Soil conditioner and preparation method thereof

The technology of soil conditioner and binder is applied in the field of soil conditioner and its preparation to achieve the effects of promoting crop growth, killing or repelling pests, and increasing soil organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

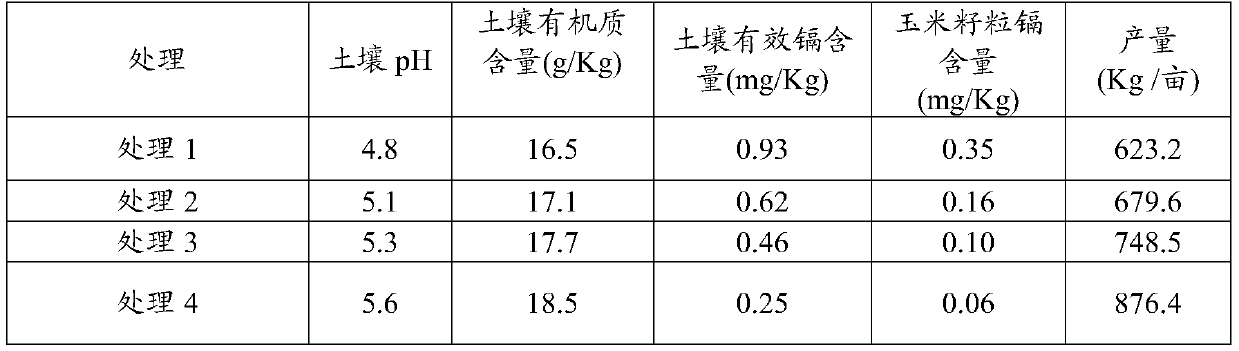

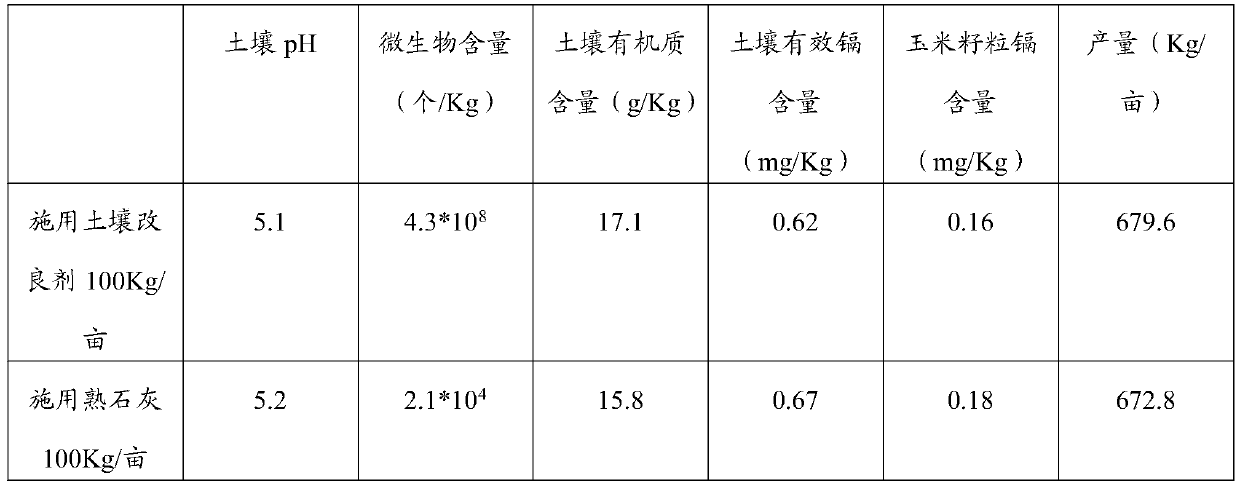

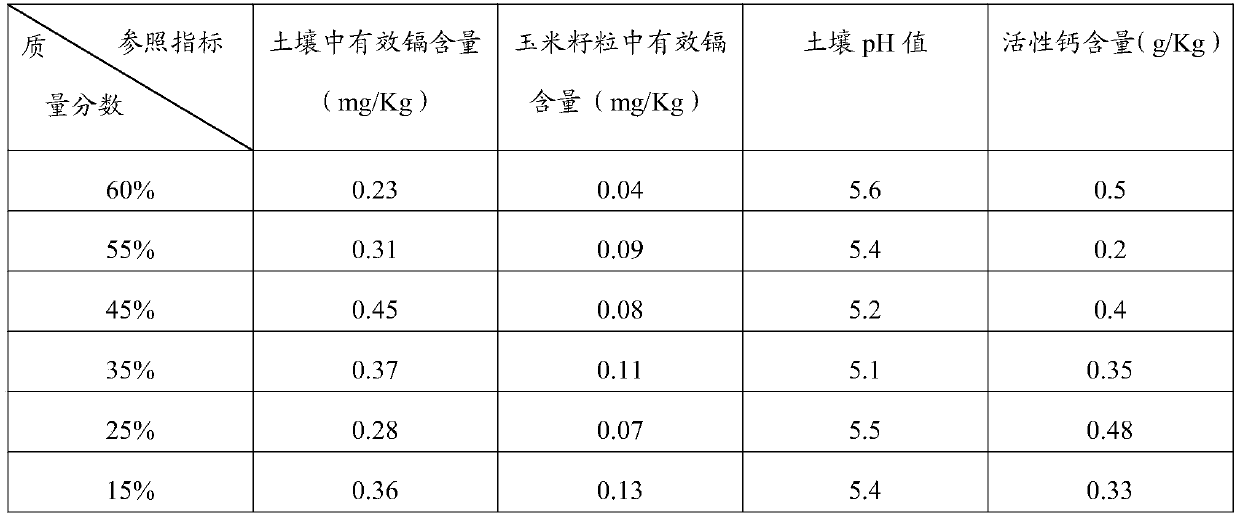

Examples

Embodiment 1

[0030] The embodiment of the present invention discloses a soil conditioner, which is composed of the following raw materials with the optimal weight ratio: 60% of biochar, 16% of wood acetic acid, 22% of shell powder, 0.3% of borax, 0.3% of zinc sulfate, Magnesium sulfate 0.3%, ammonium molybdate 0.1% and binder 1.0%.

[0031] The preparation method of soil conditioner is:

[0032] 1) Weighing raw materials: weighing biochar, wood acetic acid, shell powder, borax, zinc sulfate, magnesium sulfate, ammonium molybdate and binder according to the weight ratio.

[0033] 2) Mixing: crush the biochar through a 40-mesh sieve; crush the shells through a 60-mesh sieve; mix and pulverize the borax, zinc sulfate, magnesium sulfate and ammonium molybdate, and pass through a 40-mesh sieve for later use; Mix evenly with wood acetic acid to obtain a mixture;

[0034] 3) Gelatinization: Add appropriate amount of water into the gelatinization tank, add starch adhesive while stirring, and adj...

Embodiment 2

[0053] A soil improver, which is composed of the following raw materials in parts by weight: 58.25% of biochar, 17% of wood acetic acid, 23% of shell powder, 0.4% of borax, 0.2% of zinc sulfate, 0.2% of magnesium sulfate, and 0.05% of ammonium molybdate % and binder 0.9%, the pH value of the soil conditioner is 7.

[0054] The preparation method of soil conditioner is:

[0055] 1) Weighing raw materials: weighing biochar, wood acetic acid, shell powder, borax, zinc sulfate, magnesium sulfate, ammonium molybdate and binder according to the weight ratio.

[0056] 2) Mixing: crush the biochar through a 50-mesh sieve; crush the shells through a 70-mesh sieve; mix and pulverize borax, zinc sulfate, magnesium sulfate and ammonium molybdate, and pass through a 50-mesh sieve for later use; Mix evenly to obtain a mixture;

[0057] 3) Gelatinization: Add appropriate amount of water into the gelatinization tank, add starch adhesive while stirring, and adjust the starch adhesive to a st...

Embodiment 3

[0077] A soil improver, which is composed of the following raw materials in proportion by weight: 62% of biochar, 15% of wood acetic acid, 21% of shell powder, 0.2% of borax, 0.4% of zinc sulfate, 0.2% of magnesium sulfate, and 0.2% of ammonium molybdate % and binder 1%, the pH of the soil conditioner is 10.0.

[0078] 1) Weighing raw materials: weighing biochar, wood acetic acid, shell powder, borax, zinc sulfate, magnesium sulfate, ammonium molybdate and binder according to the weight ratio.

[0079] 2) Mixing: crush the biochar through a 60-mesh sieve; crush the shells through a 100-mesh sieve; mix and grind the borax, zinc sulfate, magnesium sulfate and ammonium molybdate evenly, and pass through a 60-mesh sieve for later use; Mix evenly to obtain a mixture;

[0080] 3) Gelatinization: add an appropriate amount of water to the gelatinization tank, add starch adhesive while stirring, and adjust the starch adhesive to a starch adhesive suspension with a concentration of 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com