Interlayer formwork for aseismatic joint construction, and mounting method of interlayer formwork

A technology of anti-seismic joints and templates, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and preparation of building components on site, which can solve problems such as building damage and reduce construction costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

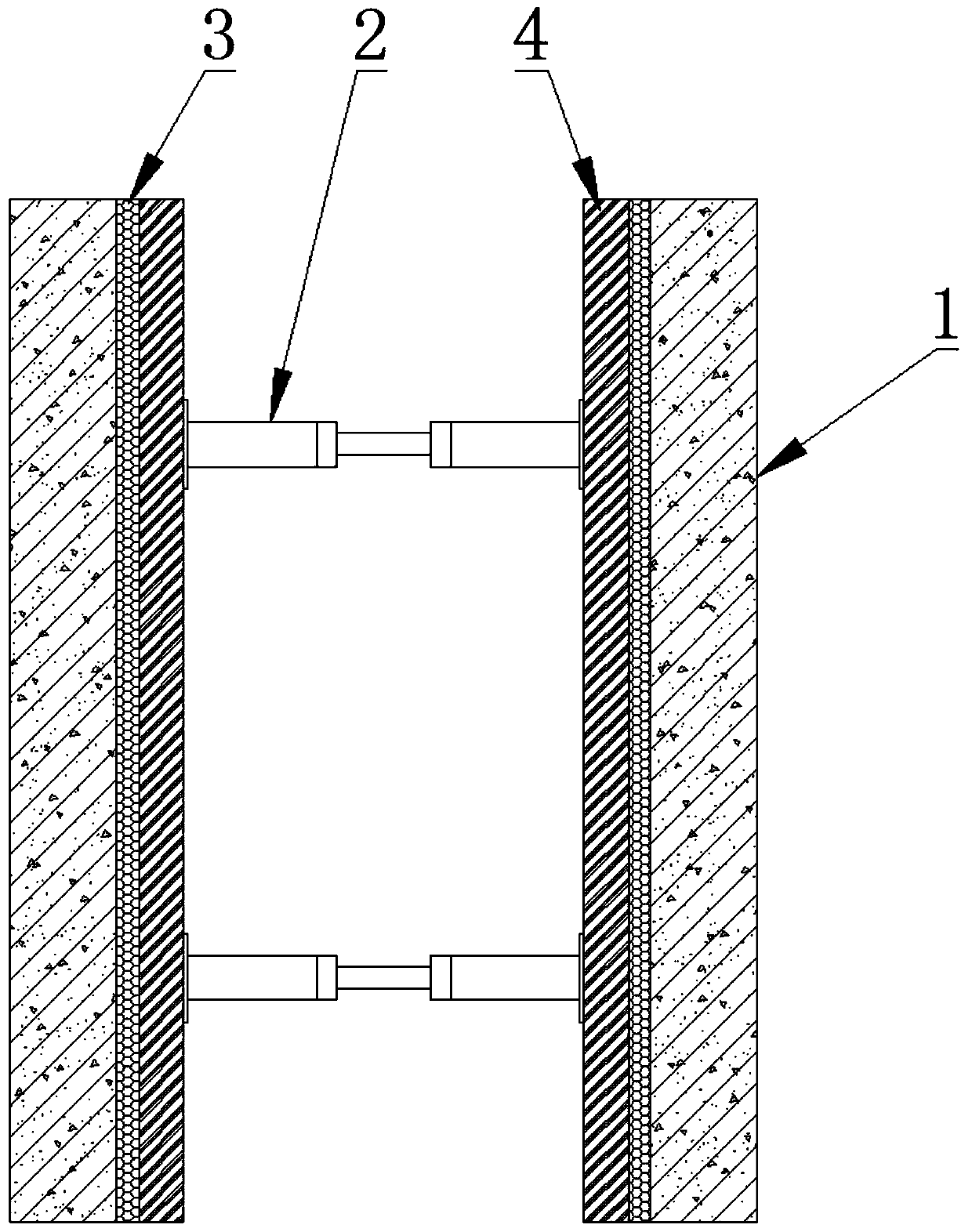

[0033] A sandwich formwork for seismic joint construction, comprising a formwork 4 for supporting the formwork and a support device 2 connected to one side of the formwork 4 and used to support the formwork 4, on the other side of the formwork 4 A non-stick board 3 connected with the body of wall 1 is connected.

[0034] Further, the supporting device 2 includes a screw, an intermediate tube sleeved on the screw, and two telescopic tubes connected to both ends of the intermediate tube.

[0035] Further, the support device 2 also includes a level nested on the middle pipe.

[0036] Further, there is a hexagonal structure on the outside of the telescopic tube on the support device 2 .

[0037] Further, the non-stick board 3 is a perlite board with a thickness of 5-8 mm.

[0038] Further, the template 4 is an aluminum template with a thickness of 10-15mm.

[0039] Further, the template 4 is provided with a fixing seat fixedly connected with the supporting device 2 .

[0040] ...

Embodiment 2

[0051] A sandwich formwork for seismic joint construction, comprising a formwork 4 for supporting the formwork and a supporting device 2 connected to one side of the formwork 4 and used to support the formwork 4, on the other side of the formwork 4 A non-stick board 3 connected with the body of wall 1 is connected. The supporting device 2 and the non-stick board 3 are located on both sides of the same axis of the template 4 .

[0052]Further, the supporting device 2 includes a screw, an intermediate tube sleeved on the screw, and two telescopic tubes connected to both ends of the intermediate tube. Two mutually symmetrical and coaxial anti-rotation screws are screwed on the side walls of both ends of the intermediate pipe; both ends of the screw rod have external threads. The inner ends of the two telescopic tubes are provided with screw holes matched with the screw rods; and the anti-rotation screws match the outer surfaces of the inner ends of the two telescopic tubes. The...

Embodiment 3

[0069] A sandwich formwork for seismic joint construction, comprising a formwork 4 for supporting the formwork and a support device 2 connected to one side of the formwork 4 and used to support the formwork 4, on the other side of the formwork 4 A non-stick board 3 connected with the body of wall 1 is connected. The support device 2 and the non-stick board 3 are located on both sides of the same axis of the template 4 .

[0070] Further, the supporting device 2 includes a screw, an intermediate tube sleeved on the screw, and two telescopic tubes connected to both ends of the intermediate tube. Two mutually symmetrical and coaxial anti-rotation screws are screwed on the side walls of both ends of the intermediate pipe; both ends of the screw rod have external threads. The inner ends of the two telescopic tubes are provided with screw holes matched with the screw rods; and the anti-rotation screws match the outer surfaces of the inner ends of the two telescopic tubes. The midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com