Full-automatic optical detection system for chip detection

A technology of optical detection and chip detection, which is applied in the direction of material analysis, measuring devices, scientific instruments, etc. through optical means, and can solve problems such as inadequacy and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

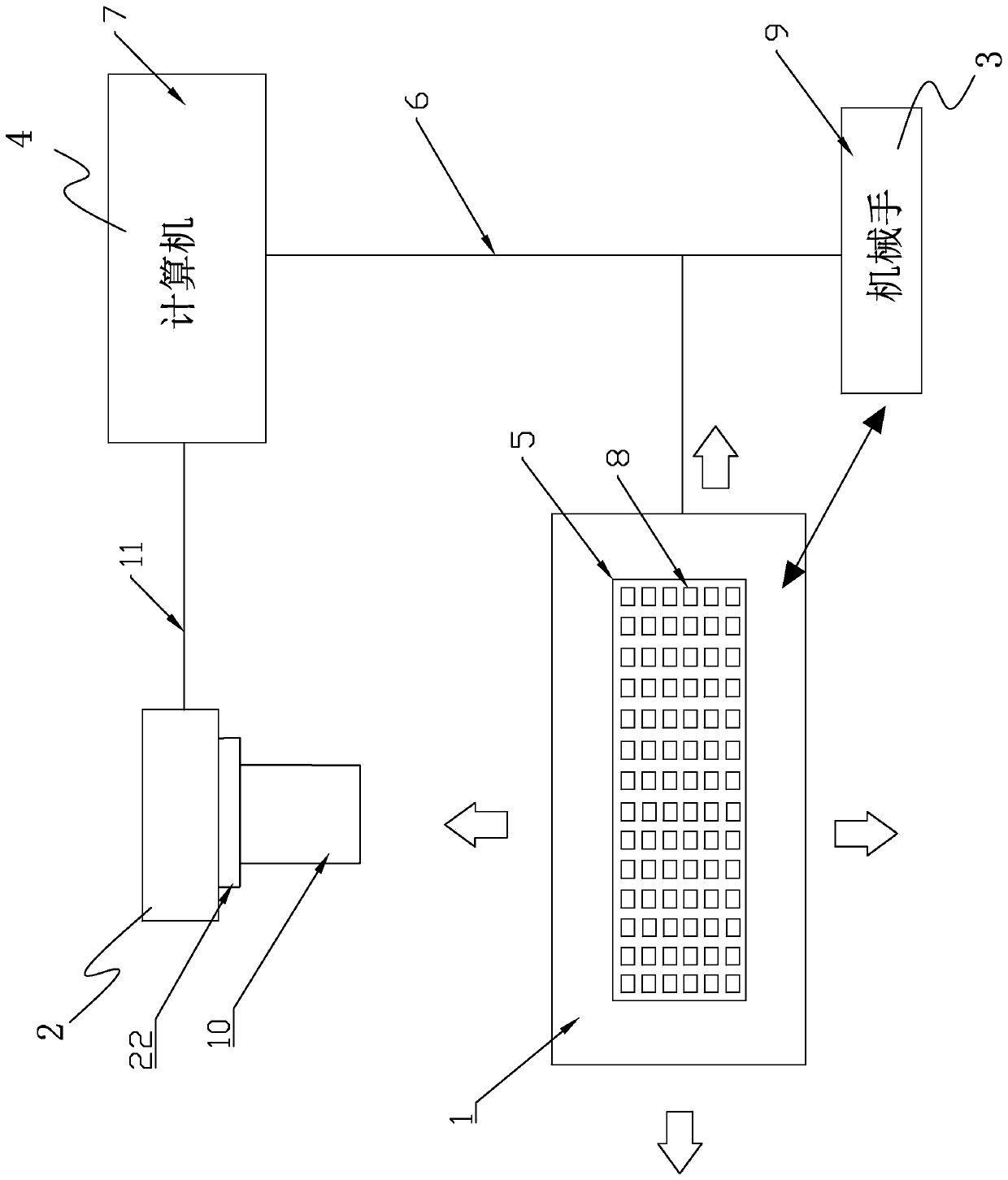

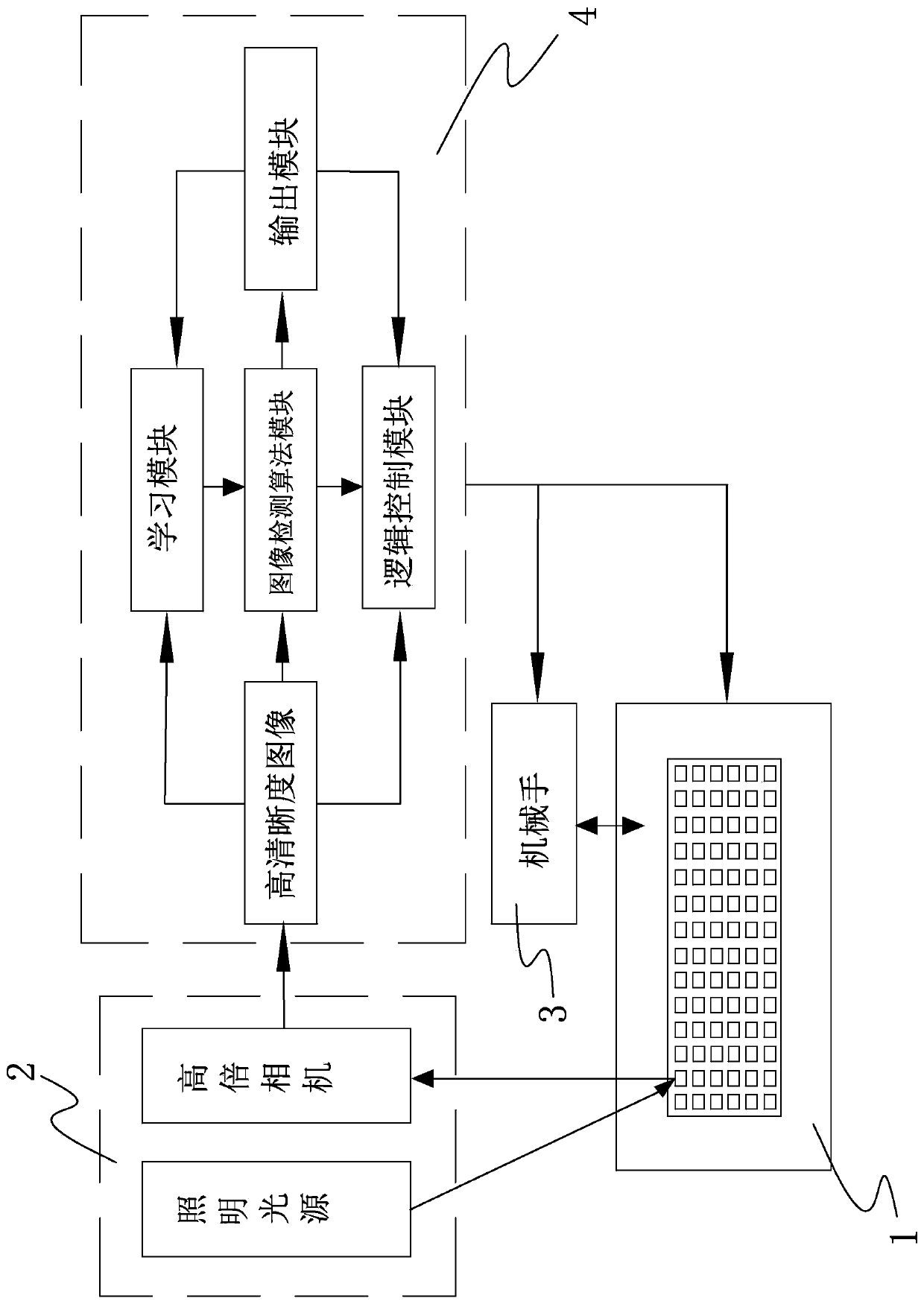

[0032] Such as Figures 1 to 2 A fully automatic optical detection system for chip detection is shown, including:

[0033] The stage 1 is used to place the chip 5 and can move in any direction to realize the path planning of the detection, and accurately and quickly detect each chip 8;

[0034] The loading and unloading device 3 is used to grab the chips to be inspected, place the chips to be inspected on the stage 1 or remove them from the stage 1, the loading and unloading device 3 is arranged on one side of the stage 1, and the The loading and unloading device 3 is a manipulator 9;

[0035] Acquisition device 2 is used to obtain chip image information on the stage 1. The acquisition device 2 is arranged above the object stage 1. The acquisition device 2 is a high-power camera 10. The acquisition device 2 is provided with a device cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com