Wiper speed regulation control method and system and speed regulation controller

A control method and technology of a control system, which are applied in the direction of a single motor speed/torque control, vehicle cleaning, vehicle maintenance, etc., can solve problems such as difficulty in adjusting the reverse speed of the wiper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

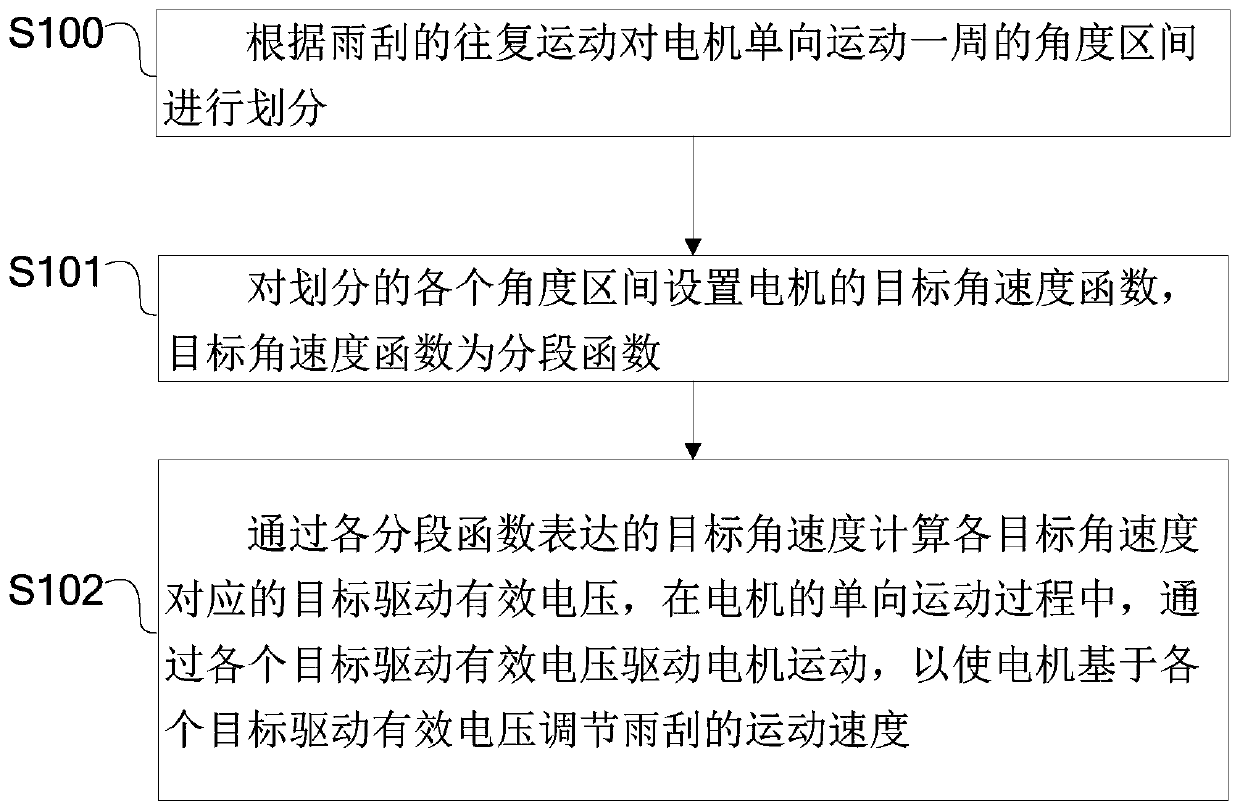

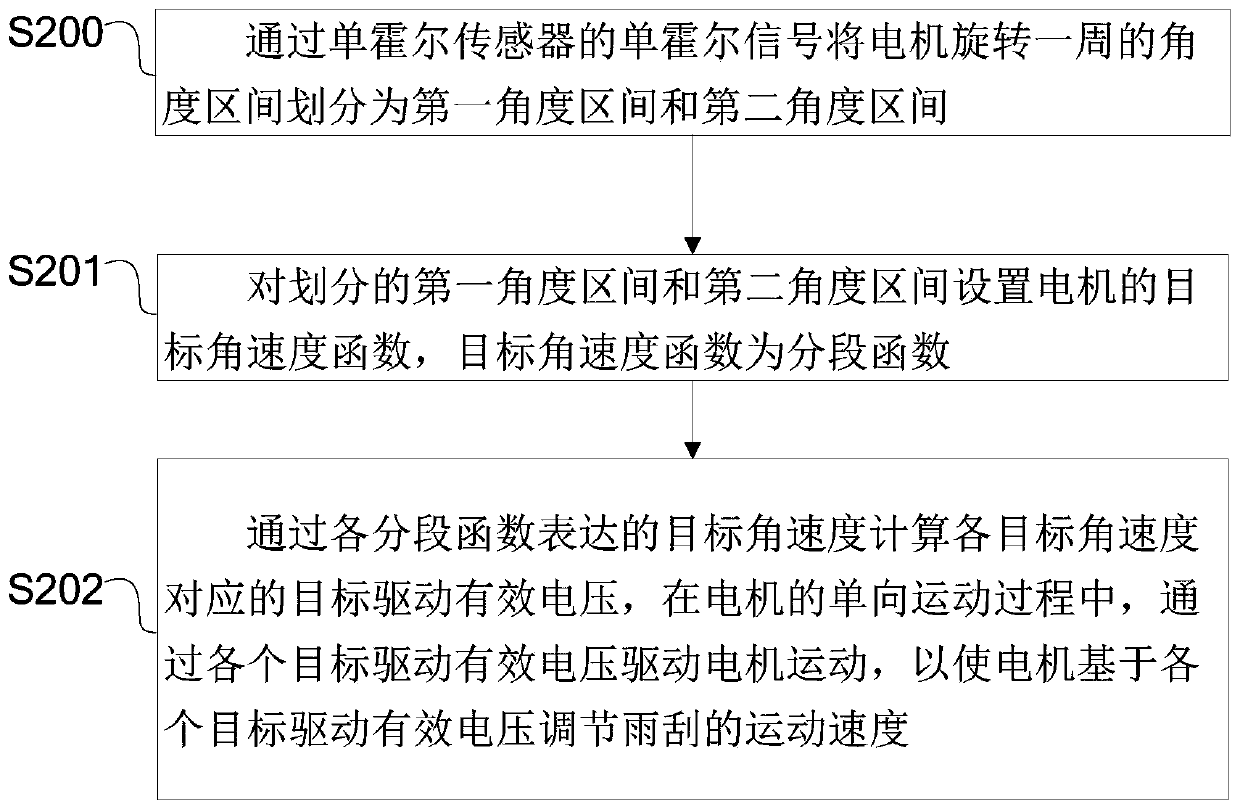

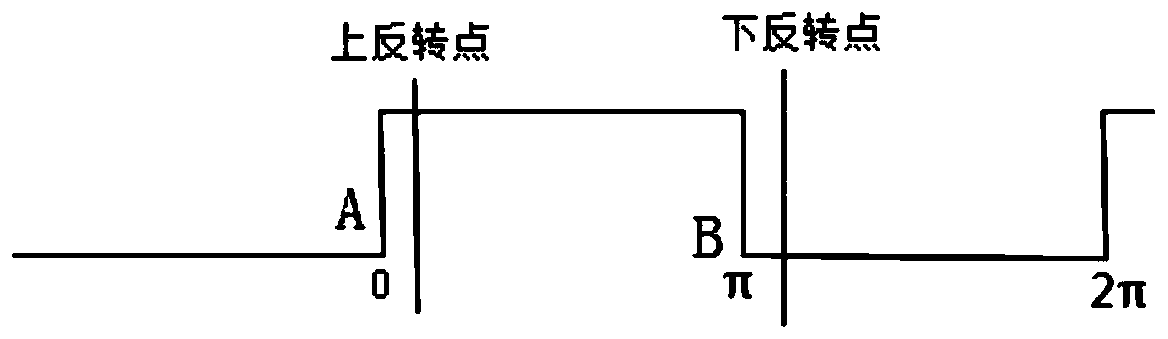

[0036] For the above application scenarios, this example provides a speed control method for wipers. The design idea of this method is: convert the one-way motion of the motor into the reciprocating motion of the wiper, and control the motor during the one-way motion of the motor The target drive effective voltage, so that the motor adjusts the movement speed of the wiper based on the target drive effective voltage.

[0037] Through the above-mentioned design idea, in the process of driving the wiper to and fro by the motor in one direction, the driving effective voltage of the motor is controlled, and then the variable speed movement of the wiper is controlled, for example, the wiper can be slowed down near the reversal point, The middle area controls the accelerated operation of the wiper in a certain way to increase the wiping speed, so as to ensure that the running speed of the wiper can be adjusted in the entire wiping cycle, reduce the elastic deformation of the wiper b...

Embodiment 2

[0065] Based on Embodiment 1, this example provides a wiper speed control system, the control principle of which is Figure 5 As shown, the schematic diagram of the circuit is shown in Figure 6 shown.

[0066] Including motor, induction module and control module, wherein, the motor is connected with the wiper through the connecting rod structure, and the one-way motion of the motor is converted into the reciprocating motion of the wiper through the connecting rod structure. Regarding the connecting rod between the motor and the wiper The structure and the reciprocating movement of the wiper are well known to those skilled in the art, and will not be described in detail in this example.

[0067] The induction module is installed in conjunction with the motor, and the induction module is used to sense two sets of signals according to the one-way movement of the motor;

[0068] The control module is electrically connected to the motor, and the control module performs the follo...

Embodiment 3

[0103] Based on the first and second embodiments, this example provides a wiper speed control controller, including a control module and a sensing module. Wherein, the structure of the control module is the same as that of the control module in the second embodiment, and the structure of the sensing module is the same as that of the sensing module in the second embodiment. The specific structures of the control module and the sensing module will not be repeated in this example.

[0104] The induction module is installed with the motor, and the induction module is used to sense two sets of signals according to the one-way movement of the motor;

[0105] The control module is electrically connected to the motor, and the control module performs the following operations to control the target driving effective voltage of the motor, so that the motor can adjust the moving speed of the wiper based on the target driving effective voltage:

[0106] Divide the angle interval of one revo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com