Graphene modified heterogeneous composite material and preparation method and application thereof

A graphene modification, composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of MoO2 volume change, capacity drop, etc., achieve good charge-discharge cycle performance, limit loss, synthesis method Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

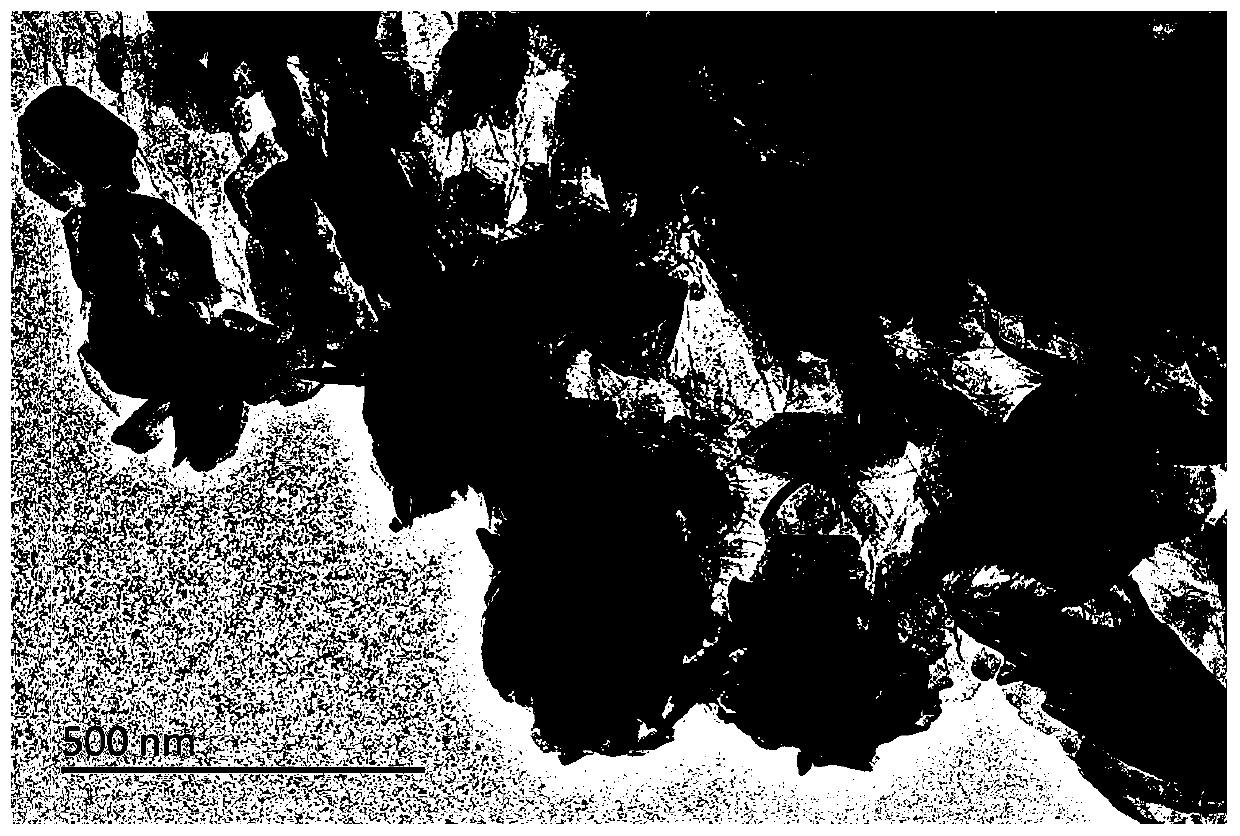

[0029] Example 1 Preparation of MoS 2 / MoO 2 / graphene composites

[0030] Take 100mL of sodium molybdate dihydrate solution (concentration of 0.2mol / L) and 100mL of thiourea solution (concentration of 1.5mol / L), mix and fully stir, and let stand for 6h. Add graphene aqueous dispersion (solid content 15%), mix and stir (stirring rate 200rpm), process 30min at ultrasonic power 500W. The mixed solution was subjected to hydrothermal reaction at 180°C for 3 hours. After the hydrothermal reaction, the precipitate was separated and washed with water to completely remove sodium ions. The dried precipitate was treated at a high temperature of 600° C. for 3 hours under a nitrogen atmosphere, and cooled in a furnace after the reaction to obtain the target product. Elemental analysis tests show that MoS in the final product 2 Accounting for 69.5% of the total mass ratio of the composite, MoO 2 It accounts for 25.3% of the total mass ratio of the composite material, and the rest is ...

Embodiment 2

[0032] Example 2 Preparation of MoS 2 / MoO 2 / graphene composites

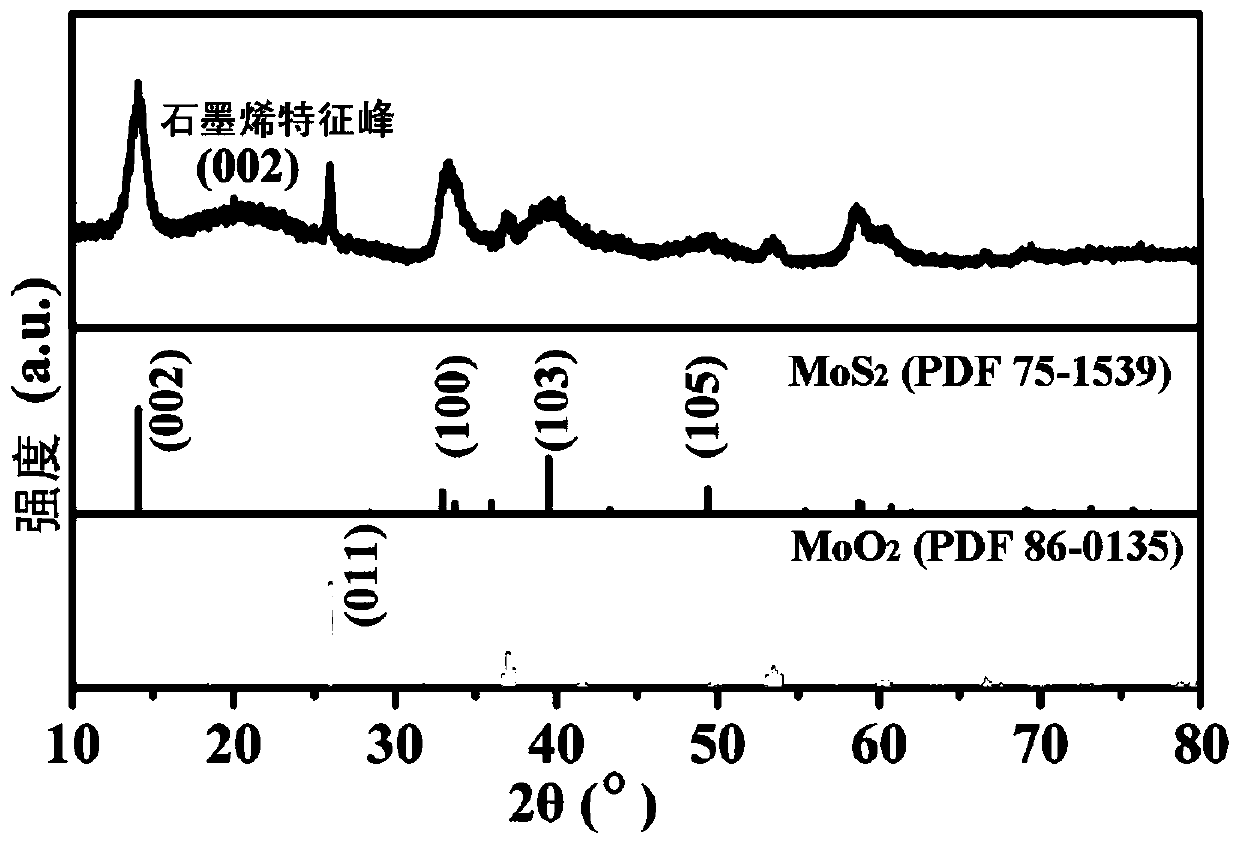

[0033] Take 100mL of sodium molybdate dihydrate solution (concentration of 0.5mol / L), 100mL of thiourea solution (concentration of 1.0mol / L), mix and fully stir, and let stand for 6h. Add graphene aqueous dispersion (solid content 20%), mix and stir (stirring rate 400rpm), process 1h at ultrasonic power 700W. The mixed solution was subjected to hydrothermal reaction at 200°C for 6 hours. After the hydrothermal reaction, the precipitate was separated and washed with water to completely remove sodium ions. The dried precipitate was treated at a high temperature of 800° C. for 3 hours under a nitrogen atmosphere, and cooled in a furnace after the reaction to obtain the target product. The spectrum peaks of the obtained product X-ray diffraction pattern and the MoS 2 、MoO 2 The standard peaks are exactly the same, and the half-width of the peaks is larger, indicating that the MoS in the sample 2 and MoO 2 ...

Embodiment 3

[0034] Example 3 Preparation of MoS 2 / MoO 2 / graphene composites

[0035] Take 100mL of sodium molybdate dihydrate solution (solution concentration is 1.0mol / L), 100mL of thiourea solution (concentration is 0.5mol / L), mix and fully stir, let stand for 6h. Add graphene aqueous dispersion (solid content 20%), mix and stir (stirring rate 600rpm), ultrasonic power 800W for 2h. The mixed solution was treated with hydrothermal reaction at 220°C for 6 hours. After the hydrothermal reaction is completed, the precipitate is separated and washed with water to completely remove sodium ions. The dried precipitate was treated at a high temperature of 850° C. for 3 hours under a nitrogen atmosphere, and cooled in a furnace after the reaction to obtain the target product. Elemental analysis tests show that MoS in the final product 2 Accounting for 40.2% of the total mass ratio of the composite material, MoO 2 It accounts for 55.1% of the total mass ratio of the composite material, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com