Method for preparing nanometer zinc oxide based on Lactobacillus casei secretion

A technology of Lactobacillus casei and nano-zinc oxide, which is applied in the field of preparing nano-zinc oxide, can solve the problems of low purity of nano-zinc oxide, and achieve the effects of low toxicity, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

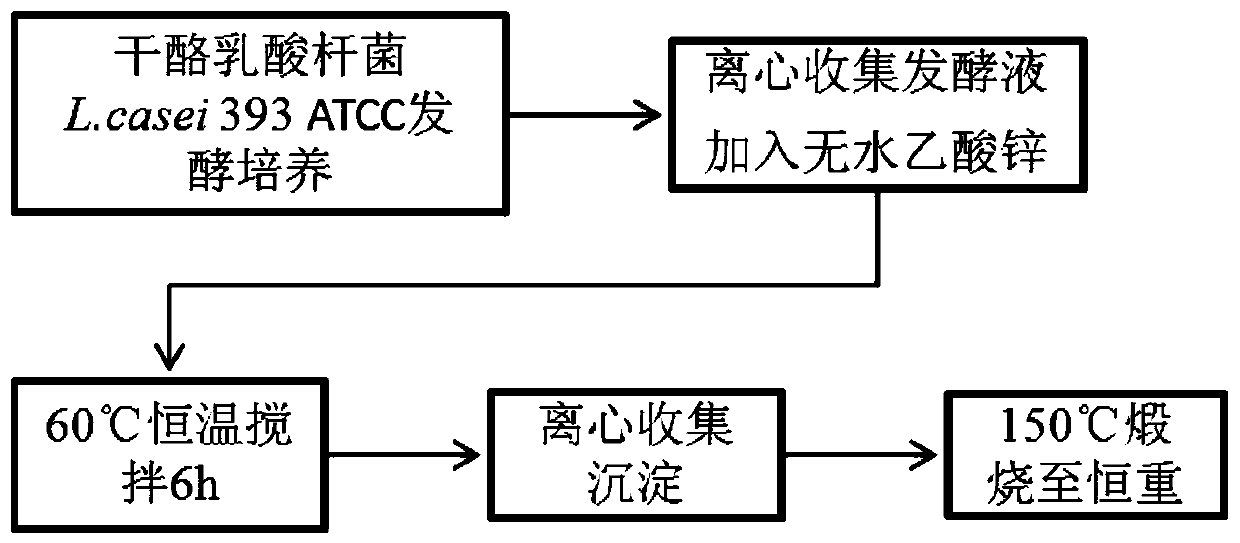

Method used

Image

Examples

Embodiment 1

[0018] Step 1. Strain activation:

[0019] Lactobacillus casei L.casei ATCC 393 strain was activated and cultured with MRS solid medium. The formula of MRS solid medium was as follows: peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, diammonium hydrogen citrate 2g / L L, glucose 20g / L, crystalline sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L, magnesium sulfate heptahydrate 0.6g / L, manganese sulfate monohydrate 0.25g / L, Tween 801mL / L, agar 15g / L , pH 6.4; L.casei ATCC 393 was inoculated in MRS solid medium by streaking, and cultured anaerobically at 37°C for 48h.

[0020] Step 2, biosynthesis of zinc hydroxide:

[0021] Cultivate the single colony of Lactobacillus casei L.casei ATCC 393 picked with MRS liquid medium. The formula of MRS liquid medium is as follows: peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, dihydrogen citrate Ammonium 2g / L, glucose 20g / L, crystalline sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L, magnesium sulfate heptahy...

Embodiment 2

[0032] Step 1. Strain activation:

[0033] Lactobacillus casei L.casei ATCC 393 strain was activated and cultured with MRS solid medium. The formula of MRS solid medium was as follows: peptone 11g / L, beef extract 11g / L, yeast extract 4g / L, diammonium hydrogen citrate 1.5g / L, glucose 23g / L, crystalline sodium acetate 4g / L, dipotassium hydrogen phosphate 2.3g / L, magnesium sulfate heptahydrate 0.5g / L, manganese sulfate monohydrate 0.27g / L, Tween 80 1.3mL / L, Agar 18g / L, pH 6.2; Streak inoculation of L.casei ATCC 393 on MRS solid medium, culture anaerobically at 35°C for 36h;

[0034] Step 2, biosynthesis of zinc hydroxide:

[0035] Cultivate the single colony of Lactobacillus casei L.casei ATCC 393 picked with MRS liquid medium, the formula of MRS liquid medium is as follows: peptone 11g / L, beef extract 11g / L, yeast extract 4g / L, dihydrogen citrate Ammonium 1.5g / L, glucose 23g / L, crystalline sodium acetate 4g / L, dipotassium hydrogen phosphate 2.3g / L, magnesium sulfate heptahydr...

Embodiment 3

[0039] Step 1. Strain activation:

[0040] Use MRS solid medium to activate Lactobacillus casei L.casei ATCC 393 strain. The formula of MRS solid medium is as follows: peptone 12g / L, beef extract 12g / L, yeast extract 6g / L, diammonium hydrogen citrate 2.5g / L, glucose 25g / L, crystalline sodium acetate 6g / L, dipotassium hydrogen phosphate 2.5g / L, magnesium sulfate heptahydrate 0.5g / L, manganese sulfate monohydrate 0.3g / L, Tween 80 1.5mL / L, Agar 20g / L, pH 6.6; Streak inoculation of L.casei ATCC 393 on MRS solid medium, culture anaerobically at 38°C for 42h;

[0041] Step 2, biosynthesis of zinc hydroxide:

[0042] Cultivate the single colony of Lactobacillus casei L.casei ATCC 393 picked with MRS liquid medium, the formula of MRS liquid medium is as follows: peptone 12g / L, beef extract 12g / L, yeast extract 6g / L, dihydrogen citrate Ammonium 2.5g / L, glucose 25g / L, crystalline sodium acetate 6g / L, dipotassium hydrogen phosphate 2.5g / L, magnesium sulfate heptahydrate 0.6g / L, manganes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com