Direct pressing type steel seal coding machine

A coding machine, direct pressure technology, applied in printing, stamping, packaging and other directions, can solve the problems of high price, different code depths, and high maintenance costs, and achieve stable and reliable quality, reliable theoretical methods, and easy installation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

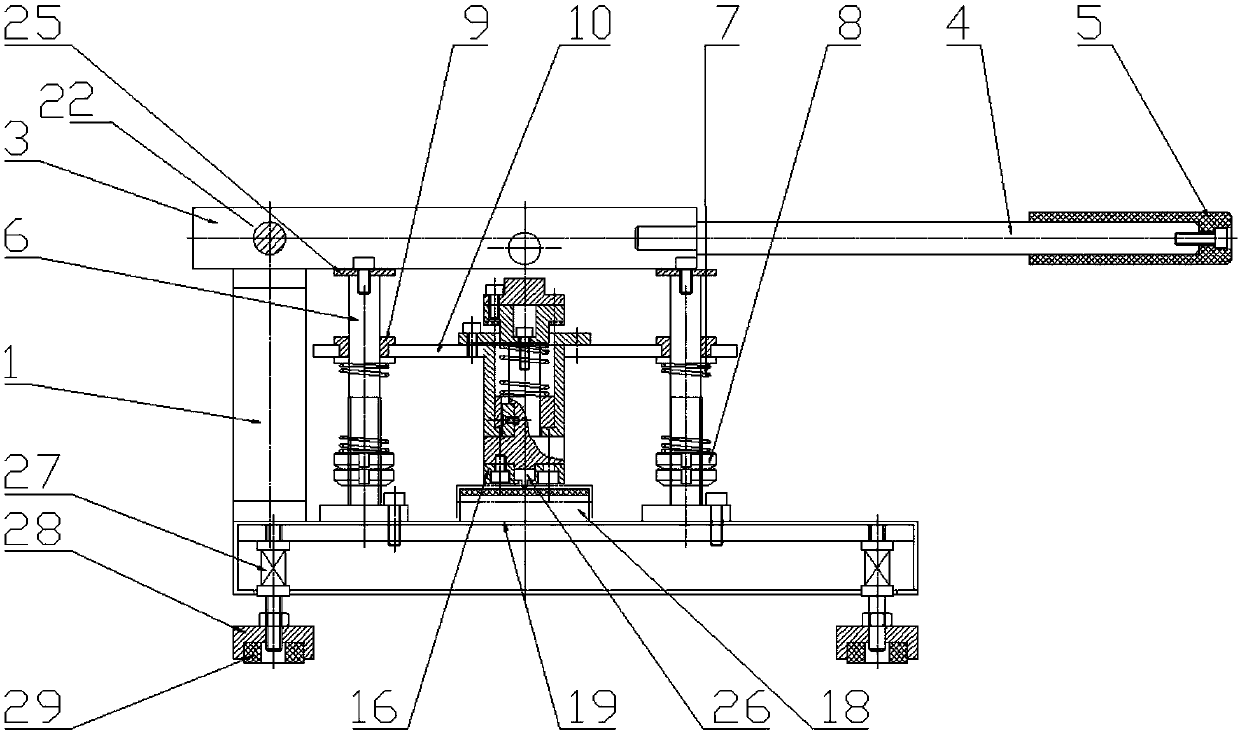

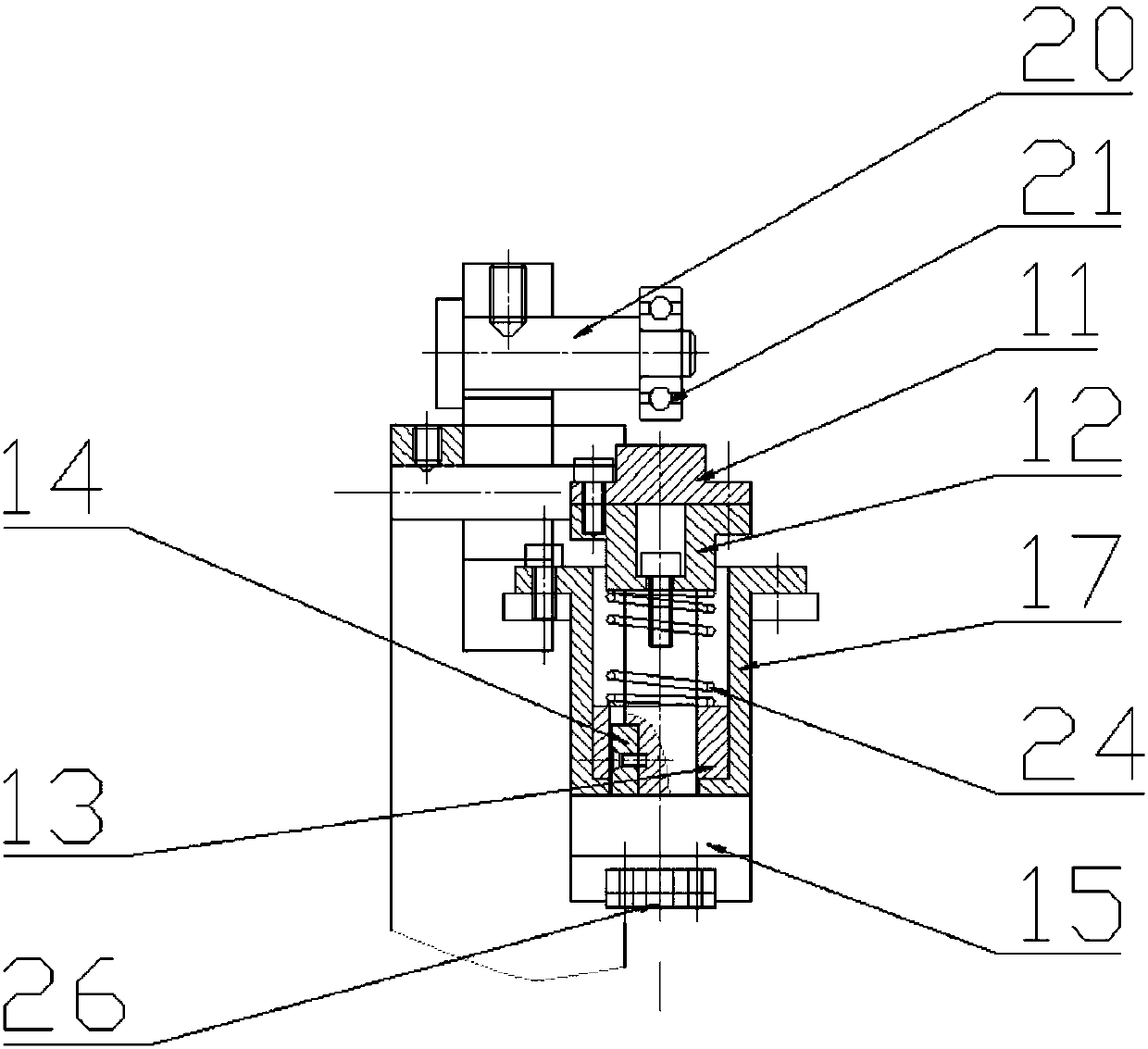

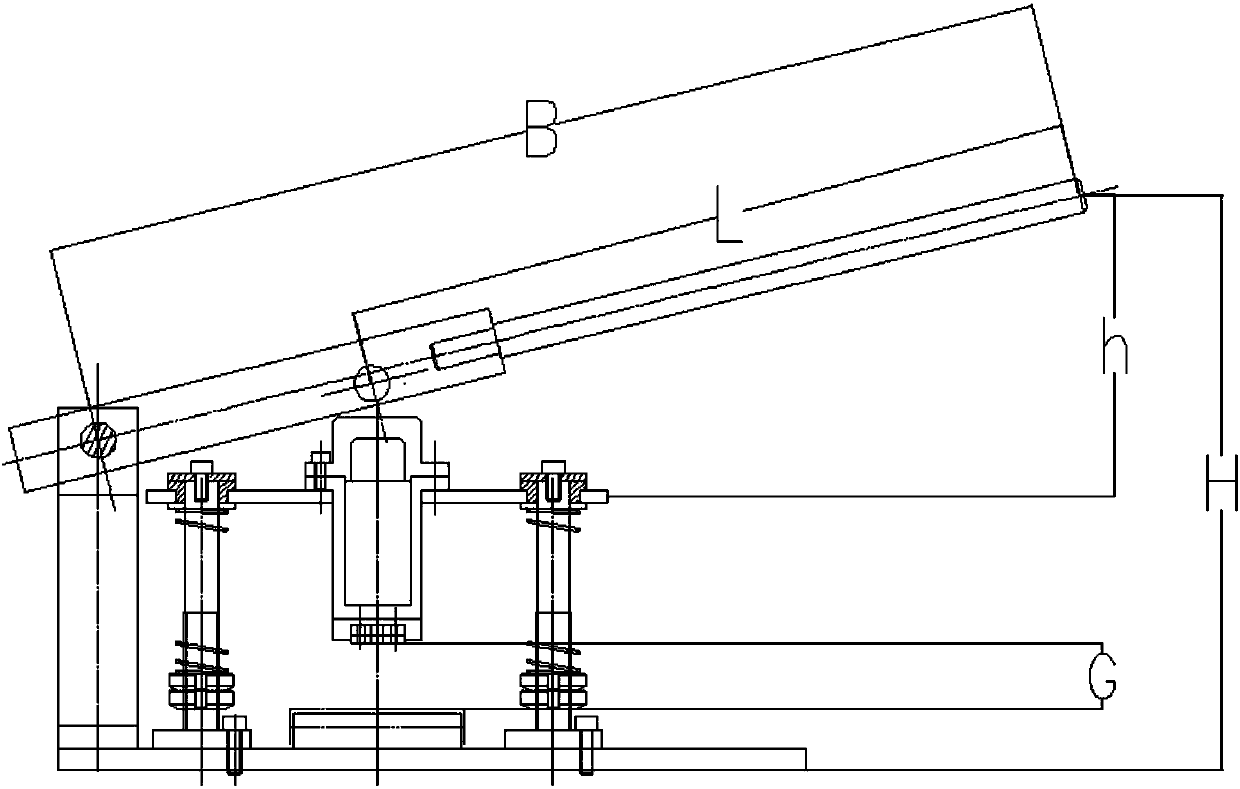

Embodiment 1

[0054] A direct-pressure steel stamp coding machine, which mainly consists of a base (19), a support (1), a handle bracket (3), a handle (4), a roller shaft (20), a bearing (21), a guide shaft (6 ), guide spring (7), nut (8), guide sleeve (9), pressure plate (10), sleeve (17), copper sleeve (13), spring (24), word code seat upper cover (11), Character code seat lower cover (12), character code seat (15), character code gland (16), small box positioning block (18) is formed, and support (1) is installed on base (19), and support (1) There is a card slot on the upper part, the handle bracket (3) is connected to the handle bracket (3) through the pin shaft (22) in the card slot, the handle bracket (3) can rotate freely around the pin shaft (22), and a round hole is opened on the front of the handle bracket (3) for The roller shaft (20) is passed through, and the finger moving screw is fixed, the bearing (21) is installed at the end of the roller shaft (20), the side end of the ha...

Embodiment 2

[0056] The difference from Example 1 is that the upper part of the support (1) is equipped with a limit block, and the upper part of the limit block is designed with a slope, which limits the handle bracket (3) to a large rotation in the working direction, and in the opposite direction of the working direction. Orientation cannot be rotated.

Embodiment 3

[0058] The difference from Example 1 is that the end of the handle bracket (3) is provided with a threaded hole, the handle (4) is installed on the handle bracket (3) through the top external thread, and the handle cover (5) is fixed on the handle (4) by screws Another top.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com