Micro-fine particle high-silicon tailings grouting material

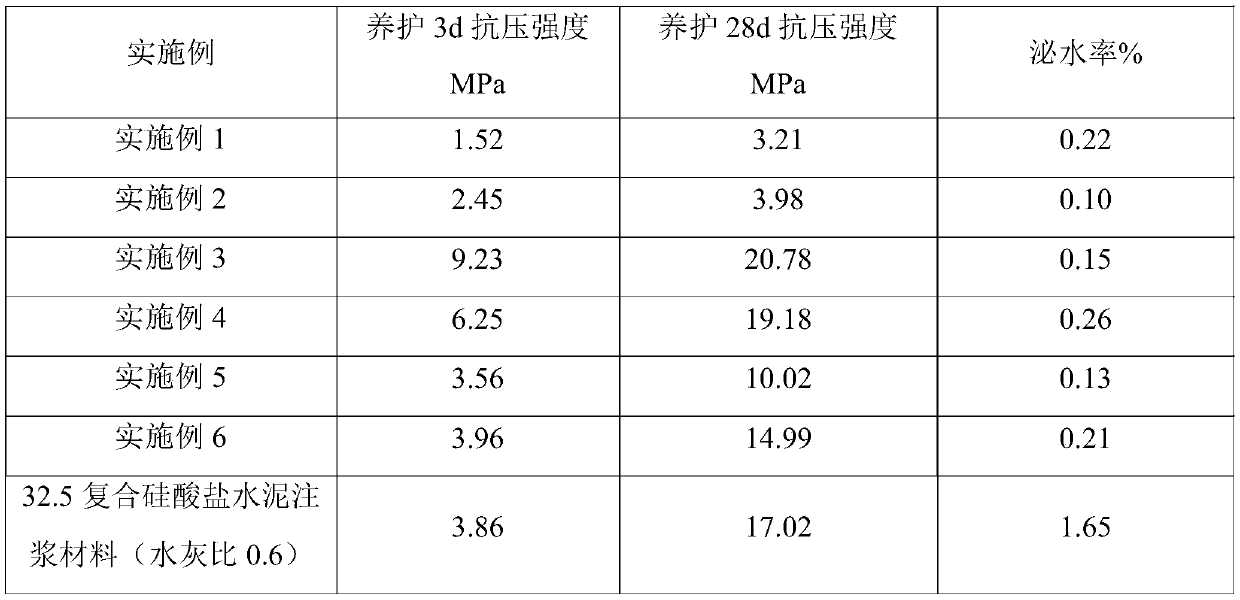

A technology of grouting materials and fine particles, which is applied in the field of grouting materials, can solve the problems of high pollution, poor slurry stability, and high cost, and achieve the effects of good slurry stability, high compressive strength, and low bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A microfine-grained high-silicon tailings grouting material is prepared by mixing the following raw materials in parts by weight: 90 parts of high-silicon tailings, 7 parts of lime, 3 parts of gypsum, 1 part of calcium chloride and 60 parts of water.

[0020] The high-silicon tailings are ground by a planetary ball mill, the grinding time is 40 minutes, and the corresponding specific surface area is 650m 2 / kg.

[0021] After mixing the raw materials in parts by weight, they are evenly stirred to obtain the fine-grained high-silicon tailings grouting material.

Embodiment 2

[0023] A grouting material for fine-grained high-silicon tailings, which is prepared by mixing the following raw materials in parts by weight: 90 parts of high-silicon tailings, 5 parts of lime, 2 parts of gypsum, 3 parts of calcium chloride and 60 parts of water.

[0024] The high-silicon tailings are ground by a planetary ball mill, the grinding time is 40 minutes, and the corresponding specific surface area is 650m 2 / kg.

[0025] After mixing the raw materials in parts by weight, they are evenly stirred to obtain the fine-grained high-silicon tailings grouting material.

Embodiment 3

[0027] A fine-grained high-silicon tailings grouting material, which is made by mixing the following raw materials in parts by weight: 50 parts of high-silicon tailings, 5 parts of lime, 4 parts of gypsum, 2 parts of calcium chloride, and 40 parts of granulated blast furnace slag and 60 parts of water.

[0028] The high-silicon tailings are ground by a planetary ball mill, the grinding time is 80 minutes, and the corresponding specific surface areas are 720m 2 / kg.

[0029] After mixing the raw materials in parts by weight, they are evenly stirred to obtain the fine-grained high-silicon tailings grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com