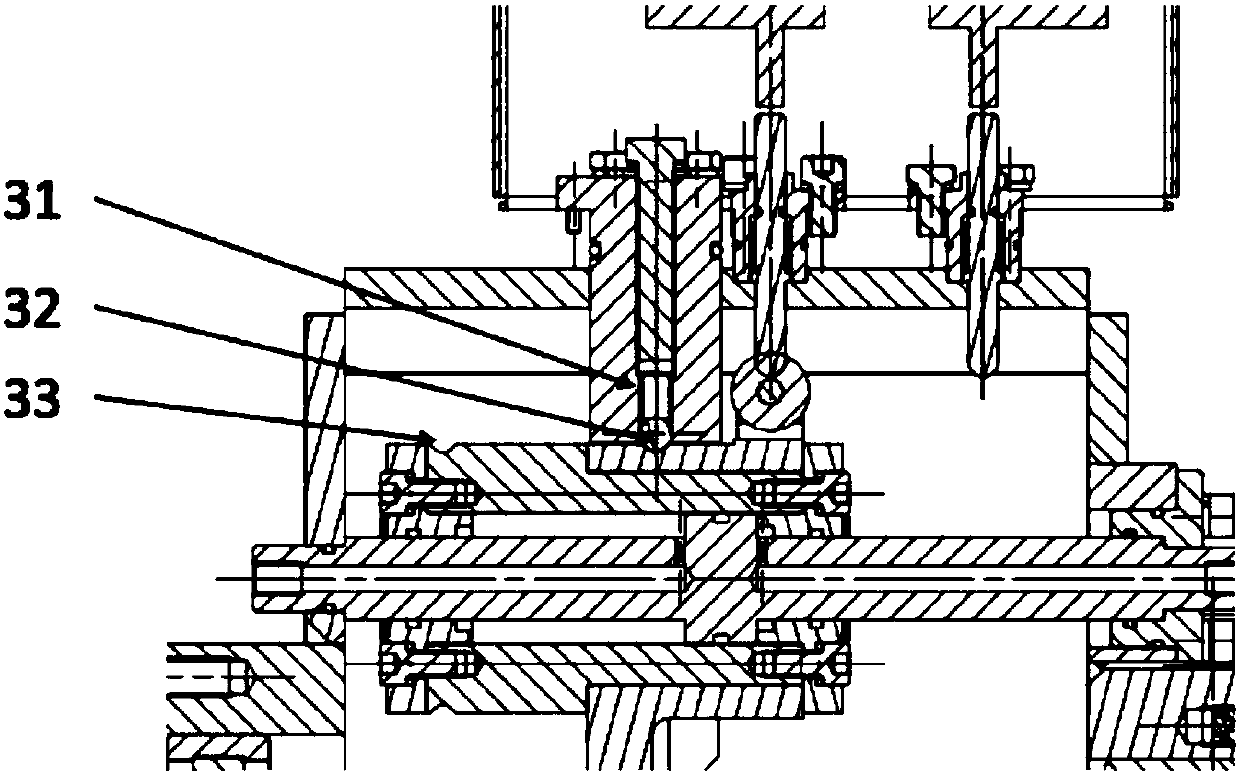

[0029] Embodiment 1.1: a kind of material transport vehicle axle gear box, as figure 1 and Figure 6 As shown, it includes a welding box 2, and a first-stage reduction mechanism 1 is arranged in the welding box 2. The first-stage reduction mechanism 1 includes two gears I and II that mesh with each other, and the gear I is set on the material transport vehicle. On the axle of the wheel, the gear II is installed on the intermediate shaft, and the gear III7 is also set on the intermediate shaft. The gear III7 meshes with the gear IV54, and the gear IV54 is set on the input shaft 6. The gear III and the gear IV form two Stage reduction mechanism, the space between gear IV54 and gear III top is provided with shifting mechanism 3.

[0030] Described gear I, gear II, gear III and gear IV54 are spur gears.

[0031] The shifting mechanism 3 of the axle gear box of the material transport vehicle adopts a built-in oil cylinder to drive a sliding gear shifting mode. The gear IV54 is po...

Embodiment 21

[0044] Embodiment 2.1: A gear-on and off-gear method for the axle gearbox of a material transport vehicle, which includes:

[0045] a. When the control system initiates the shifting action, the left chamber of the shift oil cylinder 52 enters the oil, pushing the oil cylinder body to move to the left, driving the shifting gear on the fork (that is, gear IV) to mesh with the gear III on the intermediate shaft, and the shifting is performed ;

[0046] b. After the shifting is completed, the left chamber of the shifting oil cylinder maintains pressure to maintain the shifting state;

[0047] c. When the control system initiates a disengagement action, oil enters the right chamber of the shift oil cylinder, pushing the oil cylinder body to move to the right, and drives the shifting gear on the fork (that is, gear IV) to disengage from the gear III on the intermediate shaft to perform disengagement ;

[0048] d. After the disengagement is completed, the disengagement state is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com