Intelligent aluminum ingot delivering and boarding method, device and system

An aluminum ingot and warehouse-out technology, applied in storage devices, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, hidden safety hazards, etc., to solve safety problems, comprehensive automation and intelligence, improve handling and The effect of on-board efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

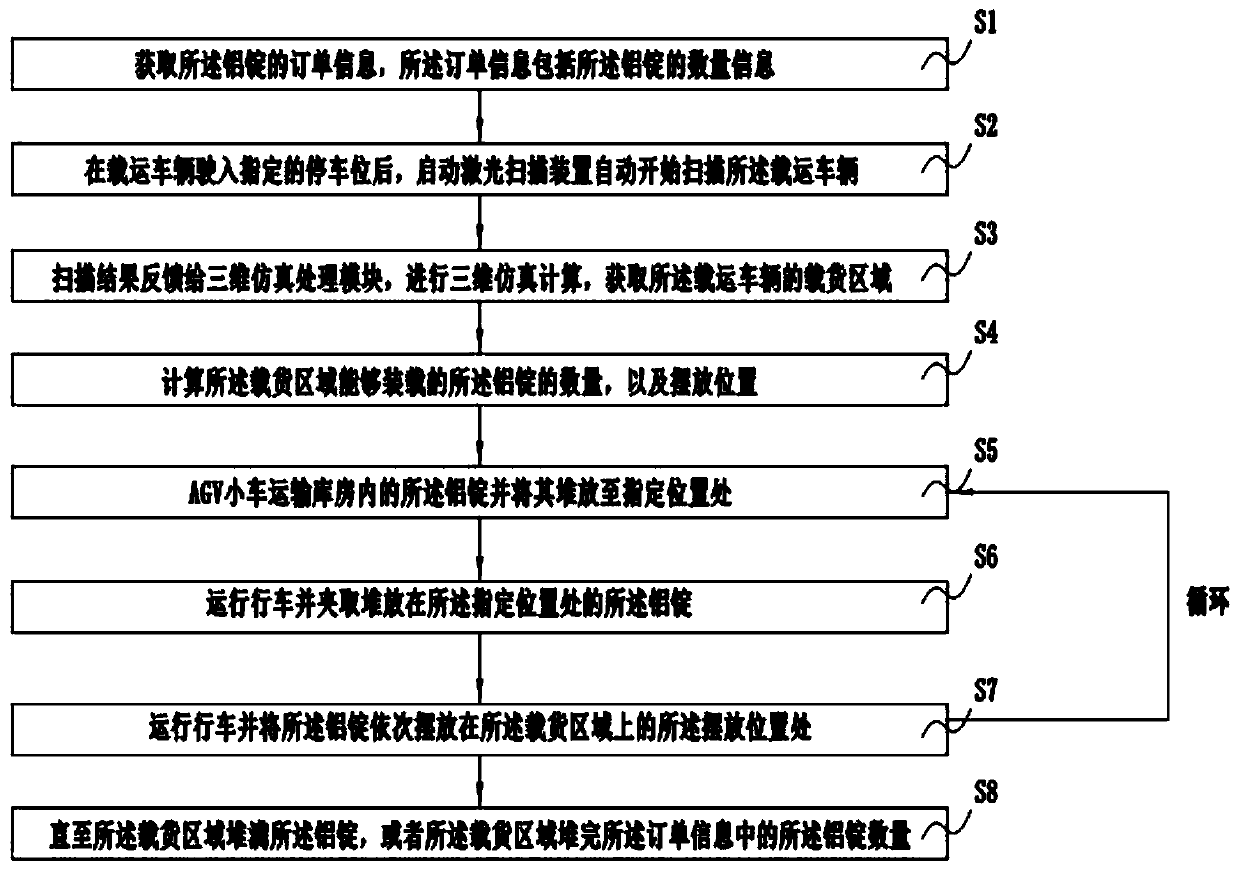

[0060] According to the embodiment of the present invention, there is an intelligent method for loading aluminum ingots out of the warehouse, please refer to figure 1 , the method of getting on the bus includes:

[0061] S1. Obtain order information of the aluminum ingot, where the order information includes quantity information of the aluminum ingot;

[0062] S2. After the carrying vehicle 8 drives into the designated parking space, start the laser scanning device 4 to automatically start scanning the carrying vehicle 8;

[0063]S3, the scanning result is fed back to the 3D simulation processing module, and the 3D simulation calculation is performed to obtain the cargo area of the delivery vehicle 8;

[0064] S4. Calculating the quantity of the aluminum ingots that can be loaded in the loading area, and the placement positions;

[0065] S5. The AGV trolley transports the aluminum ingots in the warehouse and stacks them to a designated location;

[0066] S6. Running the c...

Embodiment 2

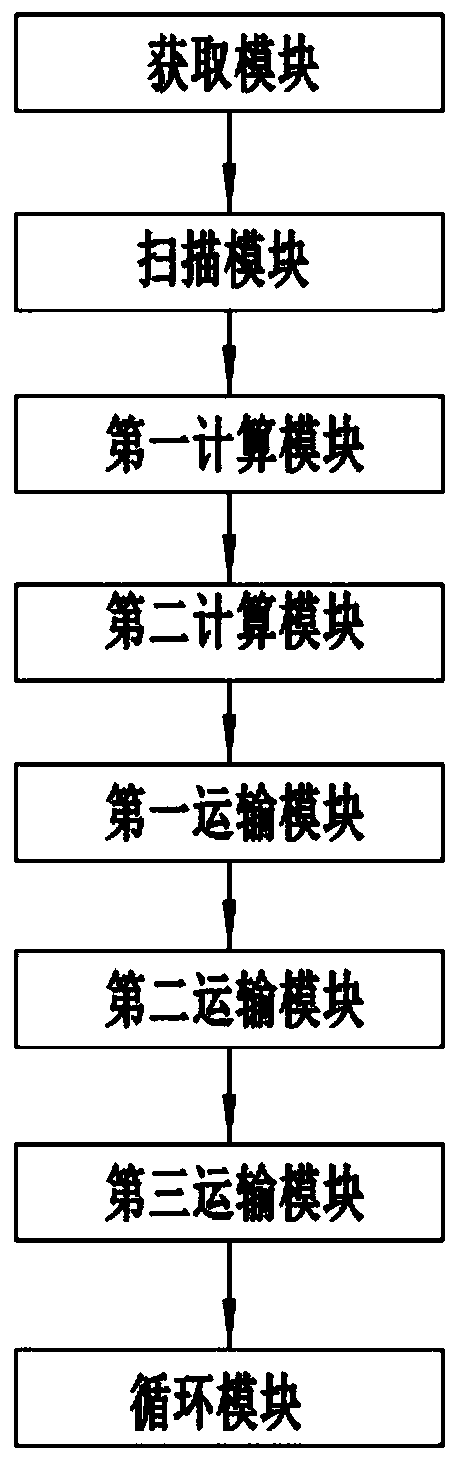

[0104] Embodiment 2 of the present invention provides a device, please refer to figure 2, the device includes: an acquisition module, configured to: acquire order information of the aluminum ingots, the order information including the quantity information of the aluminum ingots; a scanning module, configured to: after the carrying vehicle drives into the designated parking space , start the laser scanning device to automatically start scanning the delivery vehicle; the first calculation module is used to: feed back the scanning result to the three-dimensional simulation processing module, perform three-dimensional simulation calculation, and obtain the loading area of the delivery vehicle; the second calculation module, It is used for: calculating the quantity of the aluminum ingots that can be loaded in the loading area, and the placement position; the first transportation module is used for: the AGV trolley transports the aluminum ingots in the warehouse and stacks them to...

Embodiment 3

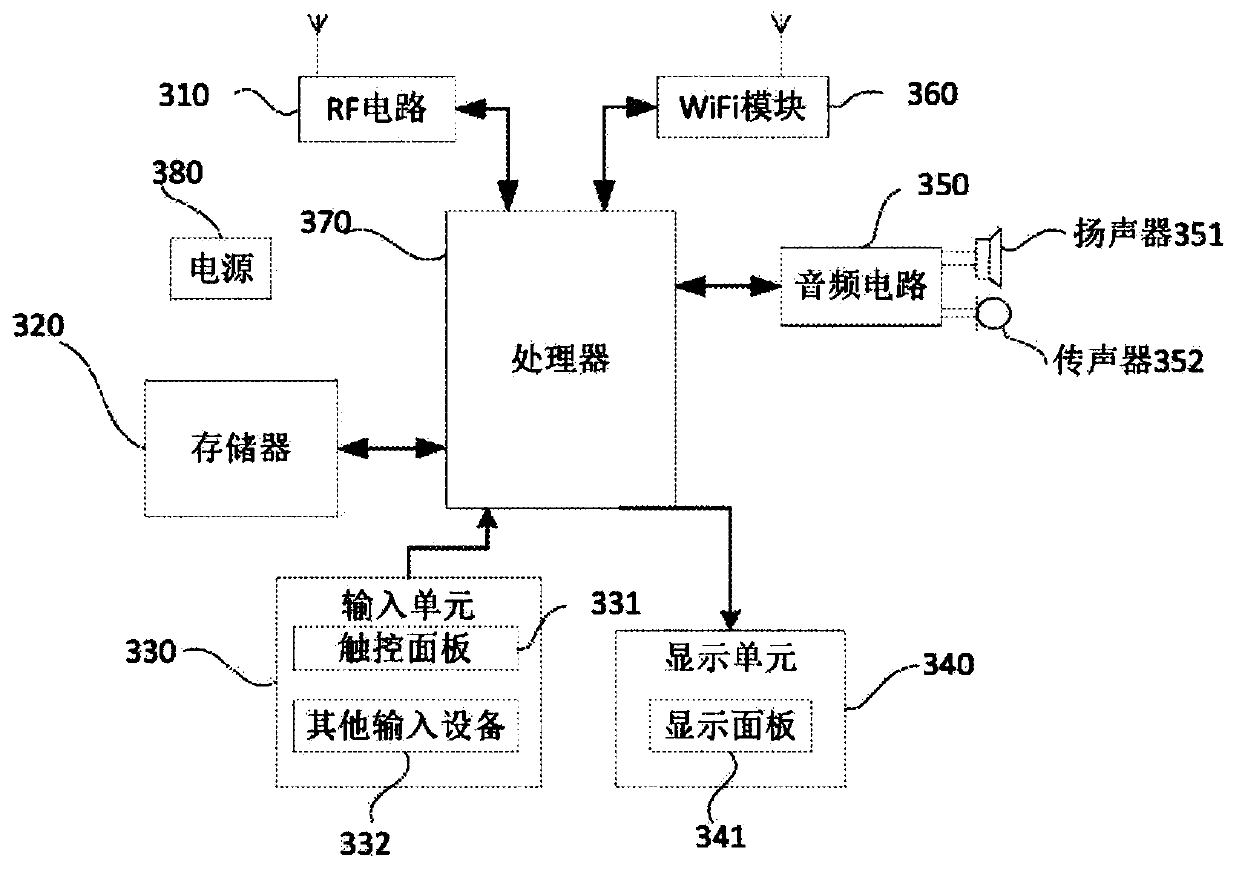

[0109] see image 3 It should be noted that, based on the same inventive technology as the first and second embodiments above, the third embodiment of the present invention provides a system, including: a radio frequency circuit 310, a memory 320, an input unit 330, a display unit 340, an audio circuit 350, WiFi module 360, processor 370, and power supply 380 and other components. Wherein, the storage 320 stores a computer program that can run on the processor 370, and the processor 370 implements the steps S1, S2, S3, S4, S5, S6, and S7 described in Embodiment 1 when executing the computer program. , S8.

[0110] In a specific implementation process, when the processor executes the computer program, any implementation manner in Embodiment 1 and Embodiment 2 may be implemented.

[0111] Those skilled in the art can understand that, image 3 The structure of the device shown in the device does not constitute a limitation to the device itself, and may include more or less com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com