Non-ferrous metal rod variable-frequency induction gradient heating device and heating method

A gradient heating and metal rod technology, applied in the field of metal processing, can solve the problems of changes in mechanical properties and dimensions, lower yields, high energy consumption, etc., and achieve the effects of consistent dimensions, stable mechanical properties, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Embodiment, the heating of copper, gold and silver rods adopts the method ② of step 3) to realize, and the method ① of step 3) is adopted for aluminum and magnesium rods.

[0040] Induction heating by alternating electromagnetic field;

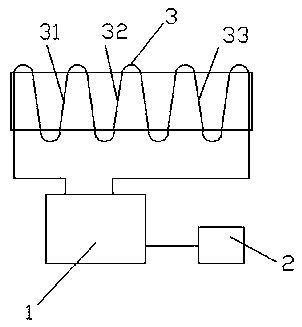

[0041] The alternating current generated by the variable frequency power supply is input into the induction coil of the variable frequency induction gradient heating furnace, and an alternating magnetic field is generated in the induction coil. The heated metal rod is located in the alternating magnetic field, and the electrons in the metal rod move directionally under the action of the alternating magnetic field. An induced current is generated, which heats the aluminum rod.

[0042] Principle of energy conservation:

[0043] The temperature rise of a heated object is proportional to the energy absorbed. The energy of induction heating relies on the induction coil to generate an alternating magnetic field, so the coil density per uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com