Label production line and technology for producing label

A production line and label technology, applied in the post-processing of printing, general parts of printing machinery, printing, etc., can solve the problem of inability to complete the processing of multi-layer film labels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

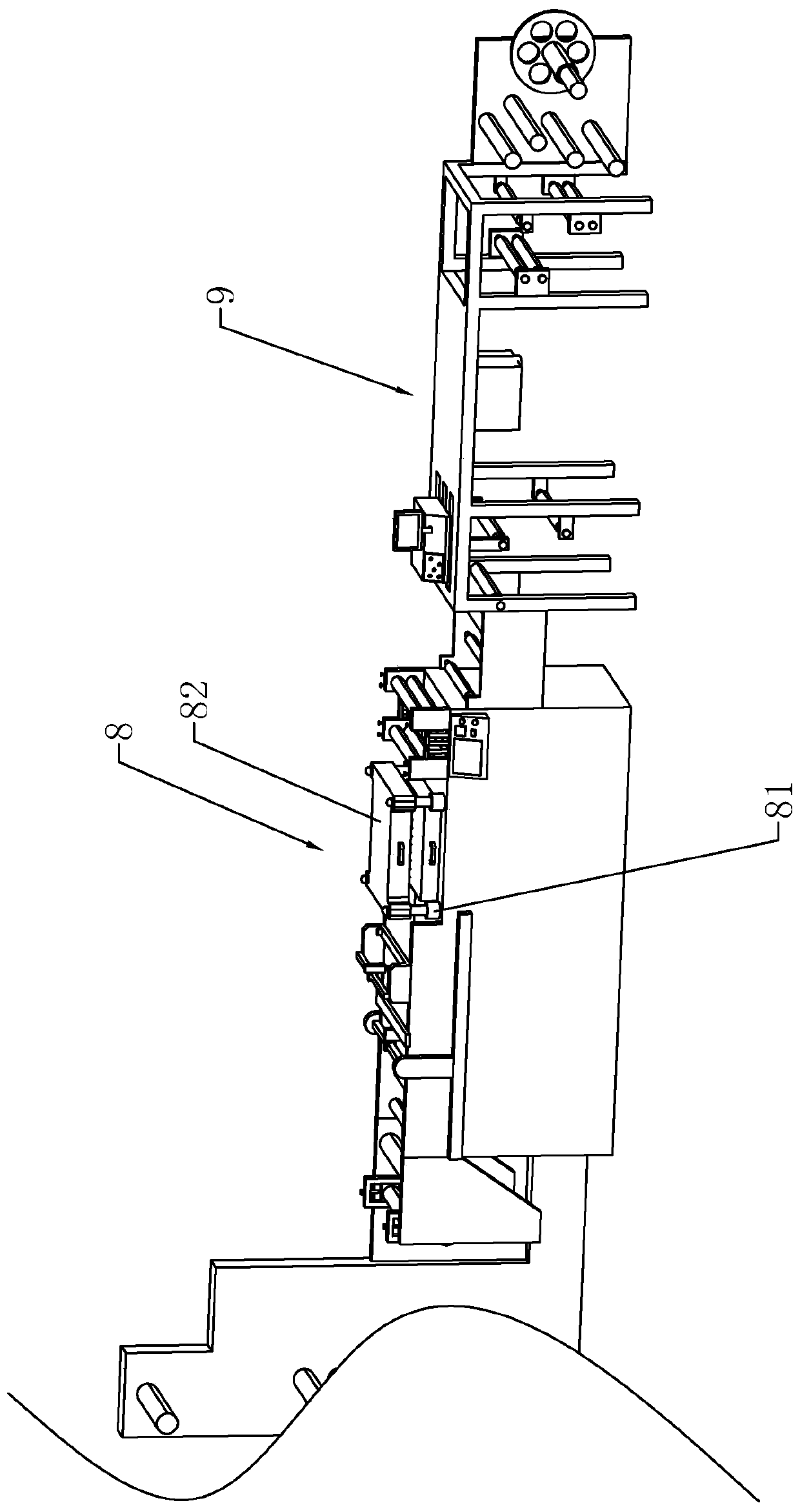

[0042] Embodiment 1: a kind of label production line, such as figure 1 As shown, it includes a satellite type rotary machine 1, and the satellite type rotary machine 1 is rotatably connected with a feed wheel 11 powered by a motor. The rotation completes the work of transporting the backing paper.

[0043] combine figure 1 with figure 2 As shown, a feeding roller group 12 is installed next to the feeding wheel 11, and the feeding roller group 12 includes a plurality of rollers that can rotate freely. Roller, the bottom paper passes through a plurality of rollers to make the bottom paper tight, and then enters on the feeding wheel 11.

[0044] combine figure 1 with figure 2 As shown, the feeding wheel 11 is rotatably connected with several composite rollers 13, the radius of the composite rollers 13 is much smaller than the radius of the feeding wheel 11, and the composite rollers are evenly arranged along the circumferential direction of the feeding wheel 11. In the pr...

Embodiment 2

[0062] Embodiment 2: a kind of technique of label production, such as Figure 9 shown, including:

[0063] S1: Production preparation, prepare the corresponding ink and materials according to the production requirements, formulate the production plan, determine whether to choose ink printing or rubber surface printing or glazing film compounding, and then the staff chooses to open the corresponding printing equipment and adjust the corresponding feeding Rotating speed of wheel 11, such as the corresponding parameters such as the rotating speed of roller and feeding wheel 11, the liquid output volume of ink tank 24, the operating voltage of electric spark and the rotating speed of roller.

[0064] S2, trial printing, first adjust the position of the rollers in the feeding roller group 12, then install the backing paper on the feeding roller group 12, the backing paper passes through the corresponding printing equipment, and then observe the printing situation, the main observat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com