Fiber reinforced thermoplastic composite material and preparation device and preparation method thereof

A composite material and fiber reinforced technology, applied in the field of composite materials, can solve the problems of inability to produce thickness, poor impregnation effect, and production of continuous fiber reinforced thermoplastic composite materials from plain fiber cloth, and achieve the effect of avoiding poor impregnation effect and good impregnation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

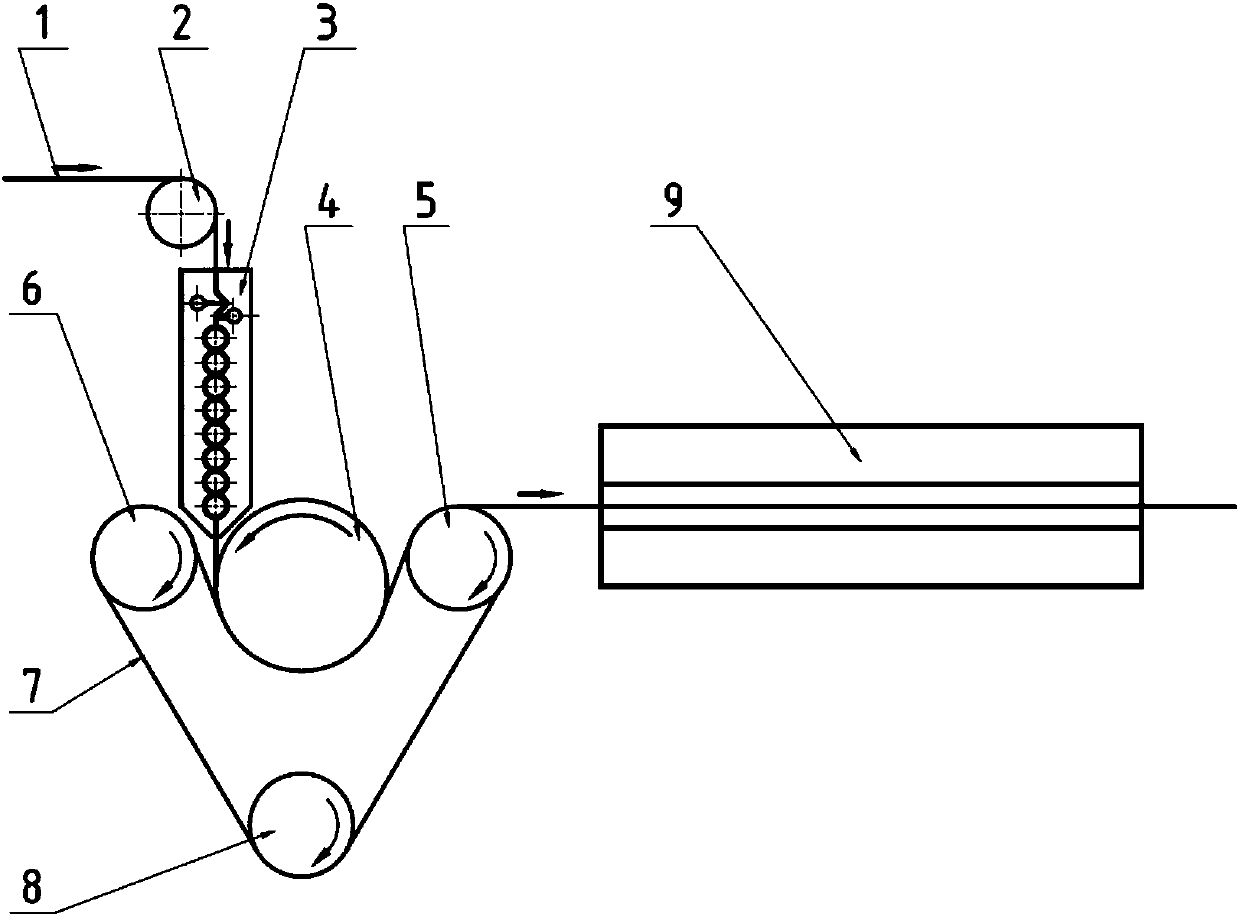

[0045] The method for preparing a fiber-reinforced thermoplastic composite material using the preparation device described in the above-mentioned embodiments comprises the following steps:

[0046](1) The fiber layer 1 is placed on the fiber spreading roller 2, drawn out through the fiber spreading roller 2 and unfolded, then enters the impregnation device 3, and the thermoplastic resin is coated thereon by the impregnation device 3;

[0047] (2) The fiber layer 1 coated with thermoplastic resin is discharged from the impregnation device 3, and enters the contact surface formed by the seamless stainless steel belt 7 and the forming roller 4 of the forming press 10, the seamless stainless steel belt 7 and the forming roller 4 Continuously pressurize the fiber layer 1 coated with thermoplastic resin to form it and transfer it to the heating tunnel 9 to remove internal stress. The temperature of the heating tunnel is set between 60°C and 80°C, and the heating time is 1.5 to 3 min...

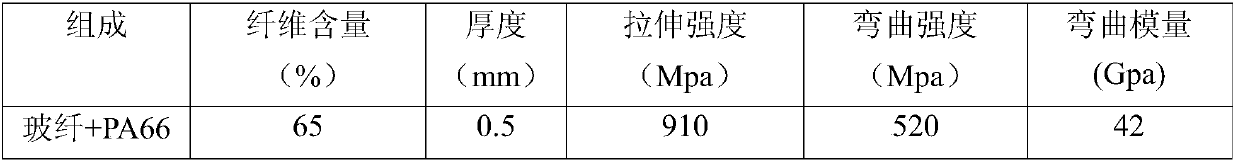

Embodiment 1

[0052] (1) Place the glass continuous fiber with a linear density of 2400tex on the fiber spreading roller 2, draw it out through the fiber spreading roller 2 and spread it into the impregnation device 3, and coat the PA66 resin on it through the impregnation device 3, the impregnation device The temperature of 3 is 300°C;

[0053] (2) The glass continuous fiber that has been coated with PA66 resin goes out by dipping device 3, and enters the contact surface that the seamless stainless steel band 7 of molding press 10 and forming roll 4 form, and described seamless stainless steel band 7 and forming roll 4 Continuously pressurize the glass continuous fiber coated with PA66 resin to make it shape, and transfer it to the heating oven 9 at a temperature of 200°C to remove internal stress, and obtain a composite material;

[0054] The production line speed of the entire preparation device is 3m / min, and the thickness of the prepared composite material is set to 0.5mm. The obtained...

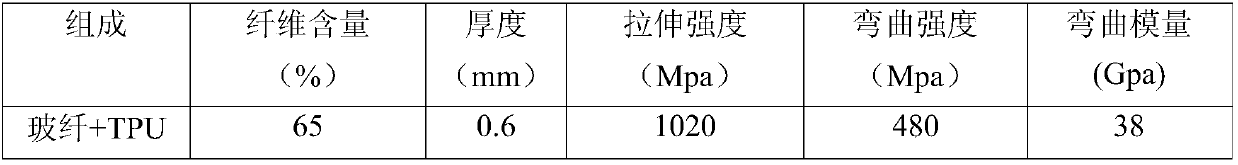

Embodiment 2

[0057] (1) Place the glass continuous fiber with a linear density of 2400tex on the fiber spreading roller 2, draw it out through the fiber spreading roller 2 and expand it and enter the impregnation device 3, and the TPU resin is coated on it by the impregnation device 3, and the impregnation device The temperature of 3 is 220°C;

[0058] (2) The glass continuous fiber that has been coated with TPU resin goes out by dipping device 3, and enters the contact surface that the seamless stainless steel band 7 of forming press 10 and forming roll 4 form, and described seamless stainless steel band 7 and forming roll 4 Continuously pressurize the glass continuous fiber coated with TPU resin to make it shape, and transfer it to the heating oven 9 with a temperature of 150°C to remove internal stress to obtain a composite material;

[0059] The production line speed of the entire preparation device is 2m / min, and the thickness of the prepared composite material is set to 0.6mm. The ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com