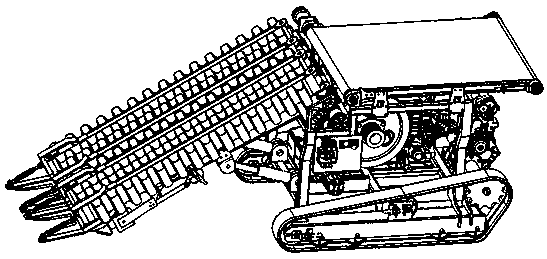

Crawler-type self-walking double-row cabbage harvester

A crawler-type harvester technology, which is applied to the harvester, the chassis of agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of harvesting damage, poor self-adaptability, and transportation bottlenecks, and achieve low-loss harvesting and improved harvesting efficiency , The effect of reducing labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes. This solution is mainly suitable for the mechanized harvesting of cabbage. It can realize the functions of straightening guidance, cutting, conveying, and collecting. It effectively integrates various functional modules, realizes the coordinated control of each link, and improves the automation level and self-adaptive ability of harvesting operations. .

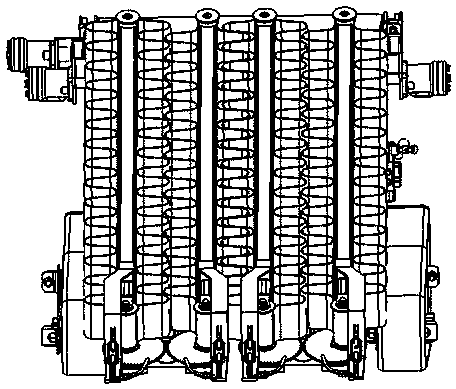

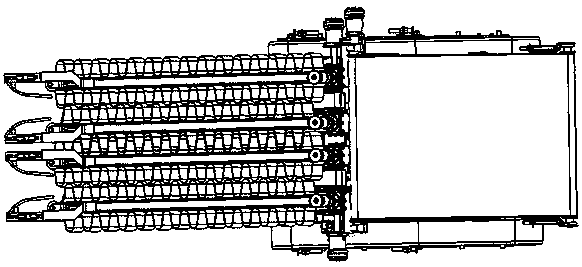

[0029] Such as Figure 1~4 A crawler-type self-propelled double-row cabbage harvester of the present invention includes a chassis assembly with a crawler-type walking device and a conveying assembly installed on the chassis assembly, and the conveying assembly includes a The two clamping conveyors in front of the assembly and the horizontal conveyor extending backward from the output ends of the two clamping conveyors, the clamping conveyors are installed obliquely and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com