Imprinted polymer for separation of perrhenate ions, preparation method and application thereof

A technology of imprinting polymers and perrhenate, which is applied in chemical instruments and methods, other chemical processes, and improvement of process efficiency, can solve the problems of not meeting urgent needs, low efficiency of separation and purification, and low purity of ammonium rhenate. Achieve the effects of improving low desorption rate and low reusability, simple preparation method, good practicability and economic prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

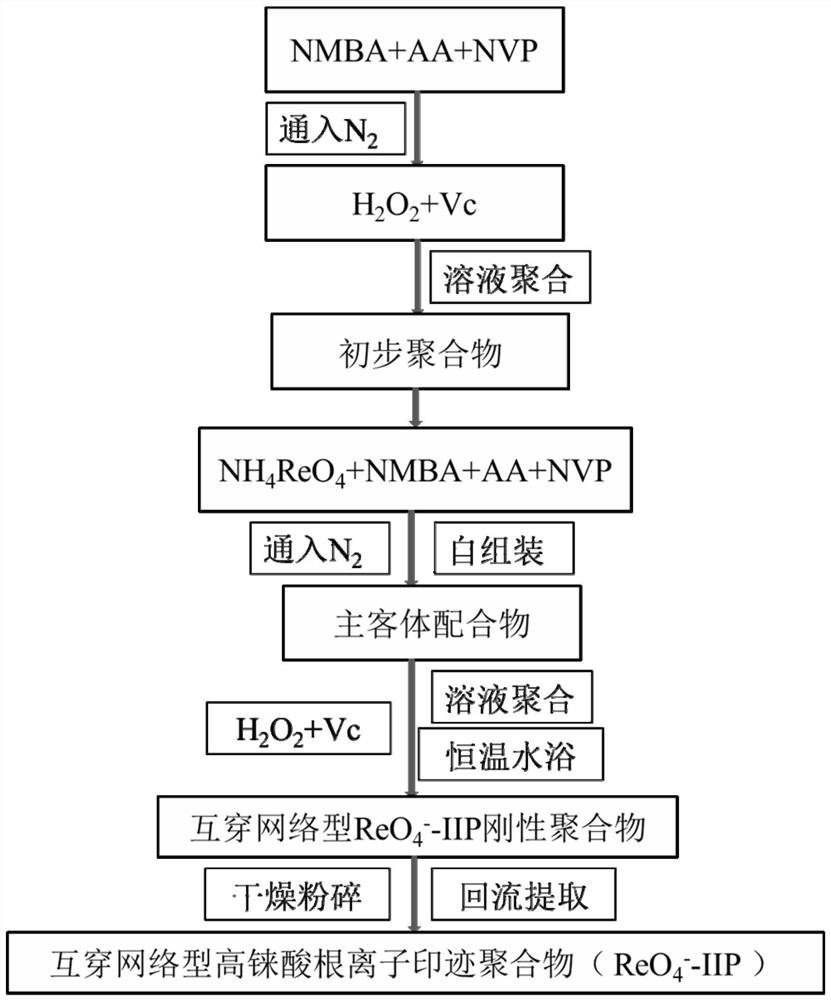

[0030] (1) Preparation of low-crosslinked polymer: Add 9mL of distilled water and 9mmol of N,N'-methylenebisacrylamide (NMBA) into a three-necked flask. After the NMBA is completely dissolved, add 9mmol of AA and 18mmol of NVP, feed N into the reaction system 2 15min, exclude oxygen, then add 1.2mL of H 2 o 2 -Vc initiator, react for 1.5h. During the whole reaction process, N was continuously fed into the reaction system 2 , and magnetic stirring;

[0031] (2)ReO 4 - -Preparation of IIP rigid polymer: After the reaction, open the rubber stopper of the flask and add 0.5mmol NH 4 ReO 4 , 28mL of distilled water and 35mmol of NMBA, after the NMBA is completely dissolved, add 30mmol of AA and 18mmol of NVP, and feed N to the reaction system 2 12min, then add 1.5mL of H 2 o 2 -Vc initiator to initiate the reaction; after reacting for 15 minutes under stirring conditions, stop stirring, and place the reaction system in a constant temperature water bath at 38°C to continue ...

Embodiment 2

[0037] (1) Preparation of low-crosslinked polymer: Add 6mL of distilled water and 6mmol of N,N'-methylenebisacrylamide (NMBA) into a three-necked flask. After the NMBA is completely dissolved, add 6mmol of AA and 20mmol of NVP, feed N into the reaction system 2 10min, exclude oxygen, then add 1mL of H 2 o 2 -Vc initiator, react for 2h. During the whole reaction process, N was continuously fed into the reaction system 2 , and magnetic stirring;

[0038] (2)ReO 4 - -Preparation of IIP rigid polymer: after the reaction, open the rubber stopper of the flask and add 0.35mmol NH 4 ReO 4 , 20mL of distilled water and 35mmol of NMBA, after the NMBA is completely dissolved, add 35mmol of AA and 20mmol of NVP, and feed N into the reaction system 2 10min, then add 1mL of H 2 o 2 -Vc initiator to initiate the reaction; after reacting for 12 minutes under stirring conditions, stop stirring, and place the reaction system in a constant temperature water bath at 35°C to continue t...

Embodiment 3

[0044] Take by weighing the 20g ReO that embodiment 1 prepares 4 - -IIP particles are packed into 200 mesh tea bags, and the tea bags are placed in a beaker containing 100mL 0.5mmol / L rhenium-containing alloy waste solution, the beaker is sealed, and then the reaction system is placed in a constant temperature water bath at 40°C. 10min time sampling is measured by ICP and the adsorption amount is calculated. At 25°C, the 4 - The adsorption capacity is 0.0807mmol / g. After the adsorption is over, it will be filled with ReO 4 - -Take out the IIP tea bag, rinse the surface of the tea bag with distilled water, then place the tea bag in a beaker containing 100mL of distilled water, and desorb it in a constant temperature water bath at 40°C for 8 hours. Its desorption rate is 72.65% at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com