Active carbon adsorption tower

A technology of activated carbon adsorption tower and tower body, which is applied in the direction of gas treatment, membrane technology, and dispersed particle separation, etc. The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

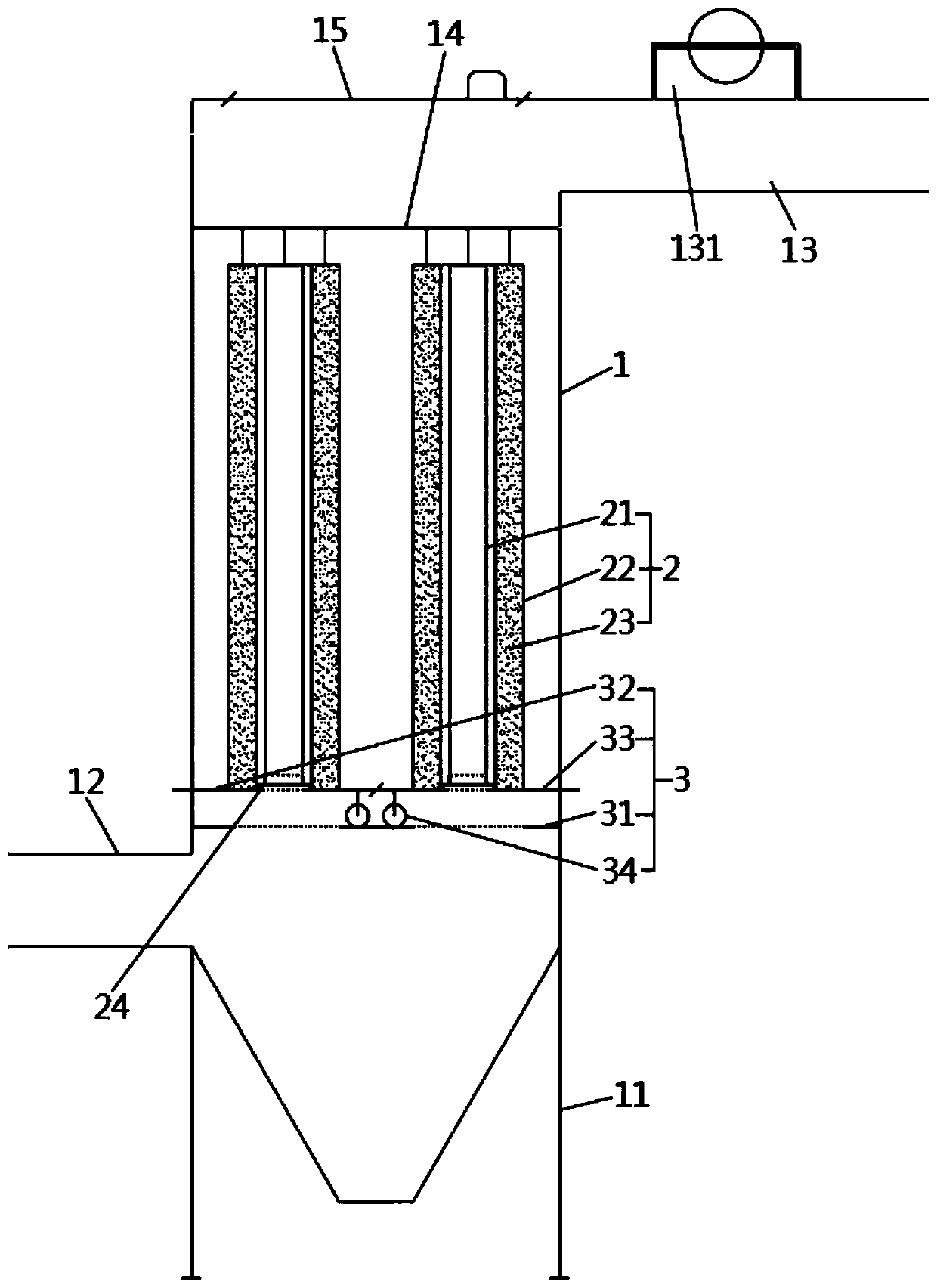

[0028] Example: such as figure 1 As shown, the activated carbon adsorption tower of this embodiment includes a tower body 1, the bottom of the tower body 1 is installed on the ground through a bracket 11, and a slagging outlet is provided at the bottom, and the lower end of the side wall of the tower body 1 has a flue gas inlet. 12, the upper end of the side wall is provided with a flue gas outlet 13; the filter assembly 2, the filter assembly 2 includes an inner filter element 21 and an outer filter cartridge 22 respectively installed inside the above-mentioned tower body 1, and the above-mentioned inner layer filter element 21 is a vertical It is a cylindrical structure with an open lower end, and the outer filter cartridge 22 is a cylindrical body with an open lower end, and is sleeved outside the inner filter element 21. The side wall of the outer filter cartridge 22 is a double-layer structure. And between the inner and outer two layers of side walls, a filling filter cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com