0# block bracket prestress pre-pressing construction method

A prestressing and bracketing technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of long construction period, difficulty in water intake and hoisting, high cost, etc., and achieve the effect of ensuring the effect of preloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

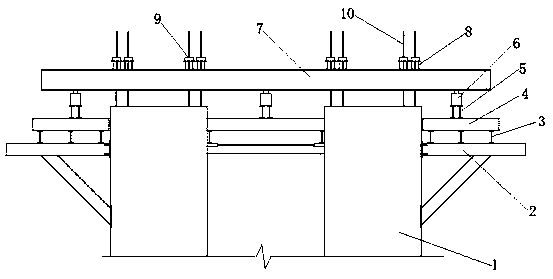

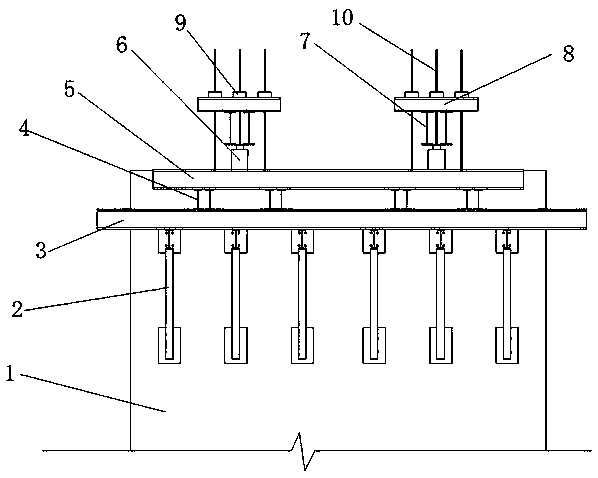

[0046] Refer to attached Figure 1-3 As shown, a 0# block bracket prestressing preloading method includes the following steps:

[0047] Step 1: Install the jack 6, the support frame and the reaction frame, place the support frame on the bracket 2, and connect the reaction frame to the pier body 1;

[0048] Step 2: Set a dial indicator at the root of the horizontal section of bracket 2, and set a total station to detect the axis offset of pier body 1;

[0049] Step 3: Carry out baseline measurement before preloading, read the initial value of each dial indicator, and record the initial value of the total station;

[0050]Step 4: Pressurize the jack 6 times at intervals to 120% of the load. After each pressurization, keep reading the dial indicator and record the deviation of the pier body 1 axis in the total station.

[0051] In traditional construction, water tanks or sandbags are used for preloading. On the one hand, due to the limitation of the site and natural conditions,...

Embodiment 2

[0064] Please refer to Figure 1-3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment provides a method for erecting a support frame and a reaction force frame and optimizes the structure, making the whole more stable and more convenient to erect.

[0065] In this embodiment, step 1 includes the following steps:

[0066] Step 1.1: Install the bracket 2 on the pier body 1 through the pre-embedded plate and the connecting plate, and the brackets 2 on both sides of the pier body 1 are pulled through the fine-rolled threaded steel bars;

[0067] Step 1.2: Set up the horizontal I-beam on the bracket 2, lay the distribution beam 4 on the first horizontal I-beam 3, place the second horizontal I-beam 5 on the distribution beam 4, and place on the second horizontal I-beam jack6;

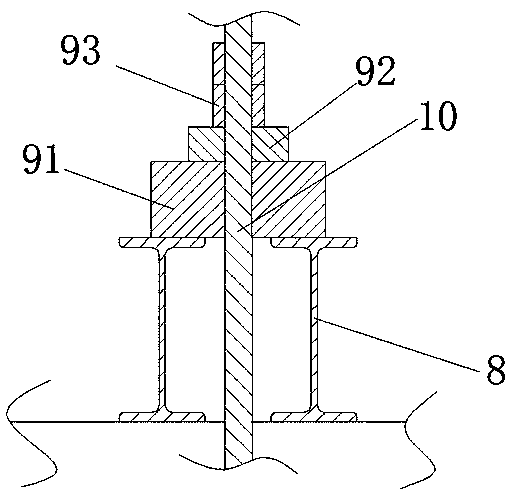

[0068] Step 1.3: Place the load-bearing beam 7 on the jack 6, place the shoulder-pole beam 8 on the load-bearing beam 7, and connect the shoulder-pole beam 8 to the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com