Intelligent natural rubber machining system and intelligent natural rubber machining method thereof

A natural rubber and processing system technology, applied in the field of rubber processing, can solve problems such as reduced service life, difficulty in control, and cracking, and achieve the effects of ensuring the quality of finished products, weakening the calendering effect, and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

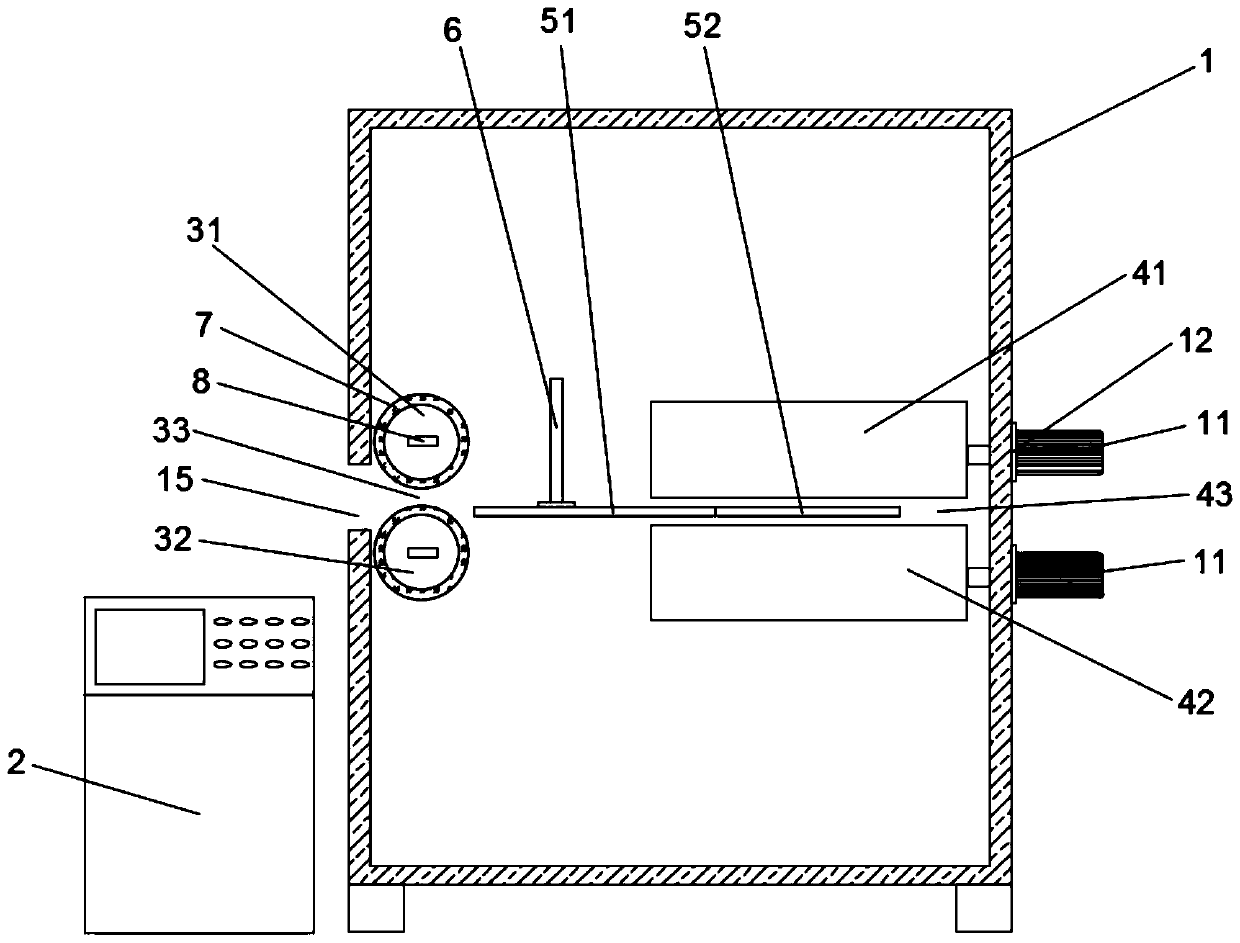

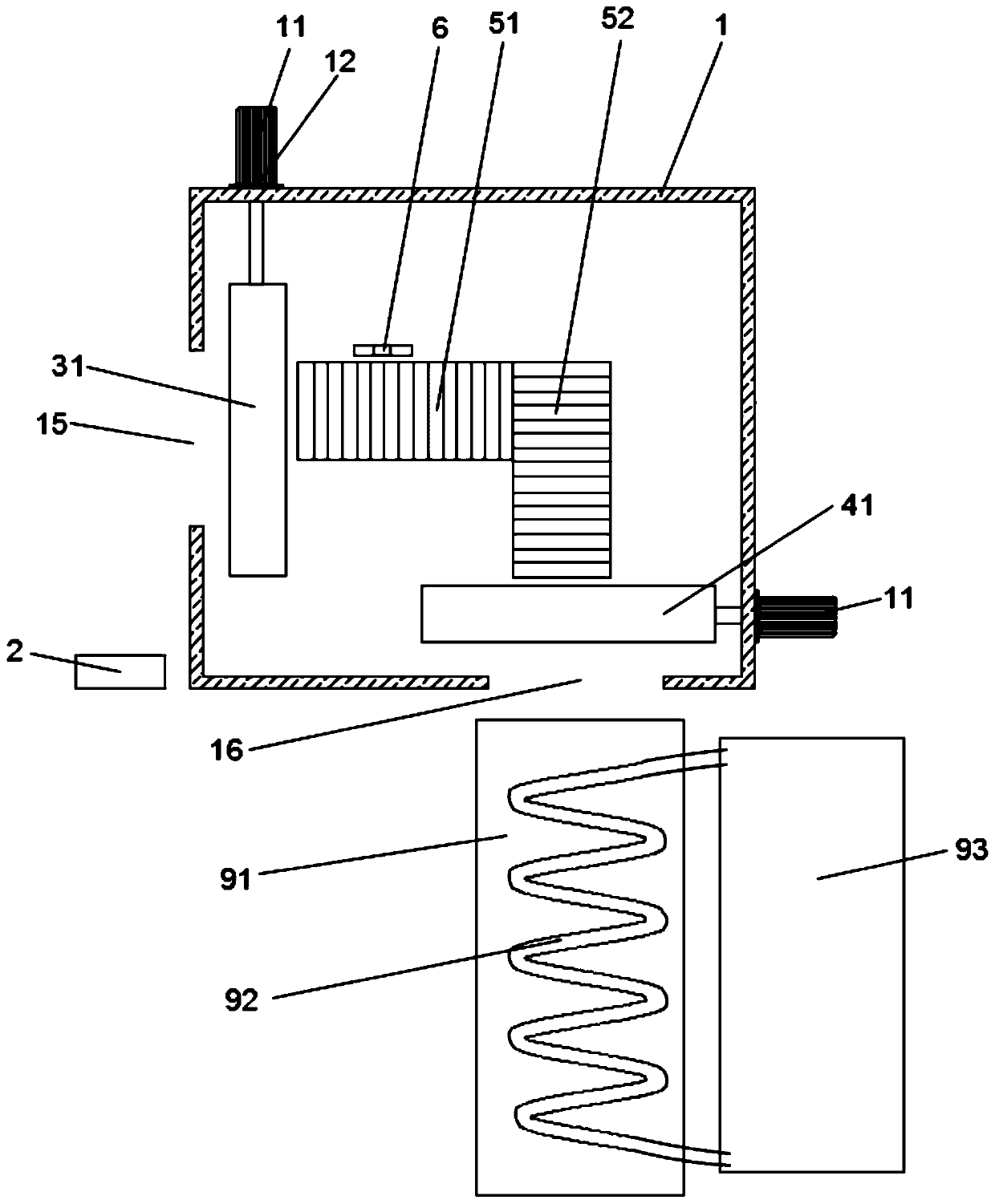

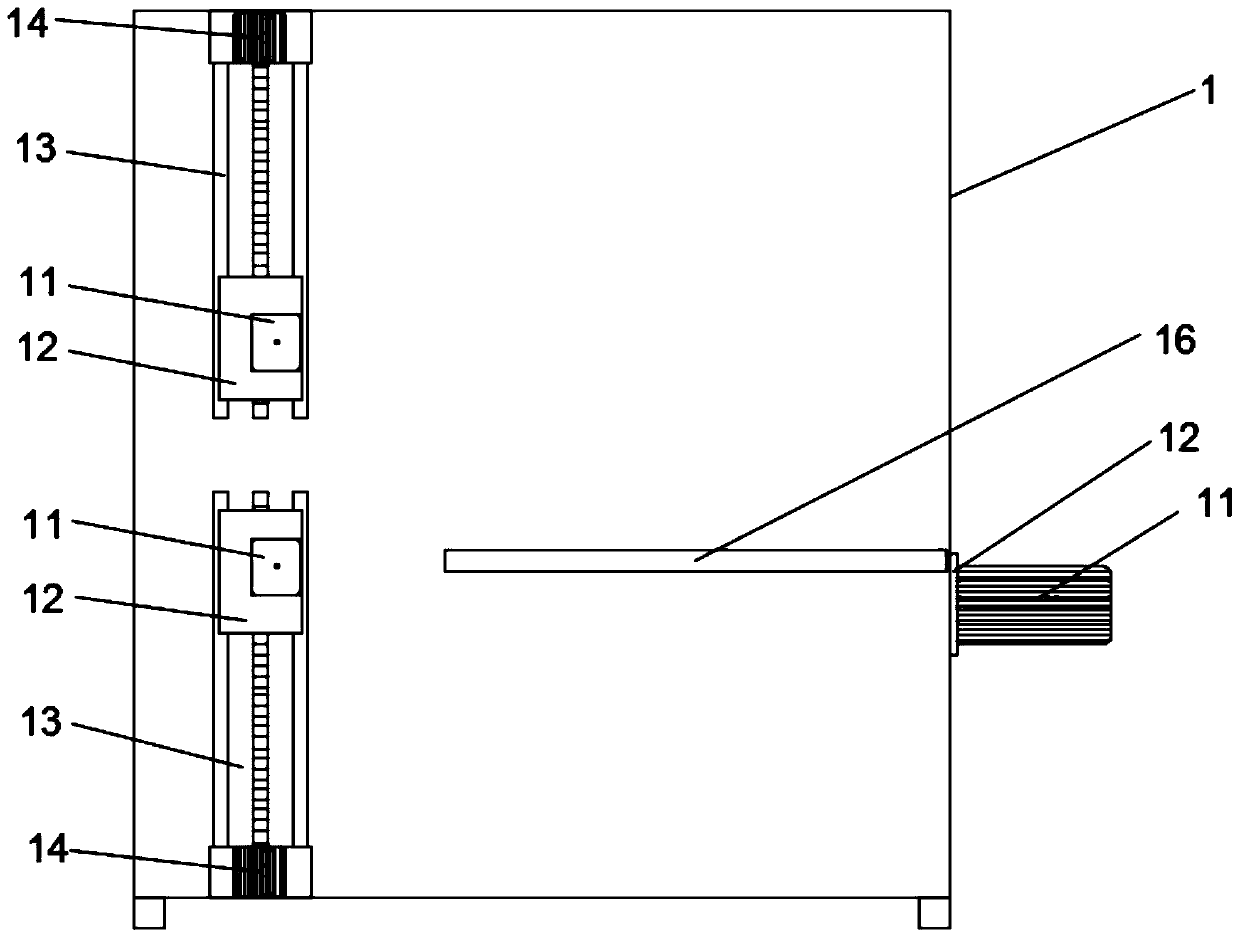

[0029] In order to better understand the technical content of the present invention, a specific embodiment is provided below, and the present invention is further described in conjunction with the accompanying drawings.

[0030] see Figure 1-Figure 4 , the natural rubber intelligent processing system provided by the present invention includes a calendering box 1 and a console 2, and the first roller set, the second roller set, a conveyor belt and a rubber material are arranged in the said calendering box 1. A cutting platform 6 for cutting, the conveyor belt is arranged between the first roller group and the second roller group, the cutting platform 6 is arranged on one side of the conveyor belt, and the axis of the first roller group is perpendicular to the second roller group The axes of the two roller groups, the console 2 is electrically connected with the first roller group, the second roller group, the conveyor belt and the cutting table 6 respectively; the first roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com