Expanding core fixture suitable for workpiece with gully on inner wall and use method thereof

A technology for expanding cores and workpieces, applied in the direction of expanding mandrels, etc., can solve the problems of high product failure rate, unqualified products, and difficulty in ensuring high coaxiality, so as to improve product qualification rate and production efficiency, and reduce damage. , the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

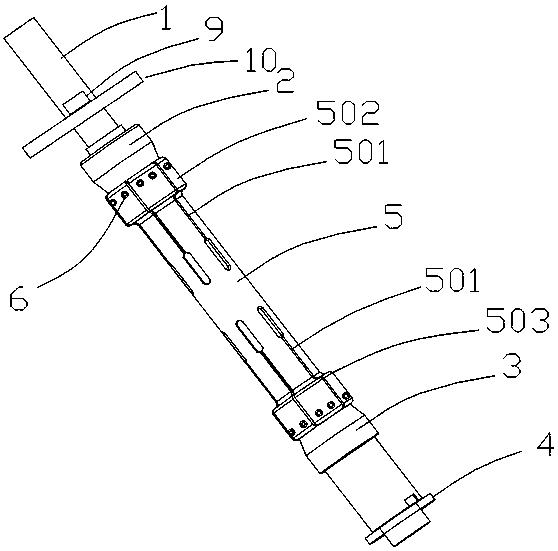

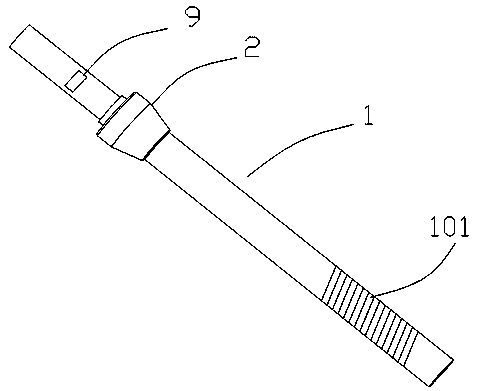

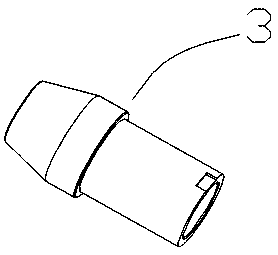

[0040] Such as Figure 1-5 As shown, a core expansion fixture suitable for workpieces with gullies on the inner wall is used to clamp the workpiece from the inner cavity, including: a concentric shaft 1 for support, a limit taper end 2 sleeved on one side of the concentric shaft, and a sleeve An active tapered end 3 located on the other side of the concentric shaft;

[0041] Wherein, the limit taper end is installed and fixed with the concentric shaft, and the movable taper end can slide along the concentric shaft, and an external thread 101 is provided on the side of the concentric shaft near the movable taper end, and an external thread 101 is provided on the concentric shaft. The outer thread section of the outer thread section is provided with a lock nut 4; the concentric shaft between the limit taper end and the movable taper end is provided with a tubular taper expansion core 5; the lock nut is used to push the movable taper end to the limit The end of the taper is appr...

Embodiment 2

[0053] A method of using a core expansion fixture suitable for workpieces with gullies on the inner wall. When in use, align the inner cavity of the workpiece with the concentric shaft, feed it in from the side of the movable taper end, and tighten the lock nut until the workpiece is against the positioning plate. Make the side near the limiting taper end and the side near the movable taper end of the taper core successively complete the core expansion and fixation of the inner cavity of the workpiece; after the expansion core fixture starts to rotate, the movable block under the action of centrifugal force The bottom is separated from the permanent magnet piece, and the head of some movable blocks enters the groove on the inner wall of the workpiece, thereby completing the further fixing of the workpiece.

[0054] After the expansion core fixing operation is completed, the lock nut should still be partially exposed outside the workpiece, so that it is convenient to use tools t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com