A cold and hot combination interference fit assembly method and LED lamps

A technology of LED lamps and assembly methods, which is applied to cooling/heating devices of lighting devices, headlights, manufacturing tools, etc., can solve the problems of wasting energy and resources, low interference tolerance rate, poor consistency, etc., and achieve energy saving, The effect of enhancing heat transfer capability and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

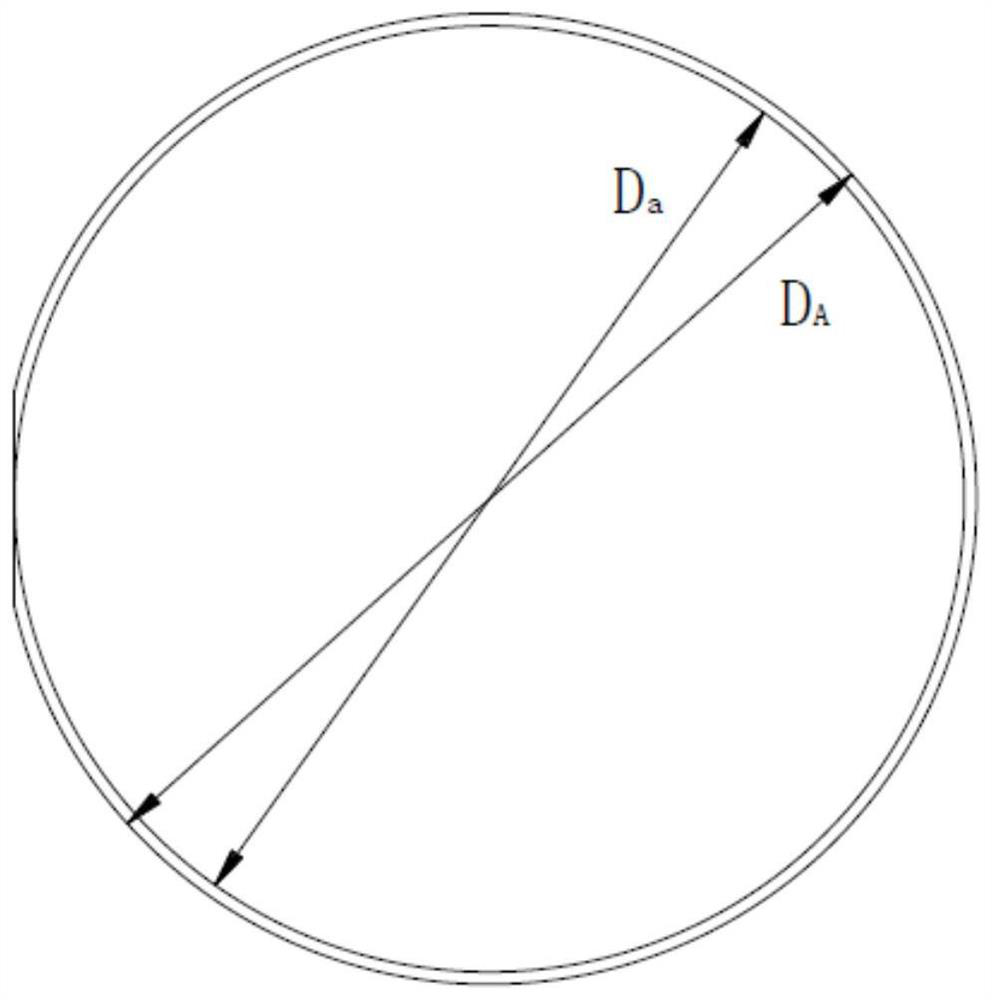

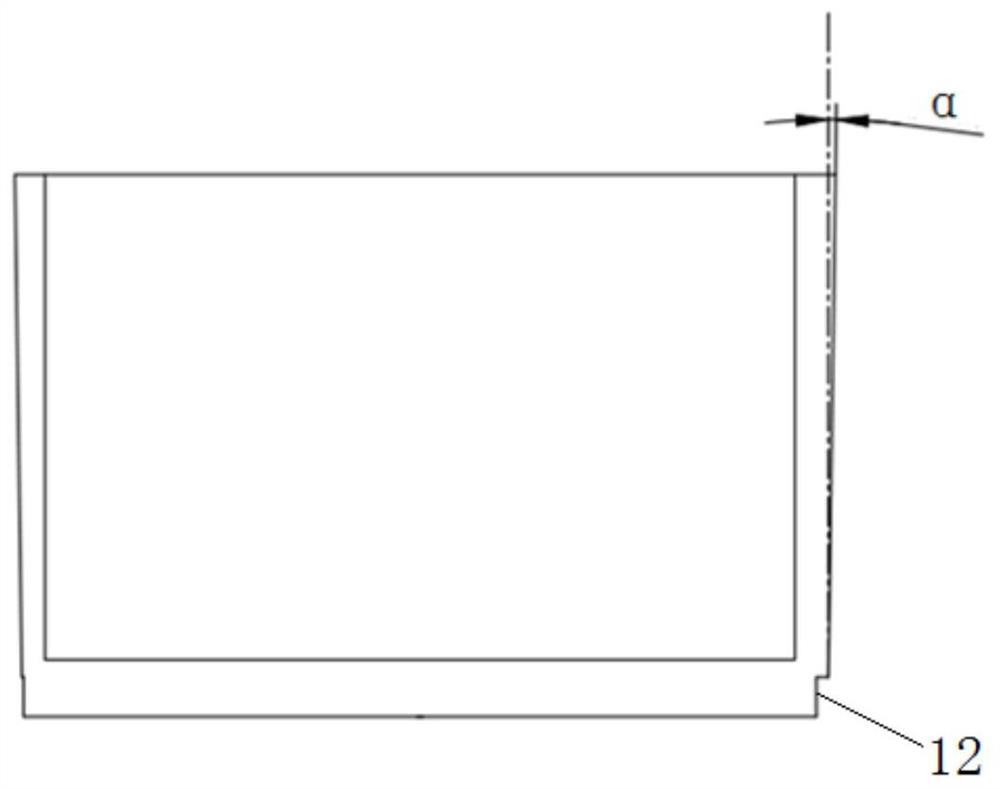

[0044] Such as Figure 1a , Figure 1b As shown, A die-casting 1 is cylindrical, its side is processed with an outer limit surface 11, and the bottom is processed with an outer limit ring 12; the draft angle α of A die-casting 1 is 0.8-5°; A die-casting 1 The bottom diameter is D A , the diameter of the outer limit ring 12 is D a ; A die casting 1 thermal expansion coefficient λ A It is 1E-6 / °C.

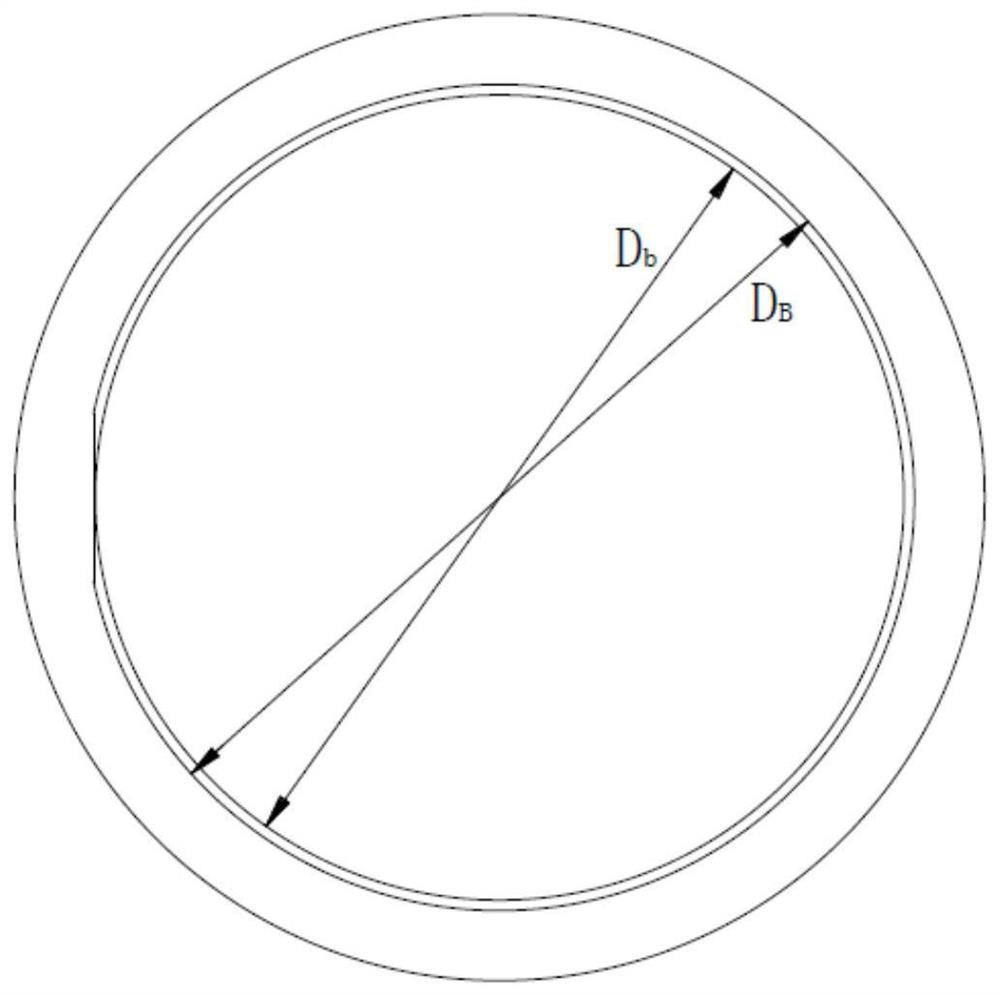

[0045] Such as Figure 2a , Figure 2b As shown, B die-casting 2 is cylindrical, its inner wall has an inner limiting surface 21, and the bottom has an inner limiting ring 22; the inner limiting surface 21 corresponds to the position and shape of the outer limiting surface 11 of A die-casting 1 , the position and shape of the inner limit ring 22 correspond to the outer limit ring 12; the inner diameter of the bottom of the B die-casting part 2 is D B , the diameter of the inner limit ring 22 is D b . D. a >D b , (D A -D a )>Tλ B D. B ,D B -D b =D A -D a ,D B ×(1+Tλ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com