Magnetic cyclodextrin-based chelated decolorization adsorption material and preparation method thereof

An adsorption material, cyclodextrin technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of difficult elution and regeneration, high manufacturing cost, small adsorption capacity, etc. Layer uniformity, reduce interference, achieve the effect of structure and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

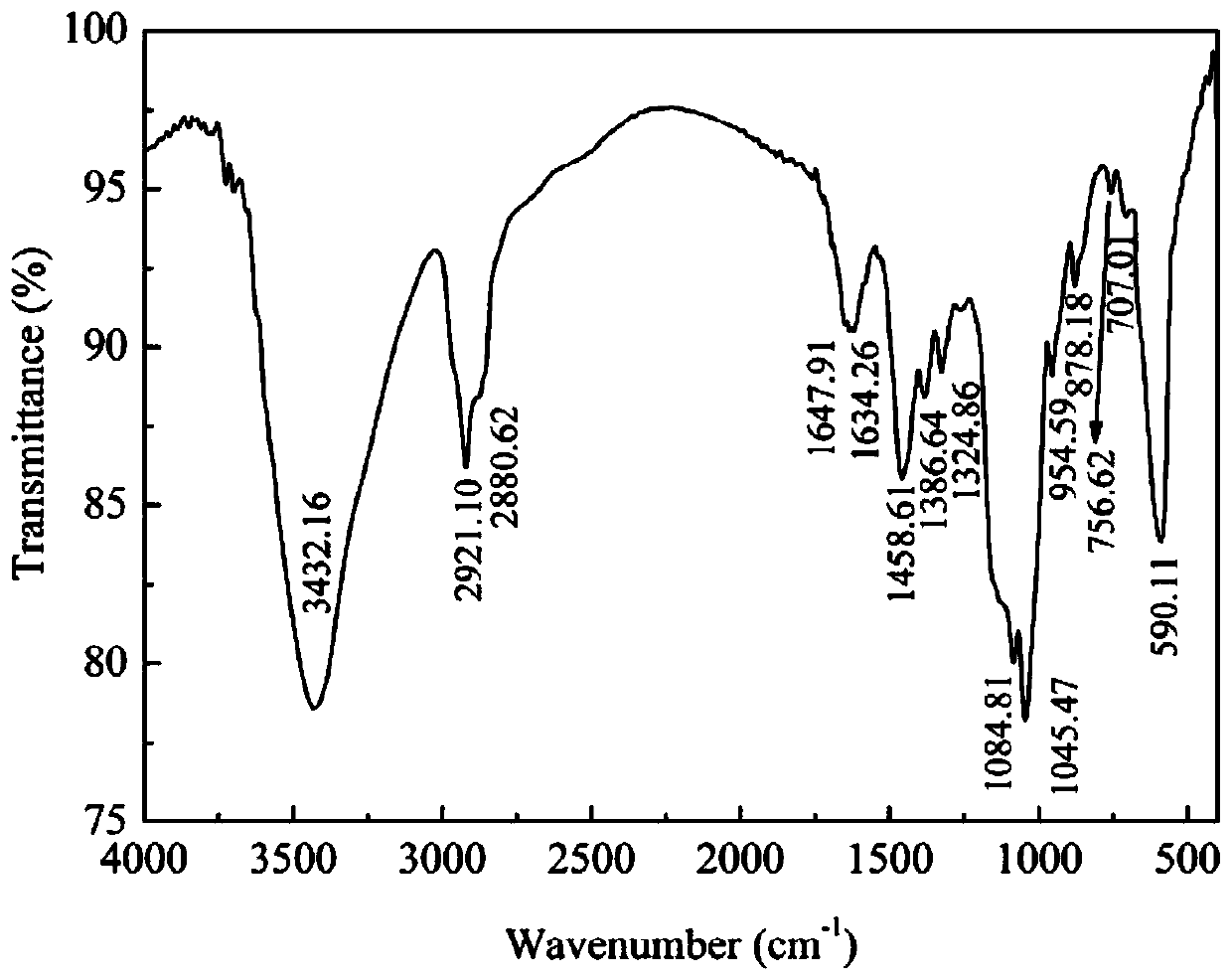

Image

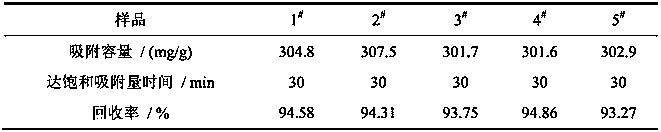

Examples

Embodiment 1

[0036] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 5.54 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensing device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 15%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:30, and 1.08 g of sodium hydroxide with a mass fraction of 96% is added to a three-necked flask for dissolution ;

[0037] (2) In the solution of step (1), add 0.50 g of ferric oxide microspheres according to the mass ratio of β-cyclodextrin and ferric oxide microspheres to 1:0.5, and stir for 30 minutes with ultrasonic assistance;

[0038] (3) Add 22.18mL of liquid paraffin and 1.48g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:4, the mass volume ratio of the emulsifier to the oil phase is 1:15g / mL, and ultrasonic After auxiliary stirring for 30 min...

Embodiment 2

[0042] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 3.91 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensation device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 20%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:40, and 1.44g of mass fraction of 96% sodium hydroxide is added into a three-necked flask for dissolution ;

[0043] (2) In the solution of step (1), add 1.00 g of ferric oxide microspheres according to the mass ratio of β-cyclodextrin and ferric oxide microspheres as 1:1, and ultrasonically assisted stirring for 40 min;

[0044] (3) Add 23.45mL of liquid paraffin and 1.56g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:6, the mass volume ratio of the emulsifier to the oil phase is 1:15g / mL, and ultrasonic After auxiliary stirring for 30 minutes, the...

Embodiment 3

[0048] (1) Add 1.00 g of β-cyclodextrin with a mass fraction of 98% and 3.91 mL of deionized water into a 100 mL three-necked flask equipped with a constant pressure dropping funnel, a mechanical stirrer and a condensation device to form a β-cyclodextrin The mass percent concentration of dextrin is a solution of 20%, and the molar ratio of β-cyclodextrin and sodium hydroxide is 1:50, and 1.80 g of sodium hydroxide with a mass fraction of 96% is added to a three-necked flask for dissolution ;

[0049] (2) Add 1.50 g of ferric oxide microspheres into the solution in step (1) according to the mass ratio of β-cyclodextrin and ferric oxide microspheres to 1:1.5, and ultrasonically assisted stirring for 60 min;

[0050] (3) Add 31.26mL of liquid paraffin and 1.56g of Span-80 to the solution in step (2), the volume ratio of the water phase to the oil phase is 1:8, the mass volume ratio of the emulsifier to the oil phase is 1:20g / mL, and ultrasonic After auxiliary stirring for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com