Equipment and method for alternately coating water on surface of dough of fried bread stick machine

A technology for machine noodles and fritters, which is applied in lighting and heating equipment, dough processing, baking, etc., can solve problems such as affecting the lamination effect and rise, low efficiency, disadvantage, etc., to achieve smooth compression motion, avoid jitter, Avoid shaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

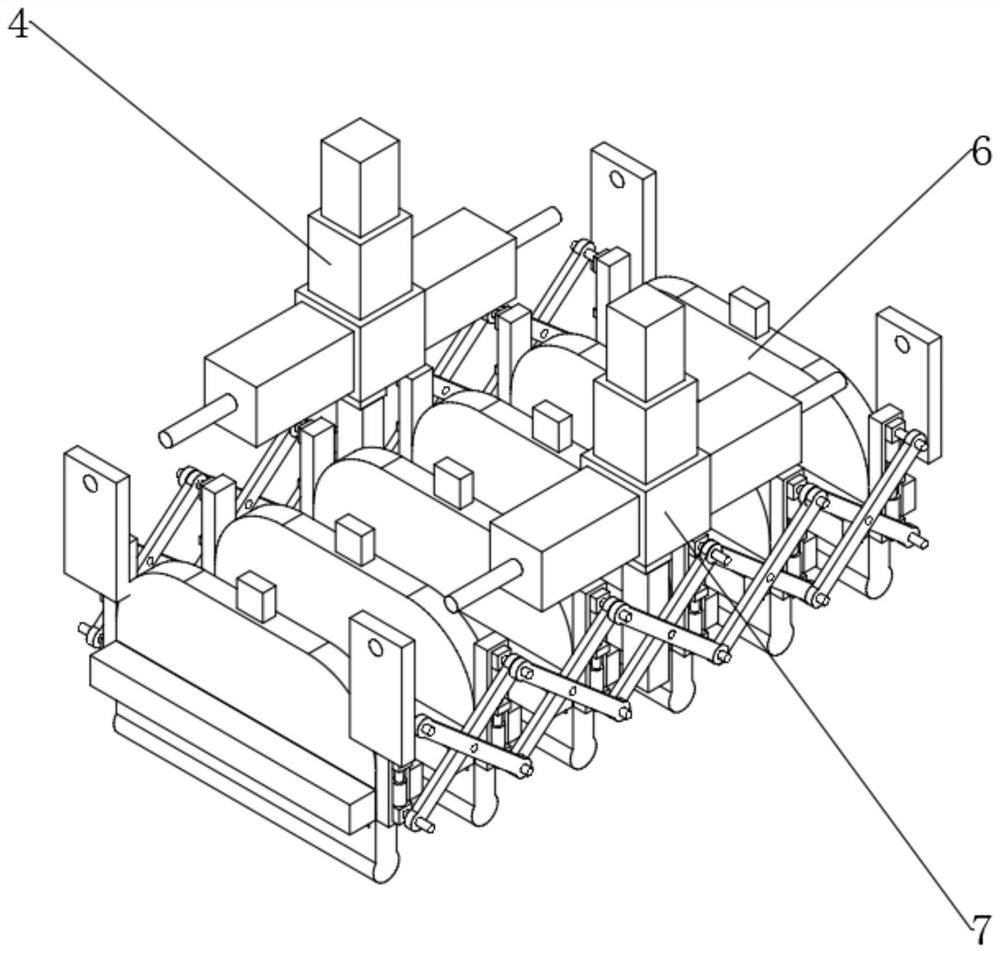

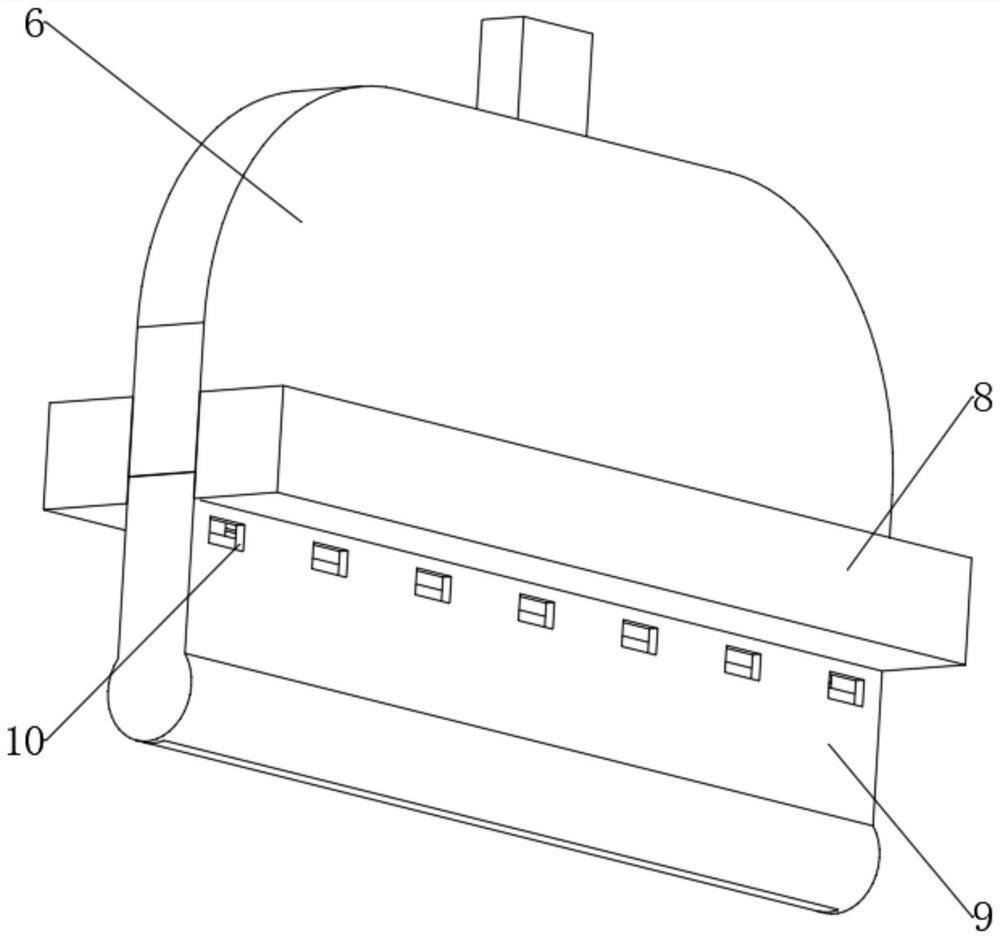

[0031] like Figure 1-Figure 8 As shown, the surface interval watering equipment of the fritter maker provided by the present embodiment includes a bottom plate 1 and a top frame 3 fixedly connected to its top outer wall. The rolling assembly between the two, the rolling assembly includes a cover 6 and a vertical plate 9 that is fixedly connected to its bottom outer wall. The bottom outer wall of the vertical plate 9 is set to a spherical shape, and the bottom outer wall of the vertical plate 9 is provided with a through groove, and the inner wall of the through groove is slidably connected. There is a plug plate 13, the top outer wall of the plug plate 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com