Magnetic strip for electromagnetic oven

A technology of induction cooker and magnetic strip, applied in electric/magnetic/electromagnetic heating, electric heating devices, electrical components, etc., can solve the problems of reducing the service life of magnetic strips, uneven density, thickness, low heating efficiency at the connection, etc. Service life, reduce the probability of cracking, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

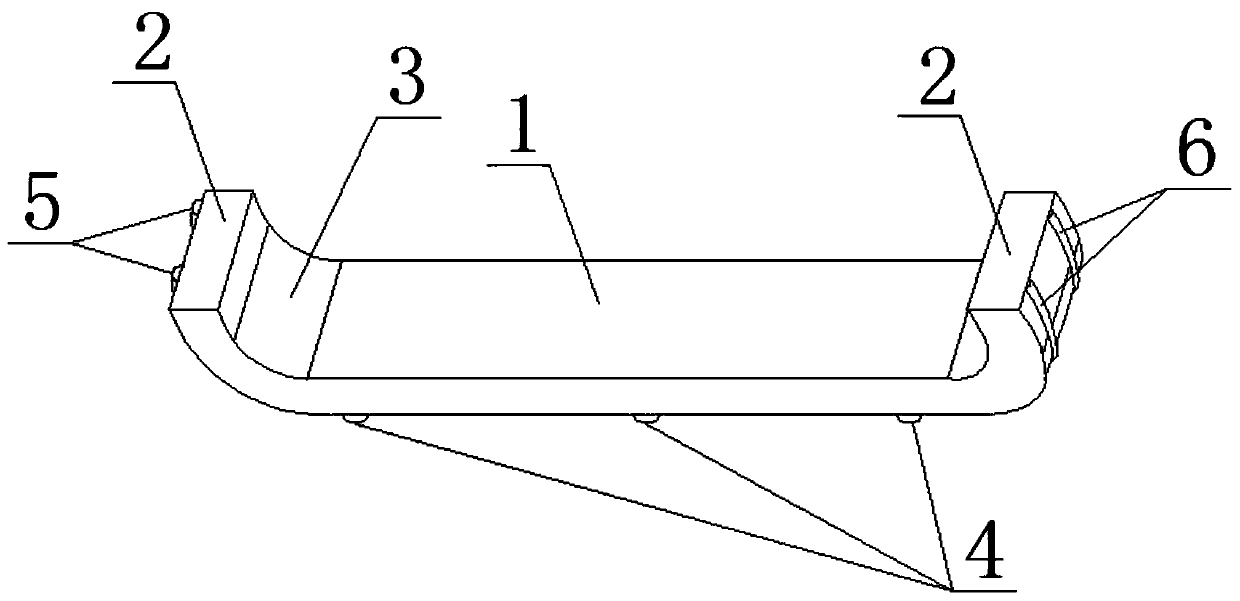

[0013] Such as figure 1 As shown, a magnetic strip for an induction cooker includes a horizontal part 1, two vertical parts 2, two arc-shaped transition parts 3, two reinforcing ribs B5 and two reinforcing discs C, and the two vertical parts 2 are respectively Two transition parts 3 are connected to the two ends of the horizontal part 1, the inner surface of the transition part 3 is smoothly transitioned with the inner surface of the horizontal part 1 and the inner surface of the vertical part 2 respectively, and the outer surface of the transition part 3 is connected with the horizontal part respectively. The outer surface of 1 and the outer surface of the vertical part 2 are smoothly transitioned; the outer surface of the horizontal part 1 is evenly connected with three reinforcing ribs A4 along its length direction;

[0014] Two reinforcing ribs B5 are evenly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com