Preparation method of bismuth system ceramic

A technology of ceramics and bismuth series, applied in the field of preparation of bismuth series ceramics, can solve the problems of easy volatilization of Bi elements, prone to impurity phase, uncertain performance test, etc., and achieve the effects of simple process operation, inhibition of volatilization, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

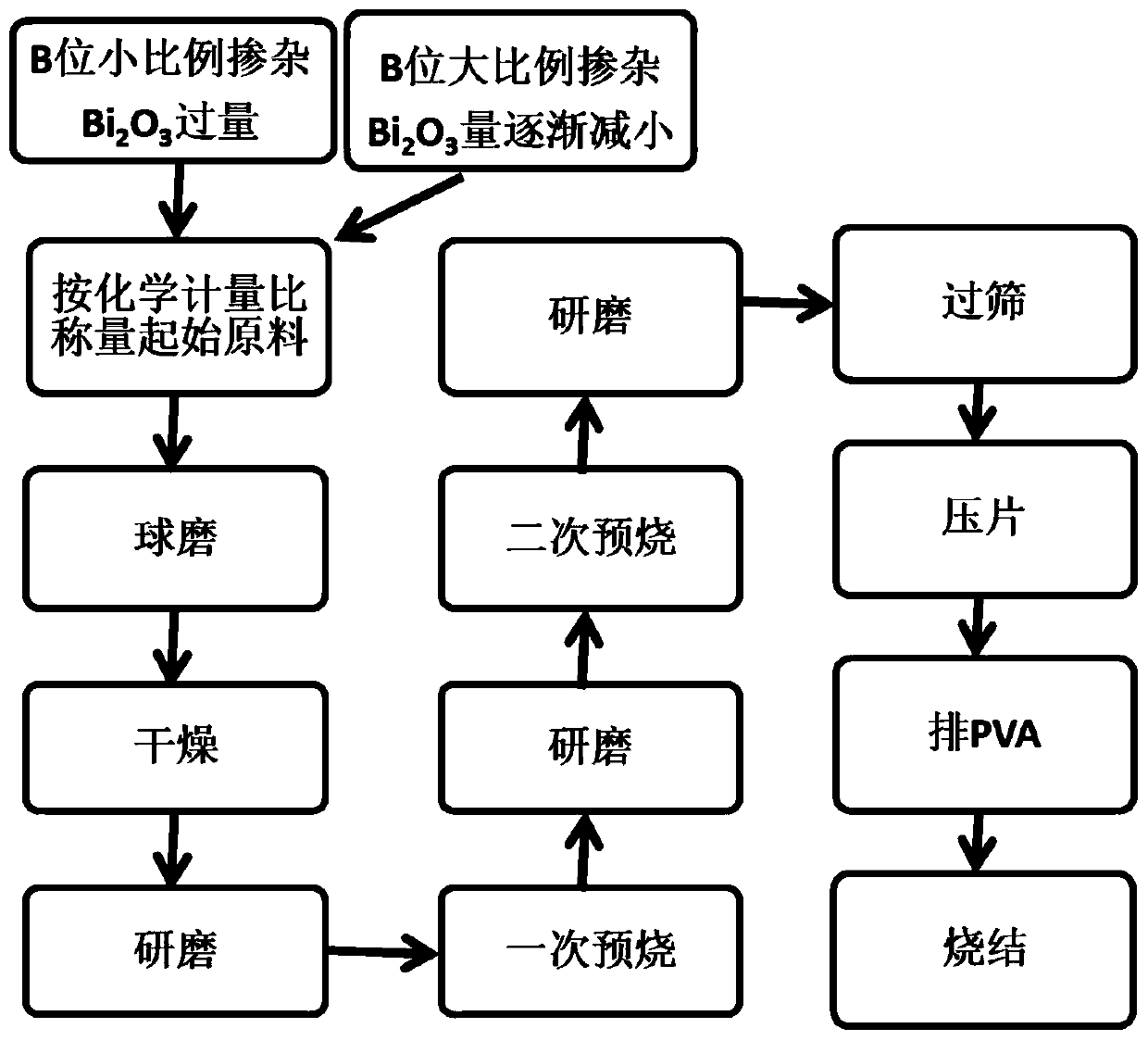

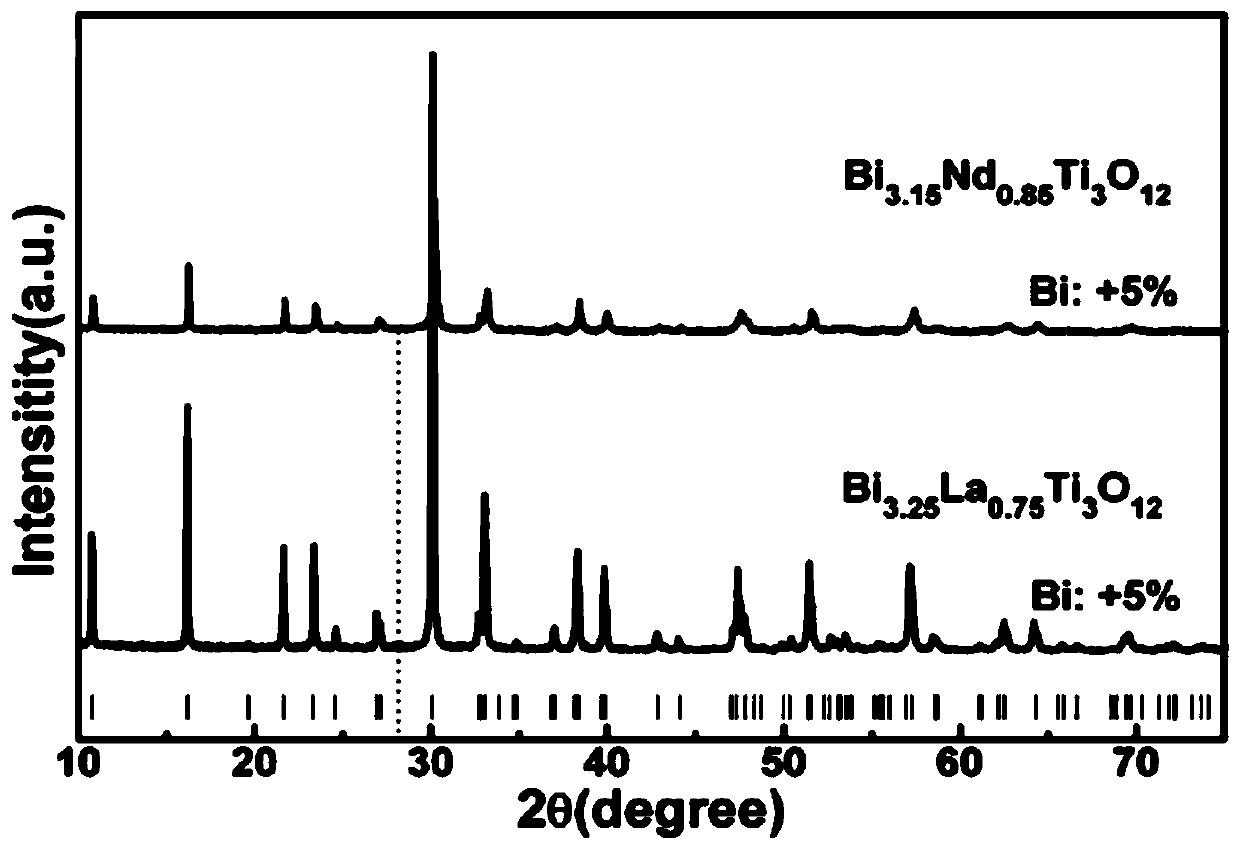

[0036] A method for preparing bismuth-based ceramics, comprising the steps of:

[0037] (1) Weighing the starting raw materials: Calculate the ratio of the high-purity oxide raw materials required for ceramics according to the stoichiometric ratio, where the ceramics are Bi 3.25 La 0.75 Ti 3 o 12 or Bi 3.15 Nd 0.85 Ti 3 o 12 , that is, the B site in the ceramic is not doped, and an excess of 5% of bismuth oxide is selected when the raw materials are mixed;

[0038] (2) Ball milling: put agate balls of three different specifications, large, medium and small, into the ball milling jar, put the weighed starting materials into the ball milling jar, pour absolute ethanol into the ball milling jar, and then Place the ball milling jar in an ultrasonic cleaner for ultrasonic oscillation; place the oscillating ball milling jar on a planetary ball mill for ball milling;

[0039] (3) Drying: Gently remove the lid of the milled jar and replace it with plastic wrap. The plastic wra...

Embodiment 2

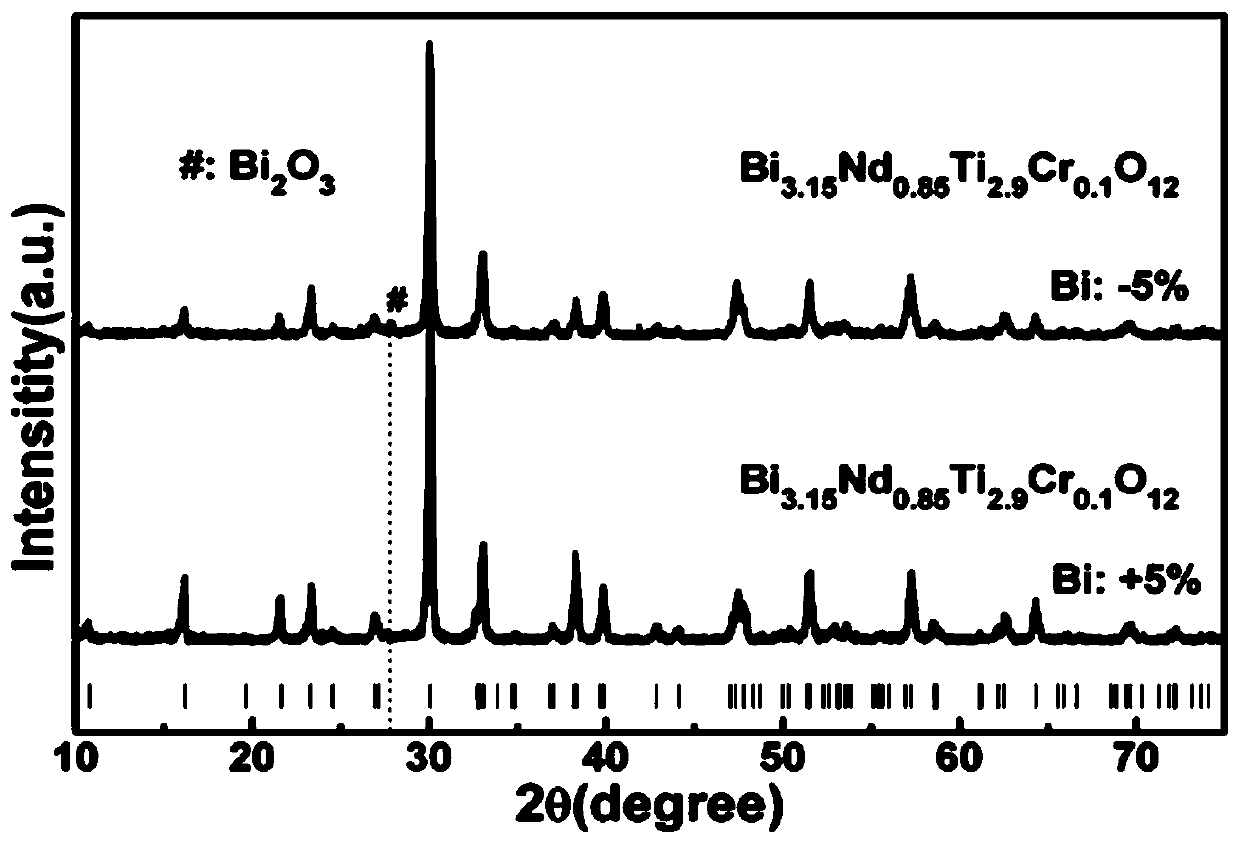

[0048] A method for preparing bismuth-based ceramics, comprising the steps of:

[0049] (1) The high-purity oxide raw materials required for ceramics are calculated according to the stoichiometric ratio, wherein the ceramics are Bi 315 Nd 0.85 Ti 29 Cr 0.1 o 12 , that is, the B-site ions in the ceramics are doped in a small proportion. In this embodiment, the doping amount is 0.1, and an excess of 5% of bismuth oxide is selected when the raw materials are mixed; at the same time, a small amount of 5% of bismuth oxide is selected for comparison when the raw materials are mixed. ;

[0050] (2) Ball milling: put agate balls of three different specifications, large, medium and small, into the ball milling jar, put the weighed starting materials into the ball milling jar, pour absolute ethanol into the ball milling jar, and then Place the ball milling jar in an ultrasonic cleaner for ultrasonic oscillation; place the oscillating ball milling jar on a planetary ball mill for ba...

Embodiment 3

[0060] A method for preparing bismuth-based ceramics, comprising the steps of:

[0061] (1) The high-purity oxide raw materials required for ceramics are calculated according to the stoichiometric ratio, wherein the ceramics are Bi 3.25 La 0.75 Ti 2.75 Fe 0.125 co 0.125 0 12 or Bi 3.15 Nd 0.85 Ti 2.75 Fe 0.125 co 0.125 o 12 , that is, the B-site ion doping amount in the ceramic is 0.25, and a small amount of 5% of bismuth oxide is selected when the raw materials are mixed;

[0062] (2) Ball milling: put agate balls of three different specifications, large, medium and small, into the ball milling jar, put the weighed starting materials into the ball milling jar, pour absolute ethanol into the ball milling jar, and then Place the ball milling jar in an ultrasonic cleaner for ultrasonic oscillation; place the oscillating ball milling jar on a planetary ball mill for ball milling;

[0063] (3) Drying: Gently remove the lid of the milled jar and replace it with plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com