2D Ti3C2-MXene thin film material, preparation method thereof and application of material in resistive random access memory (RRAM)

A technology of resistive memory and thin film materials, applied in electrical components and other directions, can solve the problems of increasing power consumption and complexity of peripheral circuits, difficulty in preparing multi-component compound films, poor adhesion between films and substrates, etc., and achieves easy modification. and treatment, the preparation process is non-toxic, and the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

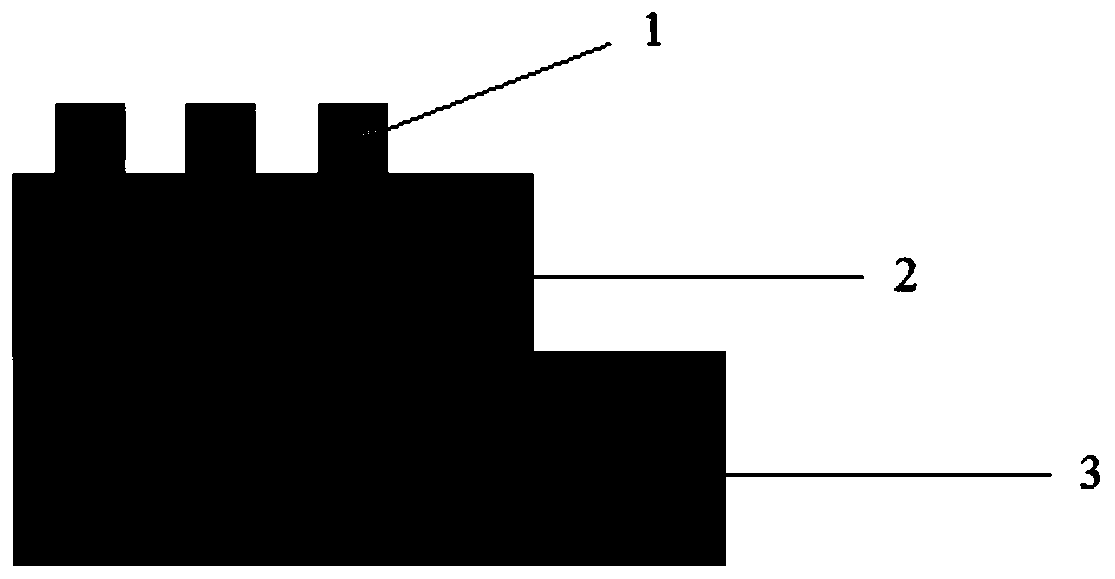

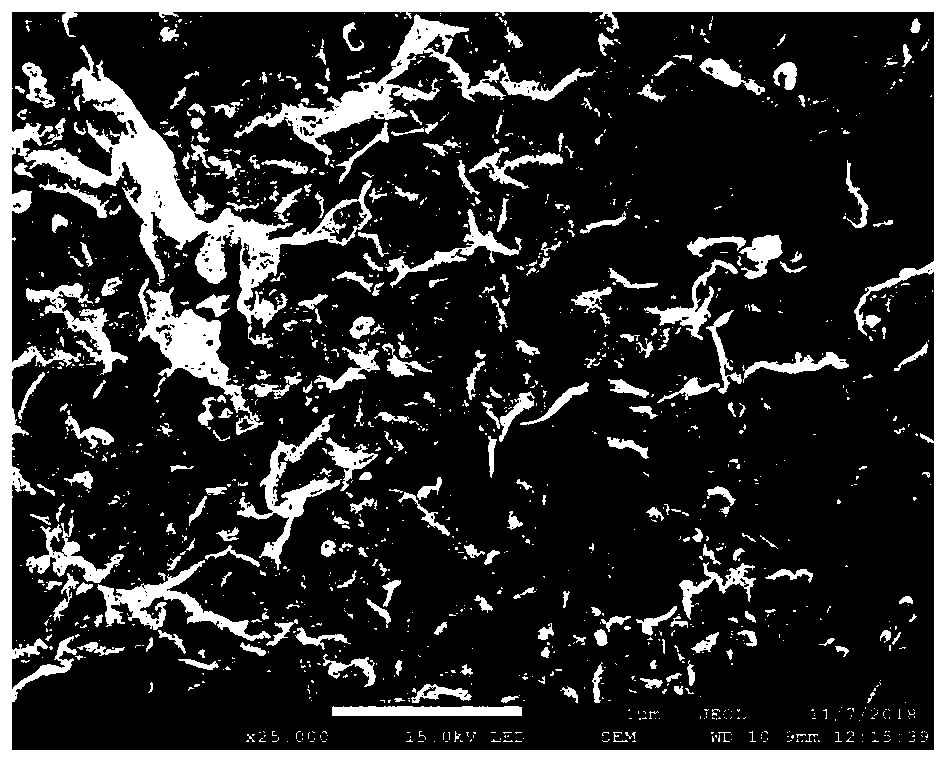

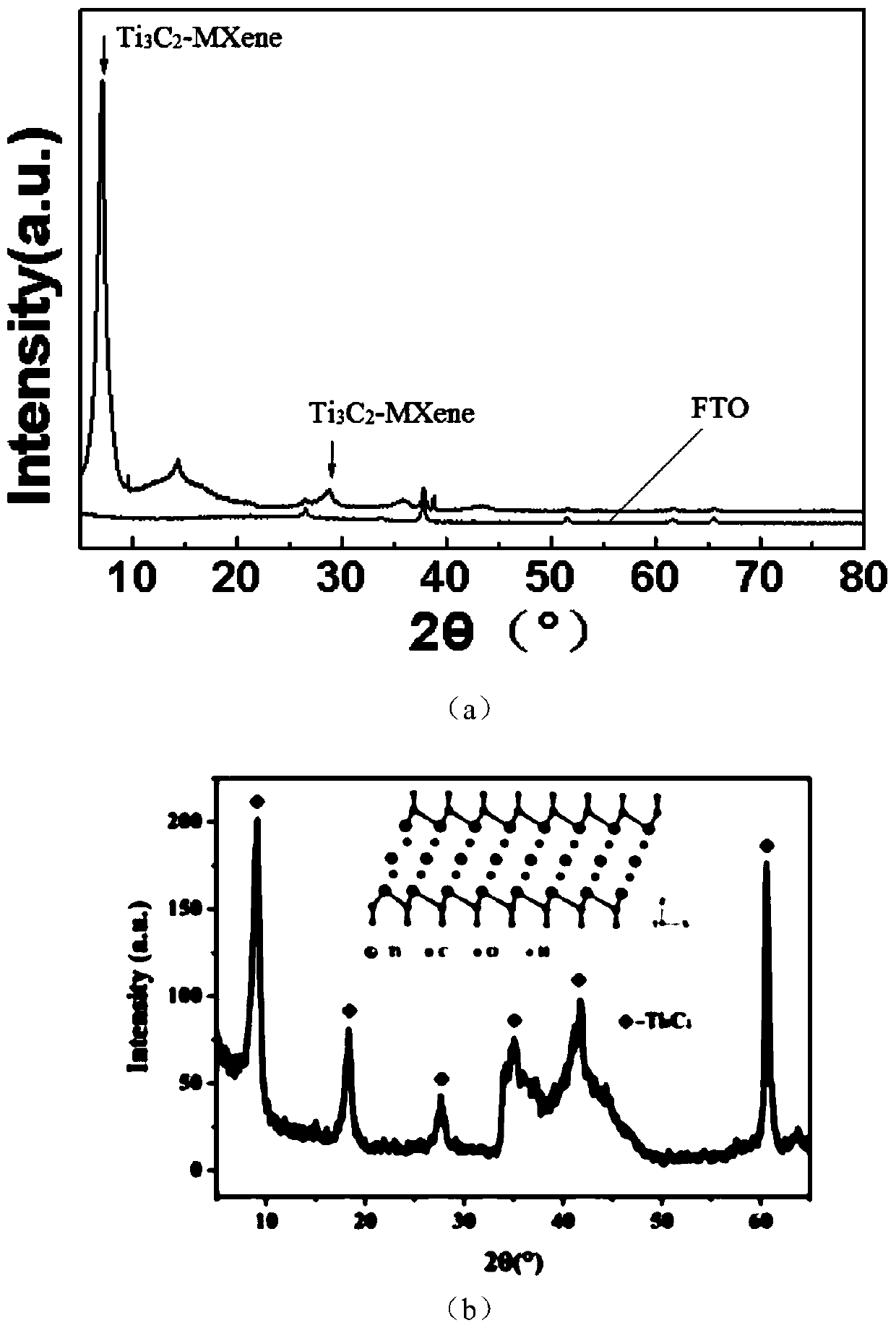

[0052] A two-dimensional Ti of the present embodiment 3 C 2 -The preparation method of MXene film material, comprises the steps:

[0053] Step 1. Clean the FTO (fluorine-doped tin oxide) conductive glass substrate

[0054] The first step is to tape a thickness of 100nm and a sheet resistance of 14Ω sq -1 The bottom electrode of the FTO and the square conductive glass with a side length of 1cm are ultrasonically cleaned in a mixed solution of detergent powder and deionized water for 15 minutes. In the second step, take out the FTO conductive glass and put it in a mixture of hand sanitizer and deionized water Ultrasonic cleaning for 15 minutes. In the third step, take out the FTO conductive glass and put it into acetone for ultrasonic cleaning for 15 minutes. In the fourth step, put the FTO conductive glass in ethanol solution and ultrasonically clean it for 15 minutes.

[0055] Step 2. UV treatment of FTO surface

[0056] Dry the above cleaned FTO, stick insulating tape on ...

Embodiment 2

[0065] A two-dimensional Ti of the present embodiment 3 C 2 -The preparation method of MXene film material, comprises the steps:

[0066] Step 1. Clean the ITO conductive glass substrate

[0067] The first step is to tape a thickness of 200nm and a sheet resistance of 15Ω sq. -1 The ITO bottom electrode and the square conductive glass with a side length of 1.5cm are ultrasonically cleaned in a mixed solution of detergent powder and deionized water for 15 minutes. In the second step, take out the ITO conductive glass and put it into a mixture of hand sanitizer and deionized water Ultrasonic cleaning in medium for 15 minutes, the third step, take out the ITO conductive glass and put it in acetone for ultrasonic cleaning for 15 minutes, the fourth step, put the ITO conductive glass in ethanol solution and ultrasonic cleaning for 15 minutes.

[0068] Step 2. UV treatment of ITO surface

[0069] Dry the above cleaned ITO, stick insulating tape on the edge of the sheet to form a r...

Embodiment 3

[0077] A two-dimensional Ti of the present embodiment 3 C 2 -The preparation method of MXene film material, comprises the steps:

[0078] Step 1. Clean the AZO conductive glass substrate

[0079] The first step is to tape a thickness of 300nm and a sheet resistance of 20Ω sq -1 The AZO bottom electrode and the square conductive glass with a side length of 2cm are ultrasonically cleaned in a mixed solution of detergent powder and deionized water for 15 minutes. In the second step, take out the AZO conductive glass and put it in a mixture of hand sanitizer and deionized water Ultrasonic cleaning for 15 minutes. In the third step, take out the AZO conductive glass and put it in acetone for ultrasonic cleaning for 15 minutes. In the fourth step, put the AZO conductive glass in ethanol solution and ultrasonically clean it for 15 minutes.

[0080] Step 2. UV treatment of AZO surface

[0081] Blow dry the cleaned AZO, paste insulating tape on the edge of the sheet to form a reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com