Sticky label paper processing technology

A technology of processing technology and label paper, which is applied in metal processing, printing technology, cardboard items, etc., can solve the problems such as the inability to adjust the punching device, the inability to adapt to the label, and troublesome cleaning, so as to improve the punching efficiency, increase the scope of application, The effect of reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

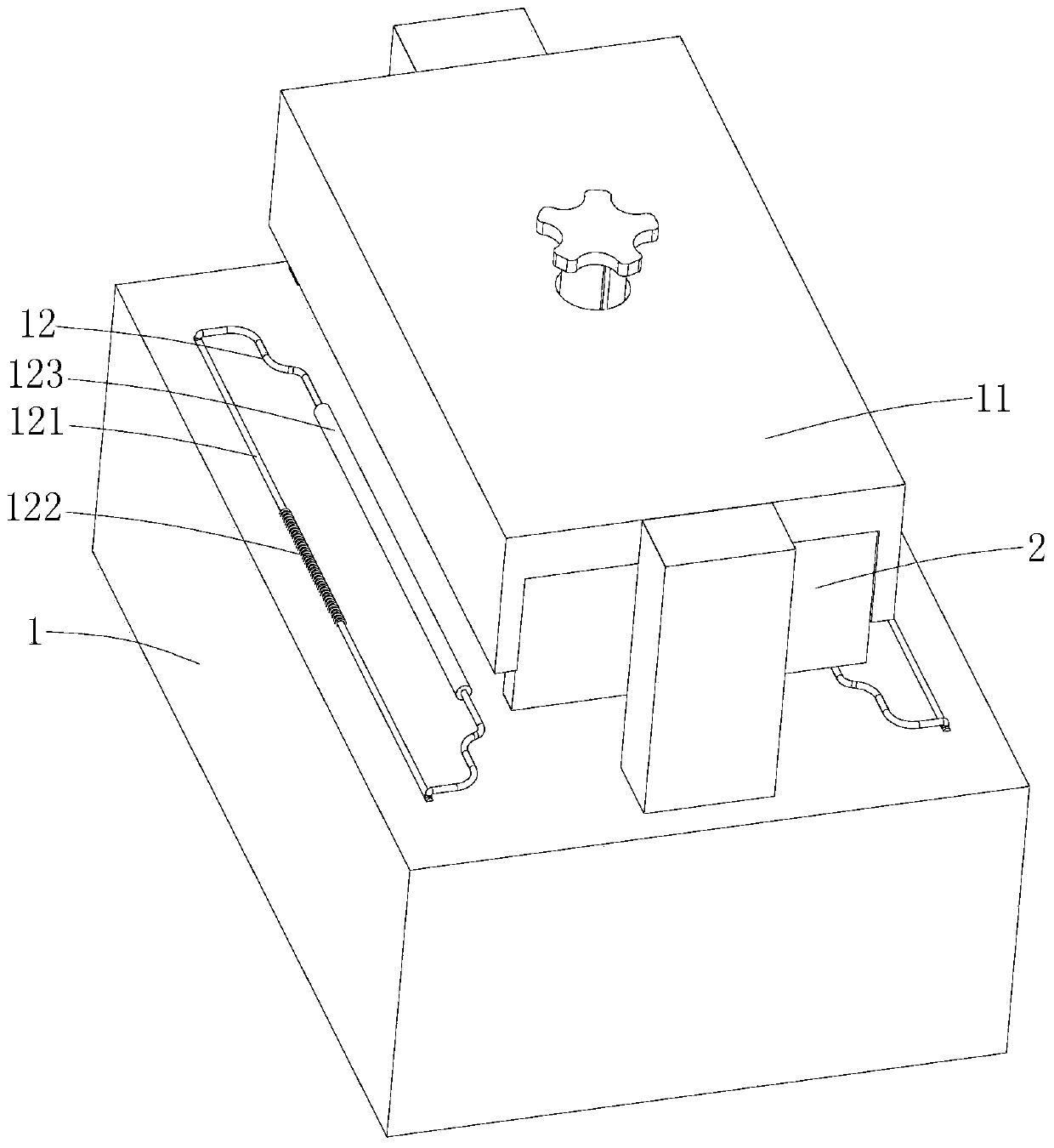

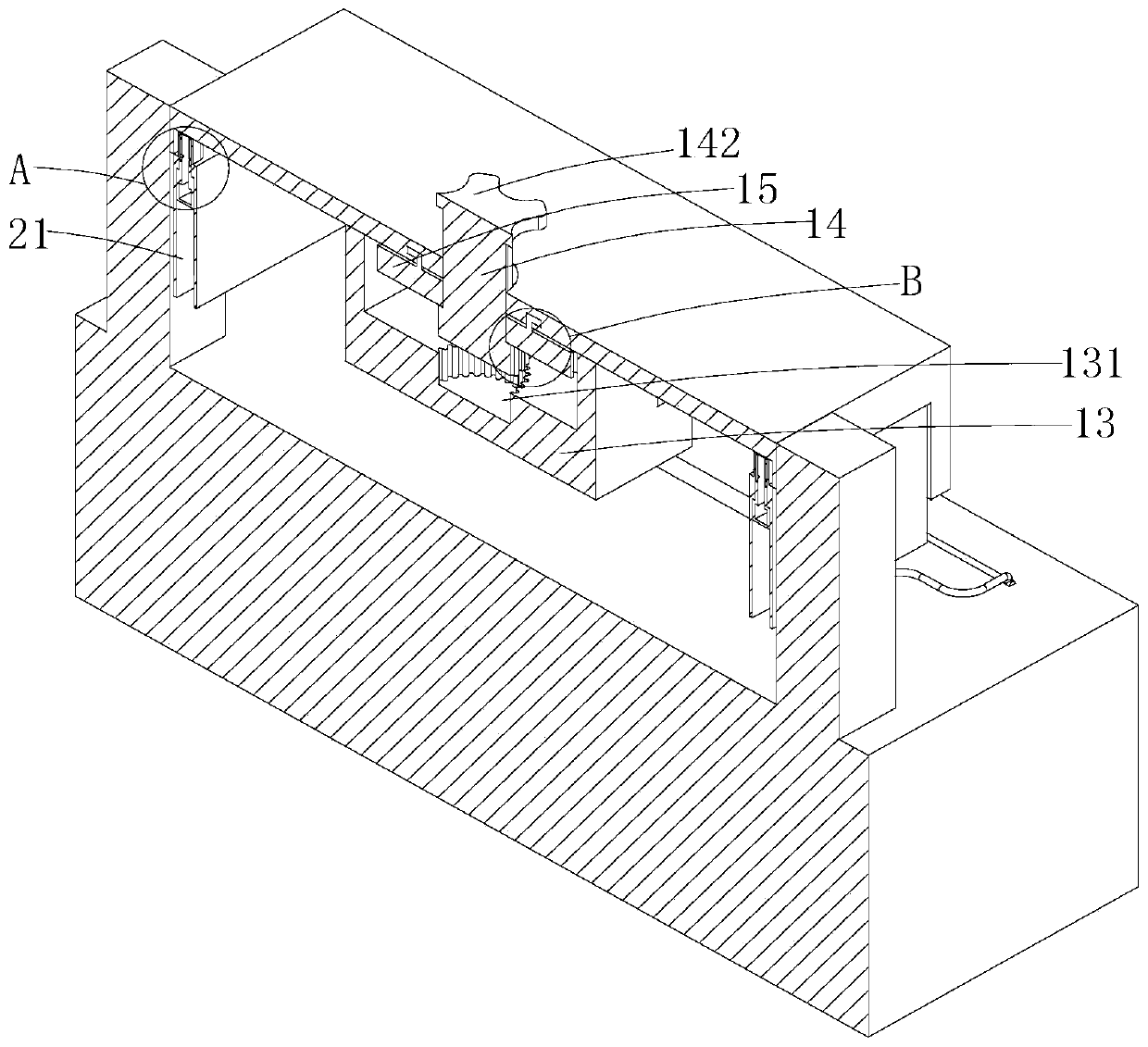

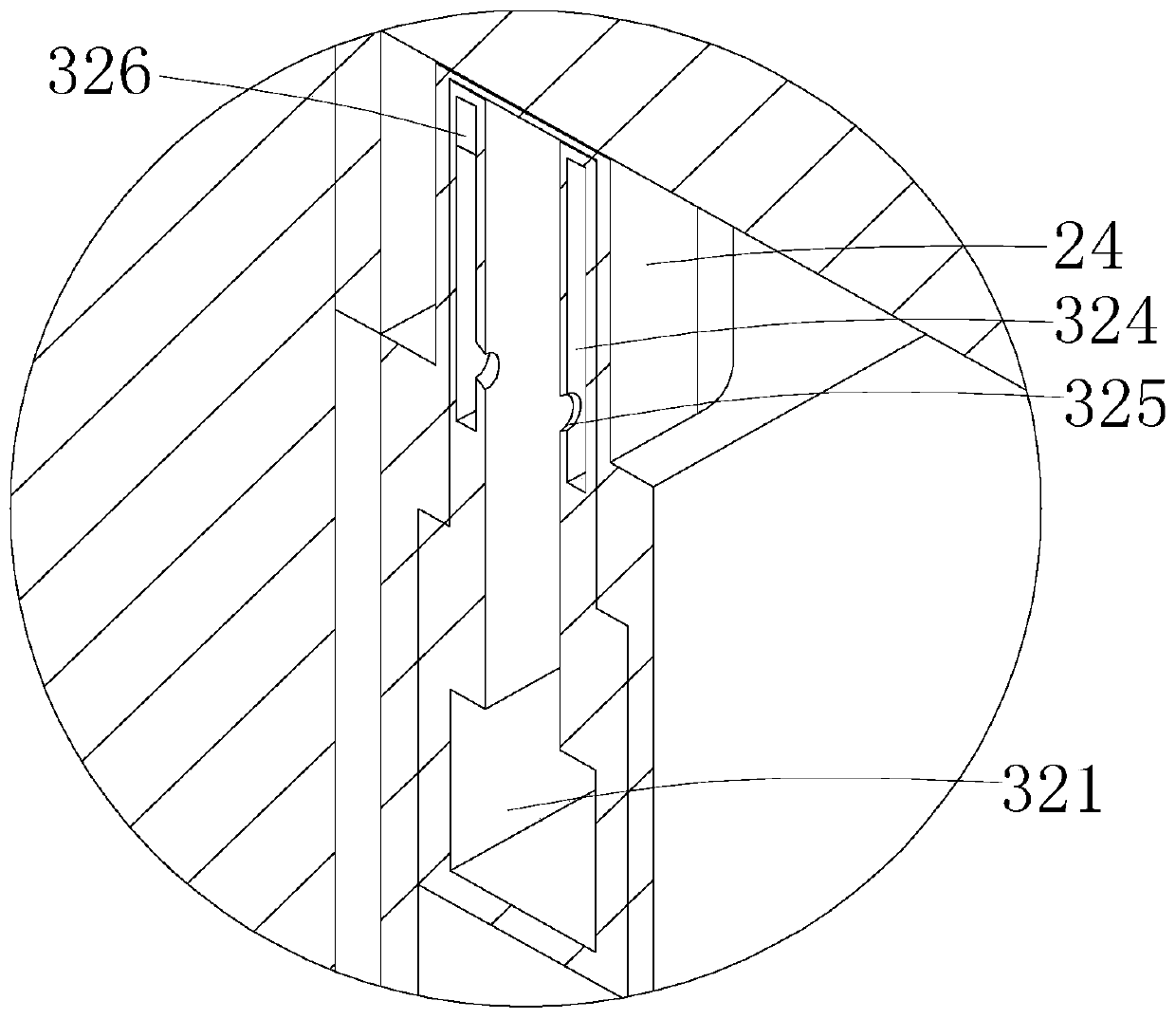

[0024] A self-adhesive label paper processing technology, a. unwinding: the self-adhesive label base paper rolled into a roll is unfolded and transported to the next process smoothly by unwinding equipment; b. printing: the pattern or text is printed on the paper by printing machinery On the self-adhesive label base paper; c. Glazing: apply a layer of varnish on the self-adhesive label base paper; d. Hot stamping: make the pattern or text clear and beautiful, the color is bright and eye-catching, wear-resistant and weather-resistant; e. Punching: Punch out the required holes on the self-adhesive label base paper through the punching equipment; f. Die-cutting: Cut the continuous self-adhesive label base paper into semi-finished products of predetermined length through a cutting machine; g. Unqualified semi-finished products are rejected; h. Cut sheet: the label will be cut into a predetermined size label by a sheet cutter; the printing ink uses UV label printing ink; the use of ...

Embodiment 2

[0032] A self-adhesive label paper processing technology, a. unwinding: the self-adhesive label base paper rolled into a roll is unfolded and transported to the next process smoothly by unwinding equipment; b. printing: the pattern or text is printed on the paper by printing machinery On the self-adhesive label base paper; c. Glazing: apply a layer of varnish on the self-adhesive label base paper; d. Hot stamping: make the pattern or text clear and beautiful, the color is bright and eye-catching, wear-resistant and weather-resistant; e. Punching: Punch out the required holes on the self-adhesive label base paper through the punching equipment; f. Die-cutting: Cut the continuous self-adhesive label base paper into semi-finished products of predetermined length through a cutting machine; g. Unqualified semi-finished products are rejected; h. Cut sheet: the label will be cut into a predetermined size label by a sheet cutter; the printing ink uses UV label printing ink; the use of ...

Embodiment 3

[0035] A self-adhesive label paper processing technology, a. unwinding: the self-adhesive label base paper rolled into a roll is unfolded and transported to the next process smoothly by unwinding equipment; b. printing: the pattern or text is printed on the paper by printing machinery On the self-adhesive label base paper; c. Glazing: apply a layer of varnish on the self-adhesive label base paper; d. Hot stamping: make the pattern or text clear and beautiful, the color is bright and eye-catching, wear-resistant and weather-resistant; e. Punching: Punch out the required holes on the self-adhesive label base paper through the punching equipment; f. Die-cutting: Cut the continuous self-adhesive label base paper into semi-finished products of predetermined length through a cutting machine; g. Unqualified semi-finished products are rejected; h. Cut sheet: the label will be cut into a predetermined size label by a sheet cutter; the printing ink uses UV label printing ink; the use of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com