An umbrella-shaped antenna deployment mechanism combined with a fixed-axis gear train and a lead screw

A technology of fixed-axis gear train and umbrella antenna, which is applied to folding antennas, mechanical equipment, belts/chains/gears, etc., can solve the problems of large impact of umbrella antenna deployment, large antenna storage volume, and inability to automatically fold, etc. Reliable shape, stable unfolding process, and the effect of avoiding gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

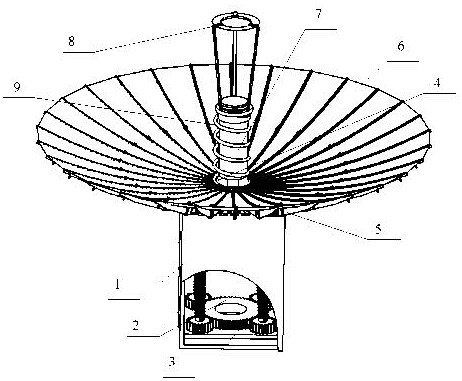

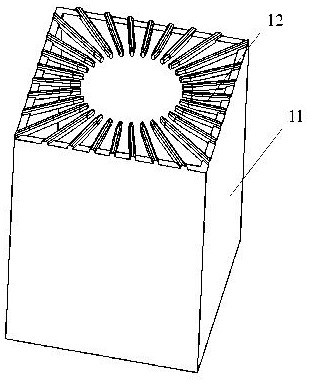

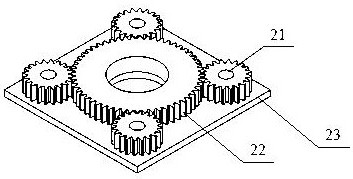

[0037] refer to figure 1, the present invention includes an antenna storage tube 1, a fixed-axis gear train 2, a screw 3, a central hub 4, an antenna rib 5, a screen reflective surface 6, a feed horn 7, a secondary reflective surface 8, and a spring 9. The antenna The storage tube 1 is a fixed component, which is used to envelop the folded state of the entire umbrella antenna; the fixed-axis gear train 2 is installed at the bottom of the storage tube 1, and each gear can rotate around its own axis; the lead screw 3. The lower end is fixedly connected with the gear corresponding to the fixed shaft gear train 2 with the coaxial center, that is, it is integrated with the gear; the central hub 4 is connected with the lead screw 3 through a transmission thread, so that the rotation of the lead screw 3 drives the center hub 4; the antenna rib 5 is connected to the central hub 4 by a hinge, so that its root can rotate around the hinge; the silk screen reflection surface 6 is laid on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com