Thermoelectric refrigeration artificial formation freezer

A technology of thermoelectric refrigeration and freezer, which is applied in infrastructure engineering, soil protection, construction, etc. It can solve the problems of easy pollution caused by leakage, easy breakage of freezing tubes, and high construction costs, so as to save refrigeration and maintenance costs and shorten melting The effect of shortening the time and shortening the digging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

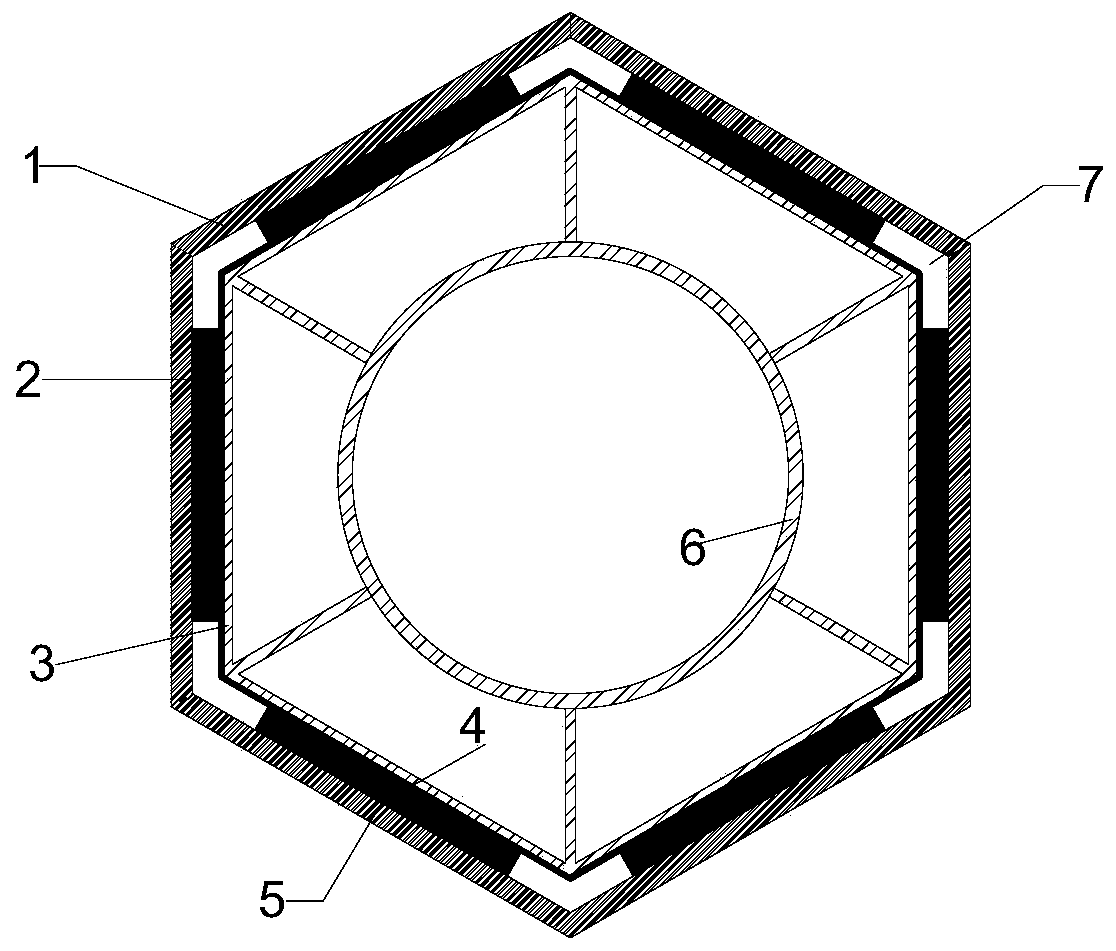

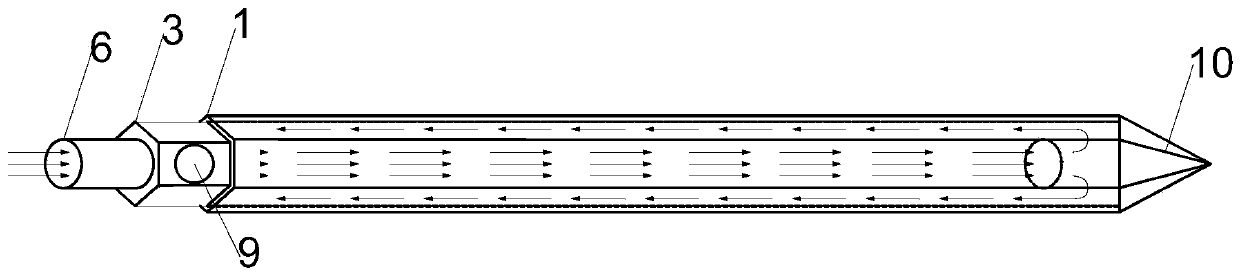

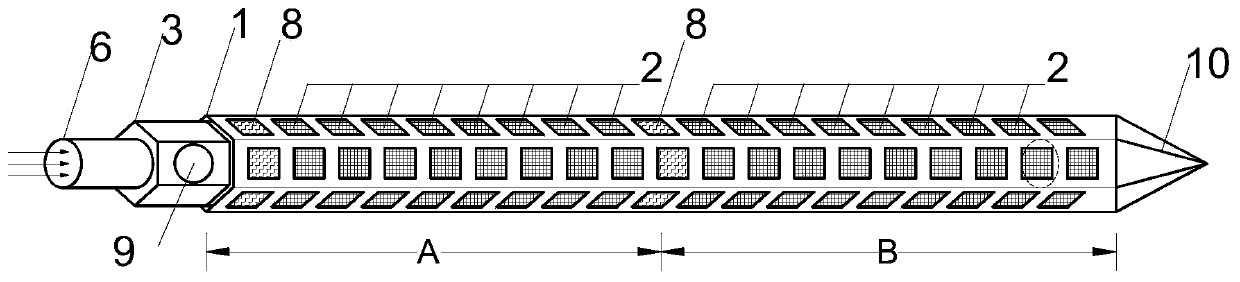

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-3 Shown is a thermoelectric refrigeration artificial formation freezer provided by the present invention, which can not only be used for artificial formation freezing, but also for freezing other frozen bodies. It includes a protection device, a solid-state refrigeration device, a heat dissipation device and a control unit 8, the heat dissipation device is arranged in the protection device, the solid-state refrigeration device is arranged between the protection device and the heat dissipation device, and is closely attached to the protection device and the heat dissipation device, and the control unit 8 Used to control the circuit, current magnitude and direction of a solid-state refrigeration unit. A temperature sensor 14 for detecting the temperature of the protection device and the heat sink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com