Power motor sealing structure for new energy automobile

A technology for new energy vehicles and power motors, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as oil seal lip ablation, motor seal failure, power motor failure, etc., to achieve improved sealing reliability and good lubrication Performance, the effect of ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

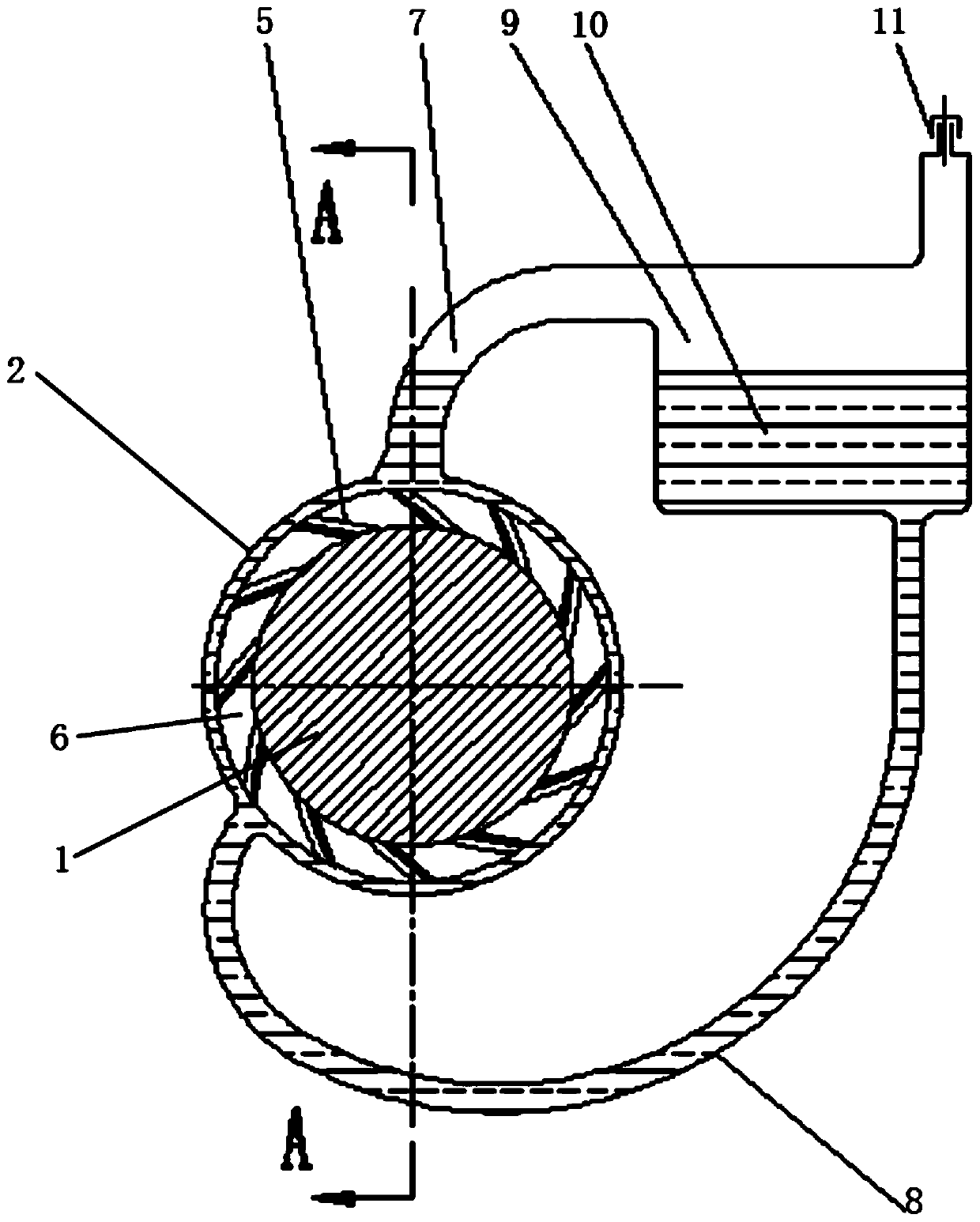

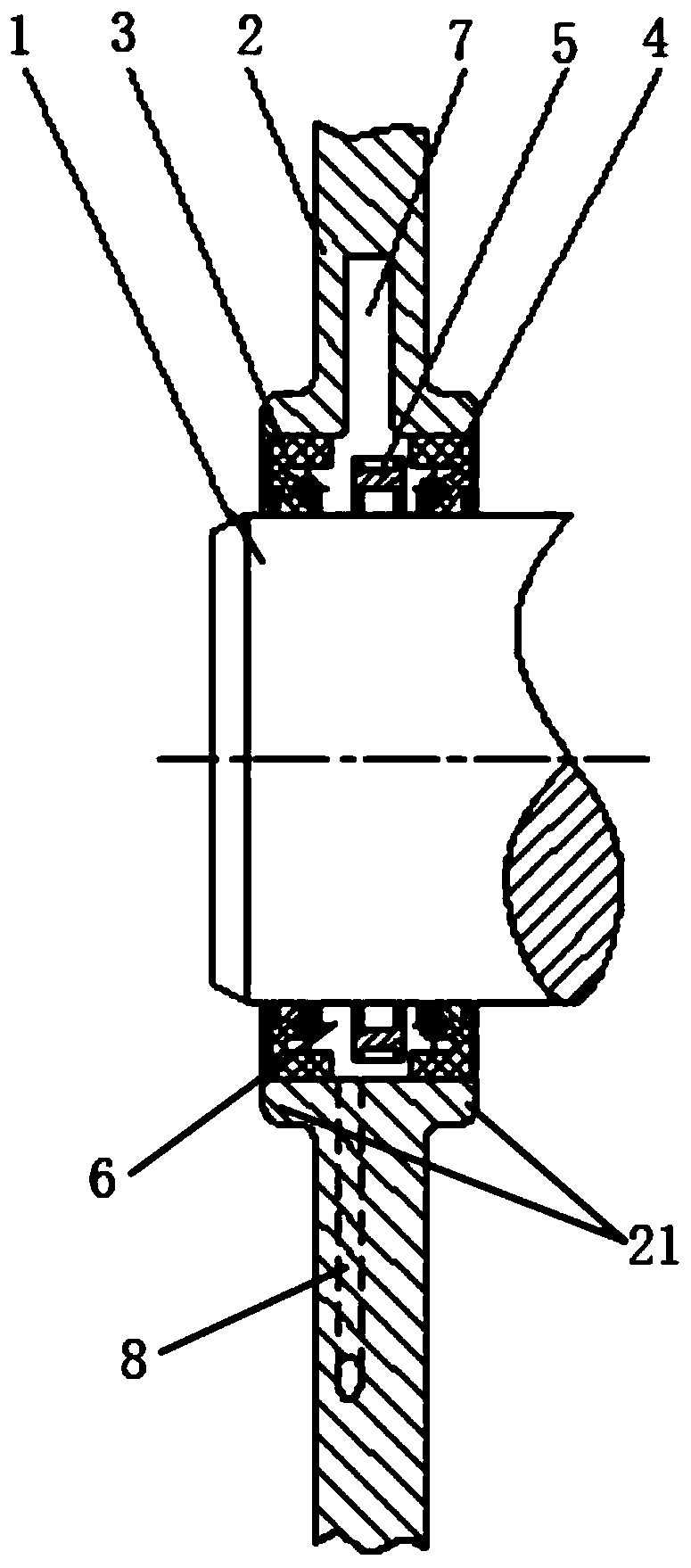

[0018] A new energy vehicle power motor sealing structure, see figure 1 , figure 2 : It includes a motor shaft 1 and a motor end cover 2, the motor shaft 1 runs through the center hole of the motor end cover 2, and the inner rings on both sides of the motor end cover 2 corresponding to the center hole of the motor shaft 1 are respectively provided with an inner oil seal 3 and an outer oil seal 4. There is a distance between the inner oil seal 3 and the outer oil seal 4. The motor shaft 1 runs through the inner oil seal 3 and the outer oil seal 4. The length of the motor shaft 1 between the inner oil seal 3 and the outer oil seal 4 is fitted with a pump blade rotor 5. The motor end cover 2 is provided with a pump chamber 6 corresponding to the outer peripheral area of the pump blade rotor 5. The pump chamber 6 is sealed by the inner oil seal 3 and the outer oil seal 4. The pump chamber 6 is connected with an oil outlet pipeline 7 and an oil return pipeline. 8, it also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com