Feed pressure assembly for ultrasonic plasticizing system

A component and feeding technology, applied in the field of feeding pressure components for ultrasonic plasticizing systems, can solve the problem of shortening the service life of the ultrasonic vibration system and the ultrasonic tool head, overheating and overloading of the ultrasonic vibration system, and wear of the barrel parts. Ultrasonic energy and other problems, to achieve the effect of reducing manual feeding time and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

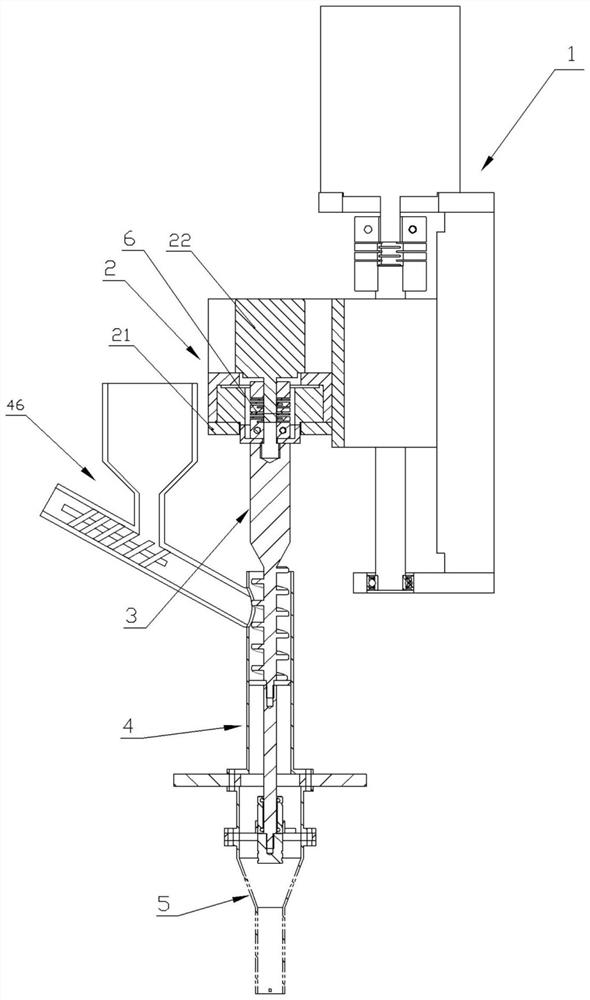

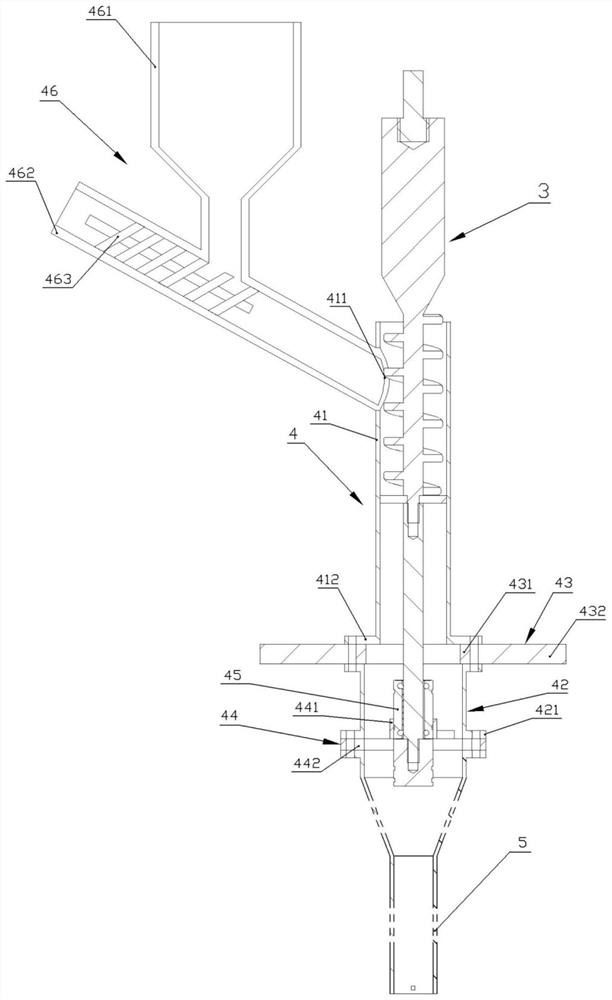

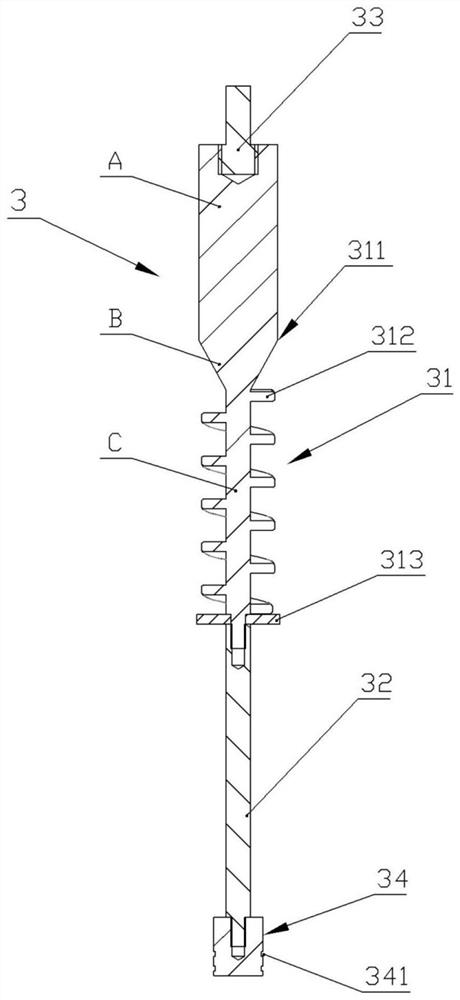

[0034] like figure 1 As shown, the ultrasonic plasticizing system provided by the present invention uses a feed pressure assembly, which includes a translation mechanism 1, a rotation mechanism 2, a feed pressure assembly 3 and a barrel assembly 4, wherein the translation mechanism 1 is a wire The bar slide table, the rotating mechanism 2 is connected on the sliding table, the feed pressing assembly 3 is connected with the rotating mechanism 2, and the bottom end of the feeding pressing assembly passes through the barrel assembly 4 and extends into the plasticizing chamber 5.

[0035] like figure 1 As shown, the rotating mechanism 2 includes a motor base 21 and a stepping motor 22. The motor base 21 is a rectangular seat with an open top, and its bottom end is provided with a through hole. The stepping motor 22 is assembled in the motor base, and the output shaft of the stepping motor After passing through the through hole, it is connected with the feeding pressure assembly 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com