Shatterproof ceramic product and preparation method thereof

A technology of ceramic products and ceramic blanks, which is applied in the field of anti-fall ceramic products and its production, which can solve the problems of easy breakage, poor mechanical properties, non-shock and drop resistance, etc., and achieve increased strength, good cohesiveness, and total reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

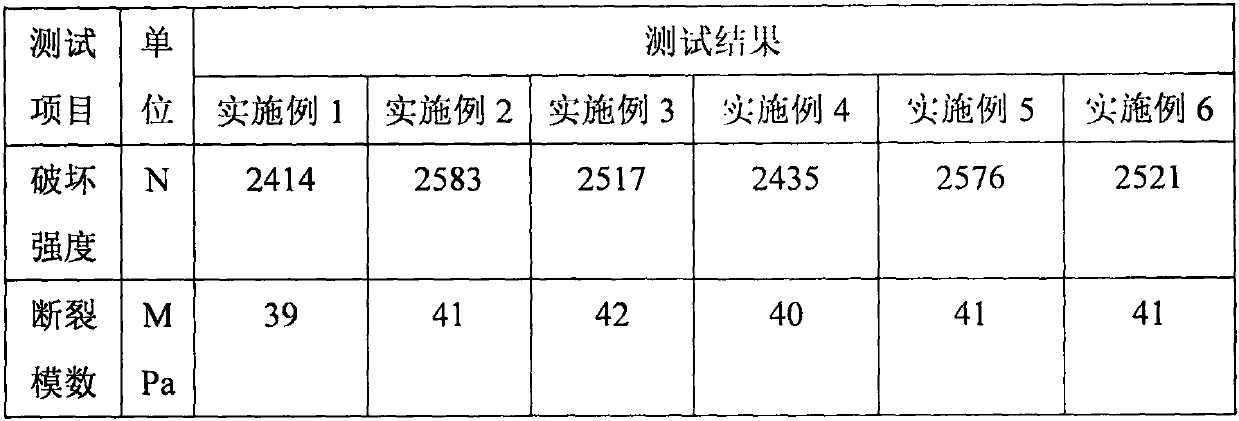

Examples

Embodiment 1

[0037] An anti-fall ceramic product. The ceramic blank is made of the following raw materials in parts by mass: 38 parts of kaolin, 32 parts of gneiss, 13 parts of rhodochrosite, 12 parts of orthoclase, 8 parts of nano zirconium disilicide, and 8 parts of red corundum 5 parts of magnesite, 9 parts of mullite whiskers, 5 parts of yttria stabilized zirconia, 7 parts of carbon fiber, 20 parts of wheat straw powder, 5 parts of sawdust, 5 parts of corn flour, and 6 parts of nano antibacterial powder.

[0038] The preparation method of this drop-resistant ceramic product comprises the following steps:

[0039] (1) Preparation of aggregate:

[0040] Take kaolin, gneiss, rhodochrosite, orthoclase, and magnesite, mix them evenly, crush them, pass through a 120-mesh sieve, add water to make a slurry with a mass concentration of 40%, and use wet ball milling with a ball milling speed of 800-1200r / min, ball mill 2;

[0041] Then use spray drying to remove water, calcined at 780°C for 4...

Embodiment 2

[0063] The basic process is the same as in Example 1, the difference is that the pottery blank is made of the following raw materials in parts by mass: 45 parts of kaolin, 32 parts of gneiss, 18 parts of rhodochrosite, 15 parts of orthoclase, and 5 parts of nano zirconium disilicide , 7 parts of red corundum, 5 parts of magnesite, 9 parts of mullite whiskers, 7 parts of yttria stabilized zirconia, 6 parts of carbon fiber, 15 parts of wheat straw powder, 6 parts of sawdust, 6 parts of corn flour, nano antibacterial powder 5 servings.

[0064] The glaze is made from the following raw materials in parts by mass: 16 parts of frit powder, 17 parts of potassium feldspar powder, 17 parts of silicon dioxide, 14 parts of lithium carbonate, and 12 parts of coloring material.

[0065] The frit is made of the following raw materials in parts by mass: 38 parts of silica, 13 parts of aluminate, Ni 2 o 3 9 parts, Al 2 o 3 8 parts, PbO7 parts, Mn 2 o 5 2 servings.

[0066] The prepar...

Embodiment 3

[0091] The basic process is the same as in Example 1, the difference is that the pottery blank is made of the following raw materials in parts by mass: 45 parts of kaolin, 25 parts of gneiss, 13 parts of rhodochrosite, 10 parts of orthoclase, and 8 parts of nano zirconium disilicide , 7 parts of red corundum, 4 parts of magnesite, 8 parts of mullite whiskers, 5 parts of yttria stabilized zirconia, 7 parts of carbon fiber, 16 parts of wheat straw powder, 6 parts of sawdust, 5 parts of corn flour, nano antibacterial powder 5 servings.

[0092] The glaze is prepared from the following raw materials in parts by mass: 14 parts of frit powder, 14 parts of potassium feldspar powder, 12 parts of silicon dioxide, 15 parts of lithium carbonate, and 13 parts of colorant.

[0093] The frit is made of the following raw materials in parts by mass: 35 parts of silica, 12 parts of aluminate, Ni 2 o 3 6 parts, Al 2 o 3 11 parts, PbO9 parts, Mn 2 o 5 3 copies.

[0094] The preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com