A kelp culture jig and float integrated jig to increase the culture density

A technology of breeding density and fixtures, which is applied in seaweed cultivation, horticulture, agriculture, etc., can solve the problems of low planting density and low efficiency, and achieve the effect of improving the ability of resisting waves and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

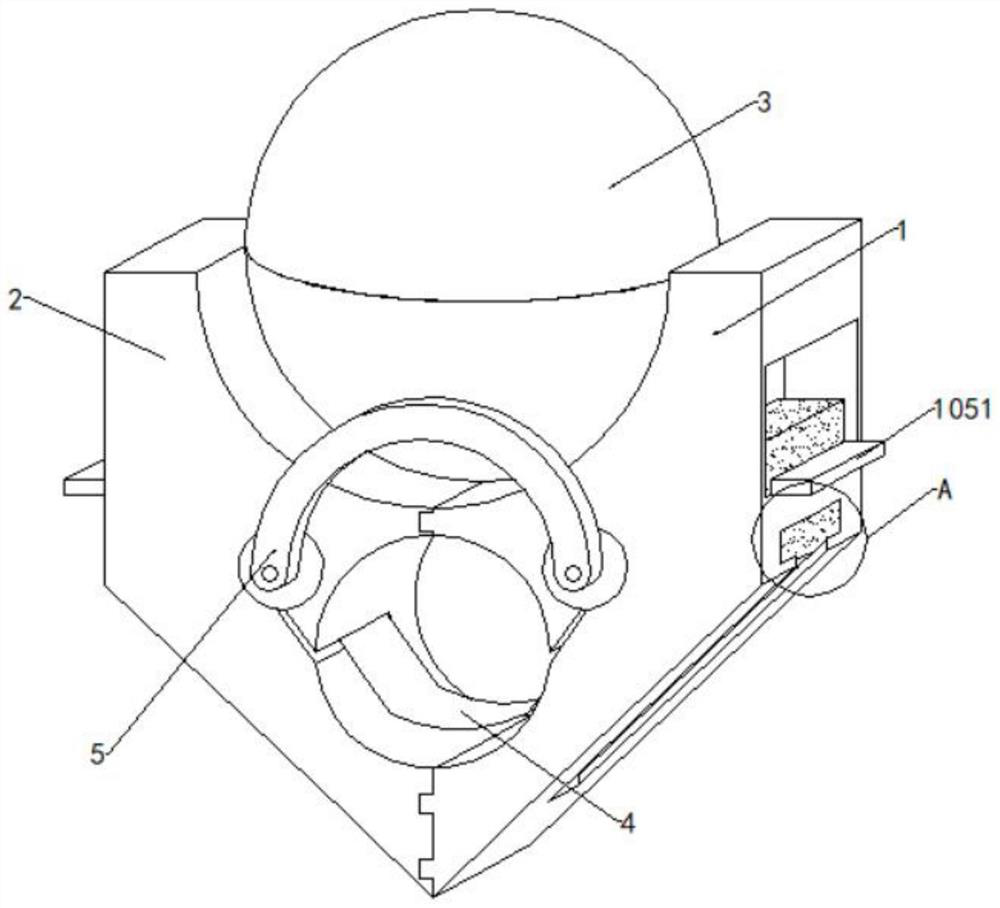

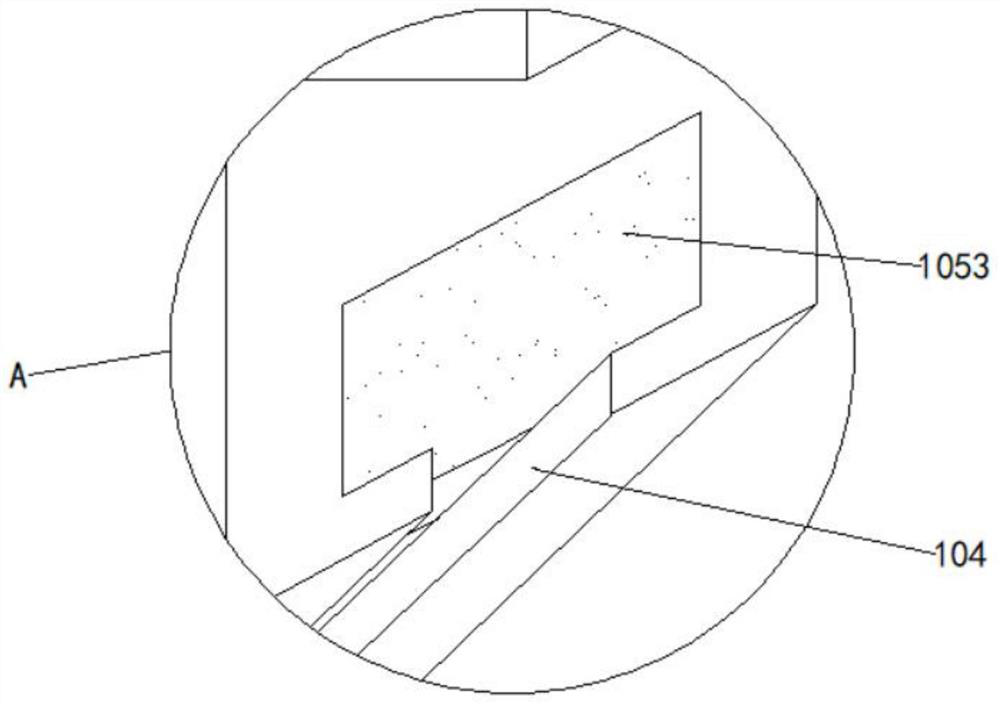

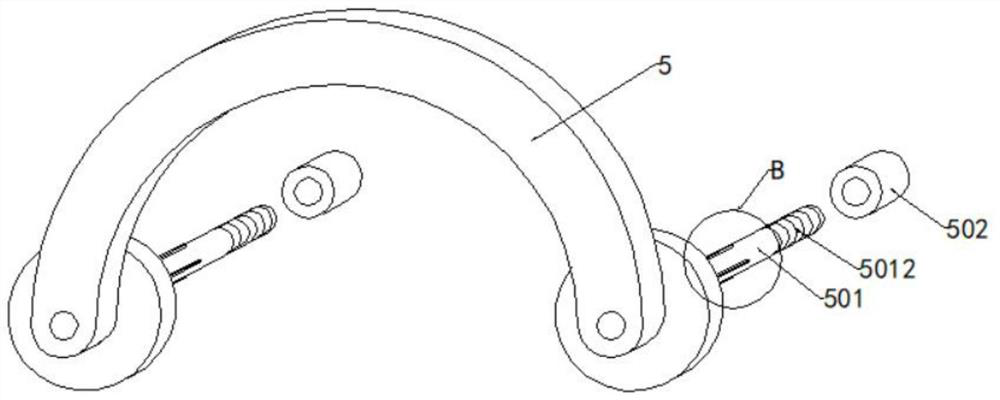

[0028] see Figures 1 to 9 , in the embodiment of the present invention, the purpose and effect of the integrated grinding machine of the present invention are achieved by the following specific technical means: a kelp culture jig and float integrated jig for increasing the culture density, including a device main body 1, a protrusion 101, a fixing hole 102, embedding groove 103, through groove 1031, insertion groove 104, operation panel 105, handle 1051, spring 1052, closing plate 1053, device auxiliary body 2, groove 201, float 3, spring coil 4, connecting plate 5, fixing Nail 501, thread protrusion 5012, stirring plate 5011 and nut 502, protrusions 101 are fixedly connected to the upper and lower ends of the left side of the device main body 1, grooves 201 are nested at the upper and lower ends of the right side surface of the device auxiliary body 2, and The protrusion 101 and the groove 201 are arranged in a snap-in connection, the left side surface of the device main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com