Electrical circuit current detection method based on magnetometer sensor

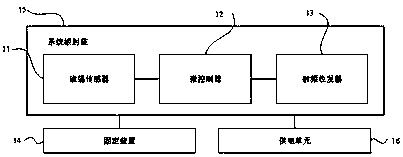

A magnetic sensor and line current technology, applied in the direction of only measuring current, measuring current/voltage, instruments, etc., can solve problems such as circuit damage, difficulty in detecting the magnitude of the electric current, and difficulty in overall shielding, so as to ensure measurement accuracy , Conducive to mass production, save the effect of installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

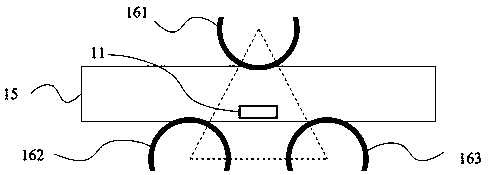

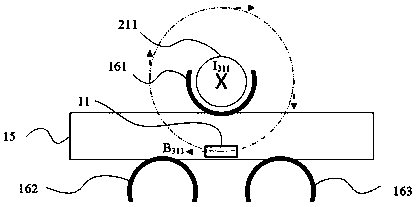

[0027] An example of current detection of a single cable circuit using the method described in this patent is image 3 shown. Method The device is attached to the cable under test 211 through the upper fixing device 161 without disconnecting the cable under test 211 . The lower left fixing device 162 and the lower right fixing device 163 do not need to be connected and can be left empty. Current I in the tested cable 211 311 The direction flows into the paper, according to Ampere's law, the current I 311 A circumferentially distributed induced magnetic field will be formed around the cable 211, including the magnetic field B falling on the magnetic sensor 11 311 strength. The magnetic sensor should have at least one sensitive axis, and there should be one sensitive axis and magnetic field B 311 The magnetic induction is parallel. Thus, the magnetic field B 311 Can be measured by the magnetic sensor 11, forming a magnetic field B 311 The magnetic induction intensity is ...

Embodiment 2

[0029] The implementation example of using the method described in this patent to monitor the current of the live line and neutral line cable of single-phase AC mains power Figure 4 shown. Method The device is attached to a pair of tested live wire 222 and neutral wire 223 cables through the left lower fixing device 162 and the right lower fixing device 163. Typically, the left lower fixing device 162 is attached to the live wire 222 cable, and the right The lower fixing device 163 is attached to the neutral line 223 cable, and the upper fixing device 161 does not need to be installed and can be left empty. Current in live wire 222 cable and neutral current in 223 cable The directions flow into and out of the paper respectively, they are alternating currents with the same frequency and phase, and the amplitude can be expressed as:

[0030]

[0031]

[0032] where w is the frequency of the alternating current and t is the time.

[0033] According to Ampere's law, t...

Embodiment 3

[0055] Examples of using the method described in this patent to detect the current of a three-phase AC line are Image 6 shown. The intelligent microsystem is attached to the three phase lines of a group of three-phase lines through the upper fixing device 161 , the lower left fixing device 162 and the lower right fixing device 163 . According to the solution of this patent, the centers of the upper fixing device 161, the lower left fixing device 162, and the lower right fixing device 163 in the vertical section are equilateral triangles, and the geometric center is located at the center of the magnetic sensor 11. There are two sensitive axes, and there is no restriction on the direction of the axes. Typically, the upper fixing device is attached to the phase A cable 231 , the fixing device 162 is attached to the phase B cable 232 , and the fixing device 163 is attached to the phase C cable 233 . Current in A-phase cable 231 , B-phase cable 232 and C-phase cable 233 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com