Circuit overload protection and replacement protection method

A circuit and fuse technology, applied in the field of circuit protectors, to achieve the effect of improving convenience, simple principle and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

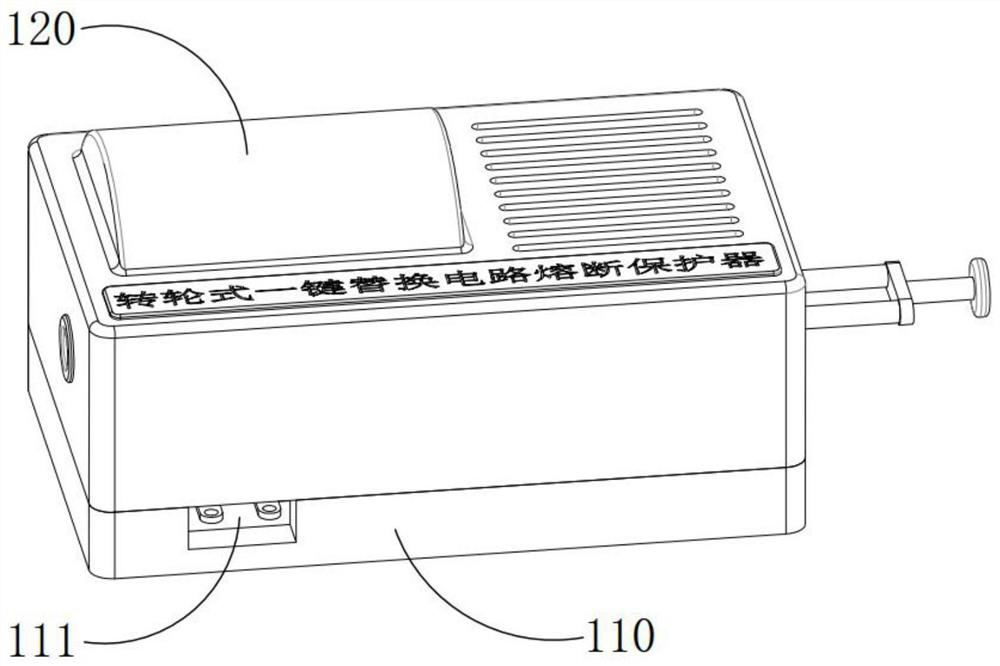

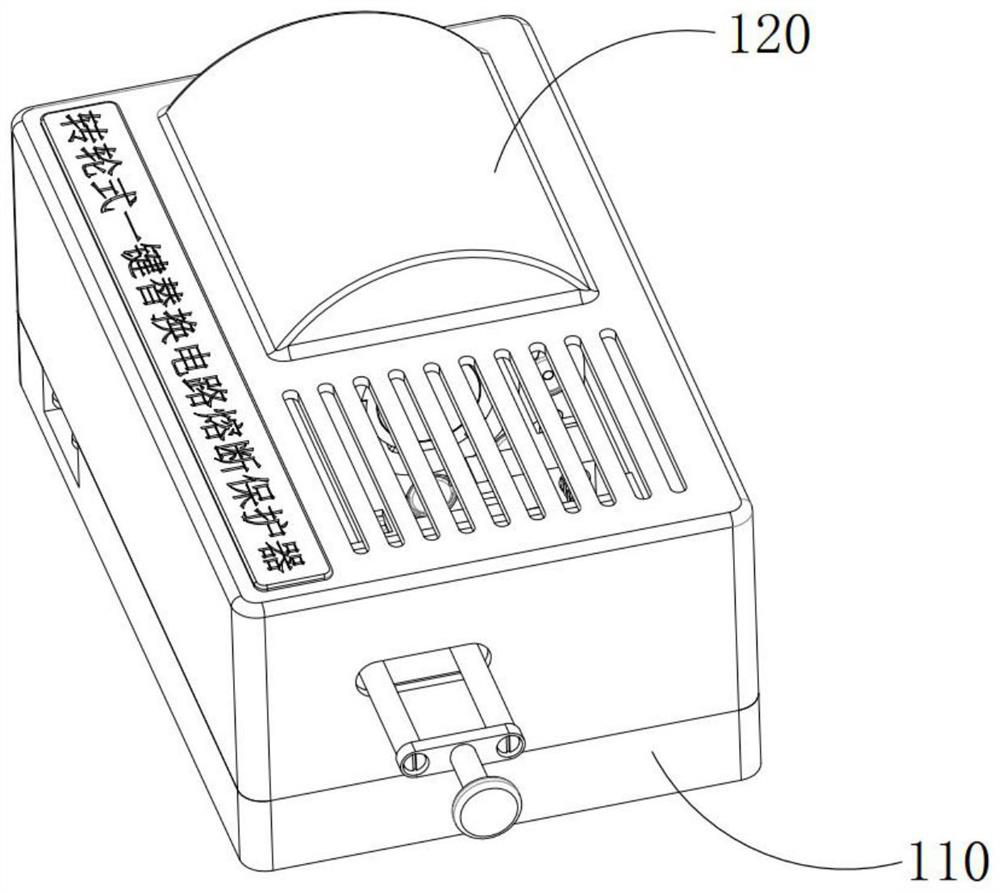

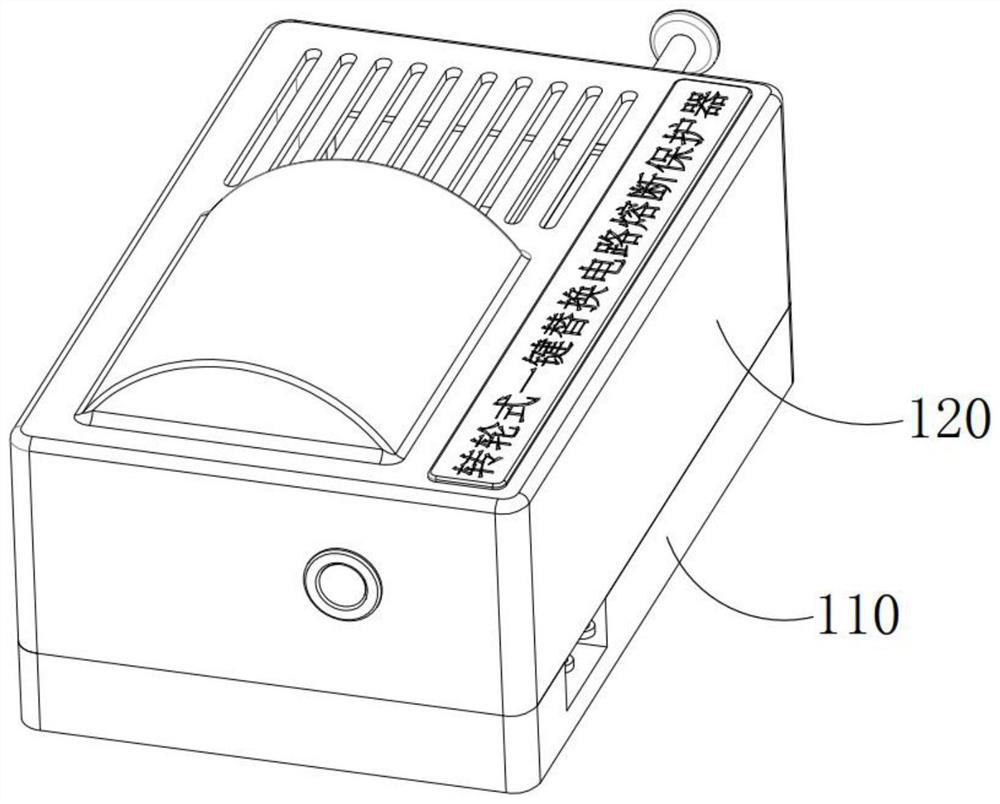

Image

Examples

Embodiment Construction

[0070] The overload protection of the circuit and the method for replacement protection, the steps are as follows:

[0071] (1) Fuse protection stage;

[0072] S1: When the circuit current increases abnormally, the safety tube assembly in the rotation insurance mechanism 220 connected in series with the docking mechanism 210 will fuse, the input end and the output end of the docking mechanism 210 will be disconnected, and the live wire circuit will be disconnected for self-protection;

[0073] The docking mechanism 210 includes a vertical plate 211 arranged at one end of the bottom plate 110 along the length direction. The vertical plate 211 is arranged along the width direction of the bottom plate 110. An insulating docking plate 212 is fixedly installed on the vertical plate 211. The docking plate 212 The axial direction of the butt plate 110 is parallel to the length direction of the bottom plate 110, and the end surface of the docking plate 212 close to the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com